Global transport company MAN Truck & Bus (MAN) has integrated Replique's 3D printing technology into its spare parts manufacturing strategy.

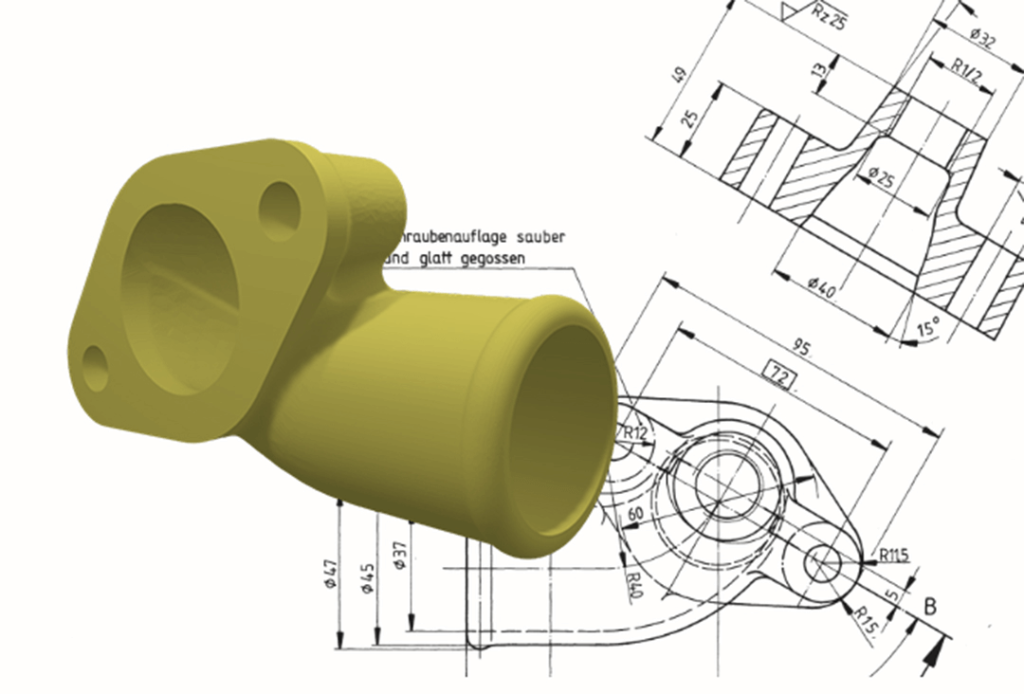

In partnership with Replique's manufacturing platform, the company engages in collaborative efforts to produce spare parts locally and on demand, thereby eliminating the need to maintain physical inventory. The immediacy became apparent when MAN urgently requested a quantity of 10 bronze manifolds, complicated by the lack of a conventional casting mold for this essential component. Recognizing the time and cost intensity of traditional delivery methods involving pattern making, casting and machining, MAN sought a more efficient solution, which led to the partnership with Replique.

“Working with Replique was seamless from our initial contact to the moment we received the finished parts. This allowed us to immediately help our customers with spare parts and we are already in the process of implementing another 3D printing project with Replique," says Thomas Hauck, MAN Spare Parts Logistics.

3D printing streamlines the production of spare parts

Using additive manufacturing technology, specifically Selective Laser Melting (SLM), MAN and Replique successfully reproduced the 10 manifolds in original quality with just a 3D model and production drawing. Replique, in alliance with material partners, selected material (m4p Brz10) equivalent to the original. The entire production, from the MAN inquiry to the delivery of the ready-to-install parts, took about 7 weeks. Subsequent tests at MAN's Central Material Technology department revealed that the selected material exhibited superior technical properties compared to the original, leading to an additional order for 10 units.

One notable advantage of 3D printed bronze manifolds is their ability to exceed the requirements of the original part. The digital availability of a qualified print file for this specific component ensures that manifolds can be produced at any time with consistent quality. MAN incurs no fixed costs for shapes and models or storage costs, providing an economically feasible solution for small quantities. MAN's adoption of 3D printing addresses the challenges of supplying spare parts within a dedicated machine design to reduce costs and improve overall service efficiency.

"Using additive manufacturing allows companies to overcome the challenges of traditional manufacturing. We are happy to work together with MAN to ensure a reliable and efficient supply of spare parts in the transport and marine sector," says Dr. Max Siebert, CEO and co-founder of Replique.

Accelerating innovation in the transport sector and at Deutsche Bahn

Industrial 3D printer manufacturer Essentium has received certification from Deutsche Bahn (DB), Germany's national railway, for its High Speed Extrusion (HSE) 3D printing platform and materials. Essentium's technology will be used to 3D print parts and tools for trains, allowing DB to improve fleet availability through rapid replacement of key components. Blake Teipel, CEO of Essentium, emphasized the readiness of additive manufacturing, highlighting DB's 3D printing of tens of thousands of train parts. DB plans to use Essentium's technology to address supply chain challenges and produce low-volume parts on demand, improving efficiency and reducing costs.

0 Comments