Auto body repair shops have the potential to 3D print any part for almost any car, but a lack of industry certifications is holding it back for now.

Waiting weeks and paying hundreds (even thousands) of leva for what seems like a simple but essential seal for your car is a frustrating experience. Today, these parts can be 3D printed quickly and cheaply, revolutionizing auto repair. However, quality certification has not kept pace with manufacturing reality, leading to potentially dangerous 3D printed car spare parts on the market, a new study has found.

This investigative report, called the "3D Printing In Collision Repair Task Force Report" by an association of automotive repair professionals, both praises 3D printing technology and warns against its misuse. His investigation found that unscrupulous parts retailers are already turning to fast and cheap 3D printing to produce aftermarket auto parts, but not labeling them as such. These parts often look like certified replacement parts, but fail in quality.

The automotive industry is embarking on a "transformational journey by incorporating 3D printing technology to produce end-use parts," the study found. But when it comes to the auto collision repair sector, more needs to be done "to avoid an influx of substandard, unregulated parts from unverified or unlicensed sources trying to take advantage of 3D printing."

Weighing the threat potential

In May, this task force, made up of automotive industry leaders in collision, 3D printing specialists and led by Harold Sears, an automotive industry veteran from Ford Motor Company who led large parts of the company's 3D printing implementation, set out to explored whether 3D printing would really make car repairs faster and cheaper, and if these benefits come with any drawbacks.

The group has come a long way to explore the effectiveness of 3D printing. It says he not only researched and interviewed stakeholders in the auto repair and additive manufacturing industry, but also visited 3D printing companies and conducted his own tests of 3D printed auto parts.

His findings were a huge endorsement of 3D printing for part manufacturing. The task force found that 3D printing presents "exciting opportunities that could revolutionize vehicle restoration, benefiting all stakeholders, from insurers and repair centers to OEMs."

Repairing damaged parts with missing components through 3D printing, the study found, reduces cost, time, waste, environmental impact, warehouse space and delivery, while increasing repair quality.

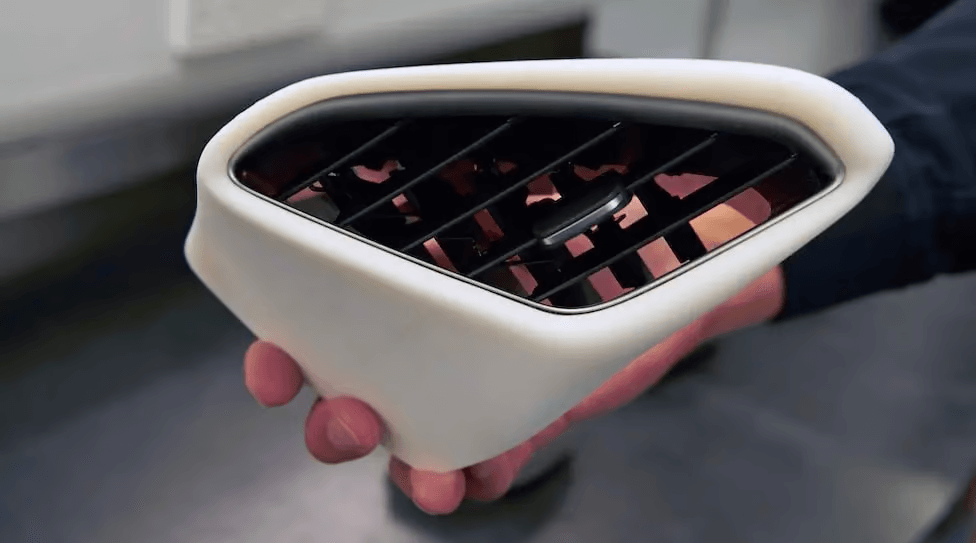

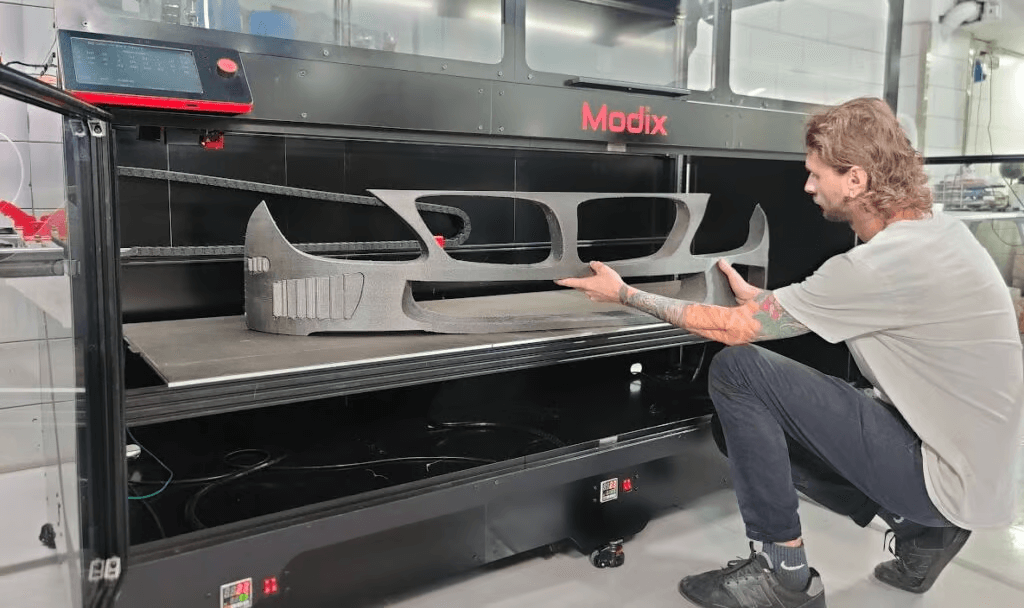

"Items such as headlight repair kits, bumper cover sensor sockets and high-value clips are very favorable for 3D printing applications," the report said. "Additionally, it can address the need for smaller, discontinued or out-of-stock parts that would otherwise require high-volume production using traditional methods."

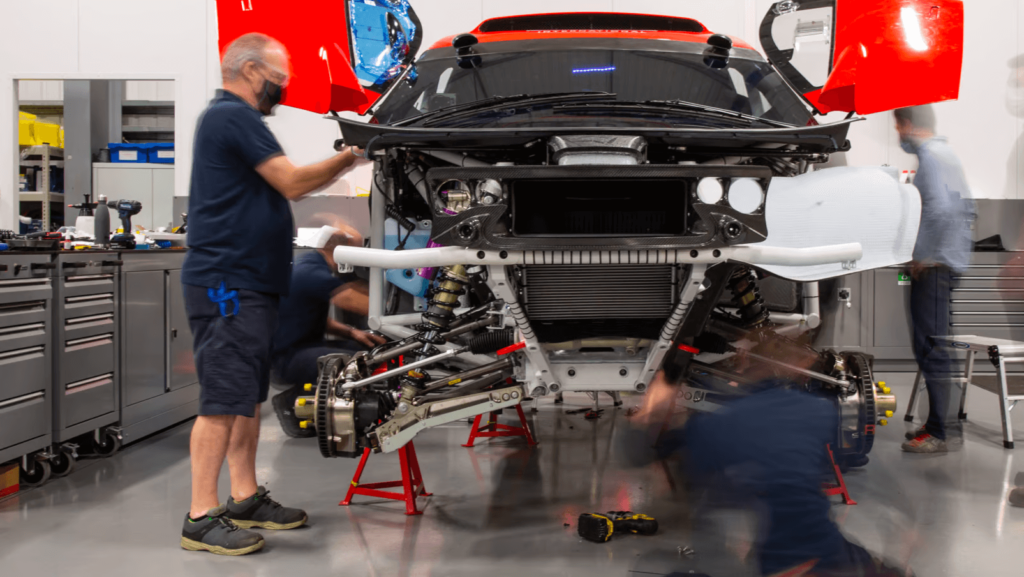

For auto repair shops, 3D printing technologies can enable the rapid production of virtually any polymer or metal replacement part for any make or model of vehicle.

But we're not there yet, the study warns, as no quality control or certification process exists yet to ensure that 3D-printed aftermarket auto parts meet specifications.

"It has been both exciting and somewhat disturbing to see the growing enthusiasm around 3D printing in the automotive parts industry," the report said. While the report doesn't name names, there's no shortage of files online for auto parts that anyone with a 3D printer can produce.

"By far the most concerning aspect of the ride to date is how widespread the use of low-quality materials and 3D printers is in vehicle repair processes," the report states. "Some people with low-end 'hobbyist' printers and supplies seem to think they can use parts of their printers as vehicle spare parts, replacing broken headlight plates, for example, or to start a business supplying 3D printing auto parts.”

3D printed fake auto parts

The task force conducted a test to see if 3D printed parts are already being sold in the auto repair industry. They purchased various headlight sections from online car suppliers from sites such as eBay. They found some 3D printed parts, although they weren't listed as such.

“More worryingly, some of these 3D printed parts were of such poor quality that they resembled a cardboard-looking headlight panel. They showed extremely poor surface finish as a result of using low-resolution, low-end scanners to perform reverse engineering functions.

3D printed parts are not inferior in quality to traditionally manufactured versions and in many cases can be better. However, the study found that some parts sellers were not using quality materials or processes.

From the vendors that openly offer 3D printed parts, there was no information about what technology or systems were used to produce them, what materials were used, or test data.

The risks to consumers of poorly made auto parts are significant. Other risks include safety concerns, insurance implications and legal liability.

"Increased claims and settlement costs may result from accidents caused by failure of non-standard 3D printed parts," the report noted. "This could lead to higher premiums for policyholders."

What can be done?

In the US, the National Highway Traffic Safety Administration (NHTSA) has specific regulations that apply to manufacturers of aftermarket auto parts, especially those related to safety-critical components such as brakes and lighting. Manufacturers may also be required to comply with the Federal Motor Vehicle Safety Standards (FMVSS) and obtain the necessary certifications.

Other standards and guidelines for aftermarket auto parts are set by industry-specific organizations or associations that provide certification programs or guidelines to ensure product quality and safety.

To ensure that the promise of 3D printing can be applied to the auto parts industry, the task force says the only way forward is with a series of safeguards in place, ranging from a governing body to establish quality control to banning the use of 3D printed parts in automotive repairs if not approved by OEMs or certified to recognized quality standards.

The auto collision repair industry is seeing the benefits of 3D printing, but only if the technology is implemented through a safe and regulated 3D printing supply chain.

The study's conclusion: "While this excitement and innovation holds the potential for future benefits in parts, materials or 3D printers, short-term uncertainties outweigh the potential opportunities, especially when it comes to ensuring that final parts meet a yet-to-be-established vehicle standard." "

0 Comments