This revolutionary development presents an ingenious approach to the "Design for Additive Manufacturing" principle, significantly challenging conventional manufacturing paradigms.

In contrast to conventional manufacturing techniques, the Cukurel team and the Turbomachinery and Heat Transfer laboratory took advantage of the potential of AM in its purest form. In his words, “When you use [AM] just as another manufacturing technique, you're not really taking full advantage of the benefits of additive manufacturing.” Instead of simply integrating AM as an alternative tool, the team reimagined it as a core resource, creating projects to satisfy the constraints and take advantage of AM.

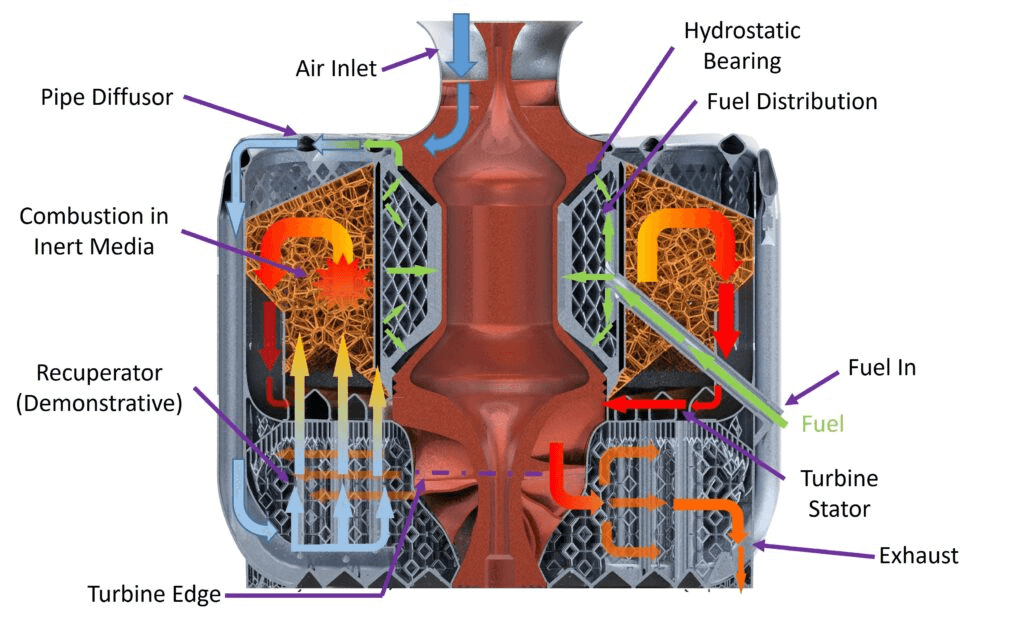

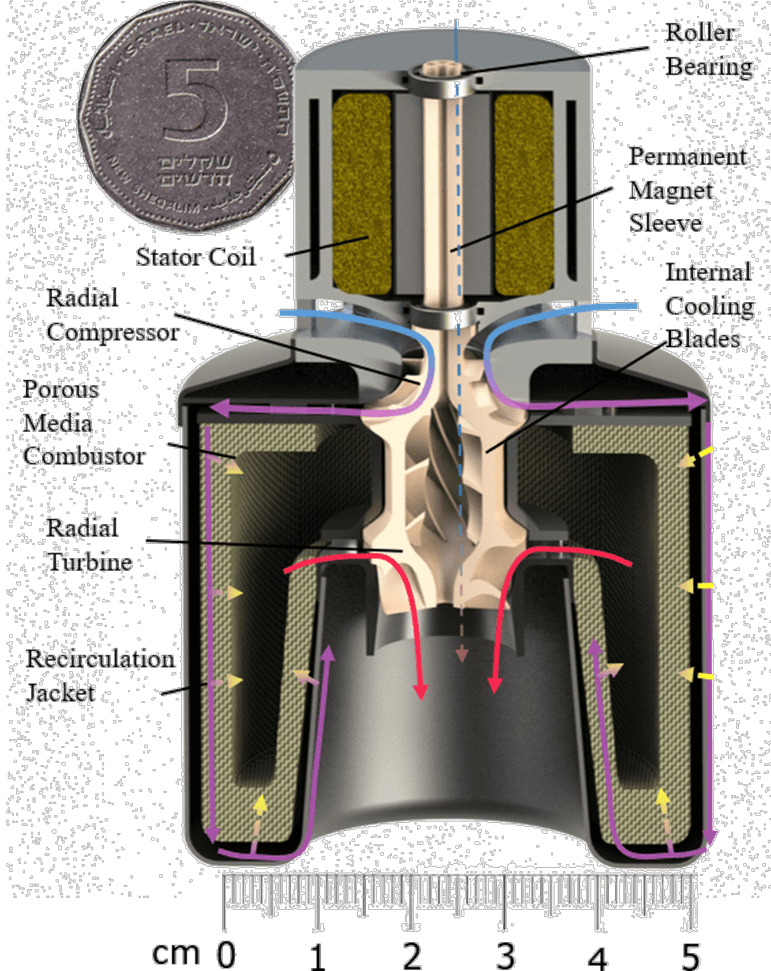

At the heart of their research are micro gas turbines designed for proportional electricity generation. Cukurel defines micro gas turbines as systems capable of generating electricity below 300 kW and thrust below two kN. Taking the AM approach, the team began their first project, a 5cm micro gas turbine that could potentially provide 300W for a drone. The microturbine offers a significant increase in flight time due to its higher energy density compared to conventional batteries.

The team didn't stop at the micro gas turbine; they further utilized their AM knowledge during the COVID-19 crisis. They innovated a pre-assembled, self-supporting turbomachinery design for medical ventilators. "We have transferred this know-how that we developed in pre-assembled self-supporting turbomachinery architectures to gas turbines," Cukurel said.

The breakthrough offered by these pre-assembled, self-supporting micro gas turbines depends on their on-demand availability and cost effectiveness. The primary cost is limited to machine time and energy consumption, which greatly reduces production costs.

Cukurel acknowledged that such groundbreaking work was only possible thanks to the fruitful collaboration with the von Karman Institute for Fluid Dynamics, Izmir Katip Celebi University and PTC. The NATO-funded project saw each country bring its unique expertise to the table. The Von Karman Institute provided high-quality aerodynamics and combustion simulation, Izmir Katip Celebi University provided its computational fluid dynamics skills to evaluate the load-carrying capacity of hydrostatic bearings, and PTC offered its extensive knowledge of AM technologies, particularly through its powerful CAD software for design and simulation, Creo.

Optimizing productivity with additive manufacturing

Addressing design limitations for additive manufacturing, Cukurel explains that they began by developing a "reduced order" model. In simple terms, it is an optimized model that maintains the key aspects of the original system, but simplifies it for easier analysis and use.

In the design of a jet engine, aerodynamics has traditionally taken center stage. The goal is to achieve peak performance in terms of thermodynamics, translated into thrust-to-weight ratio and specific fuel consumption, or in other words power and energy density. However, this approach fails when it comes to miniature engines.

"What we have created are reduced order models that cover all the disciplines present in the engine. These include aerodynamics, heat transfer, rotor dynamics and combustion, among others,” Cukurel explains. Think of it as condensing a symphony into a solo performance—you have to maintain the essence of the piece while also accommodating the capabilities of the solo performer.

He goes on to detail how they created a multidisciplinary optimization environment that knows a priori all the limitations of additive manufacturing. This basically means that they have designed a system that from the very beginning understands the limits of what it can create. It is like an experienced architect who knows not to design a roof with angles too steep for the building materials to support it.

They have ensured that each layer built up during the manufacturing process is self-supporting while obeying the constraints of additive manufacturing, which include considerations of cantilever angles, minimum thicknesses and porosity.

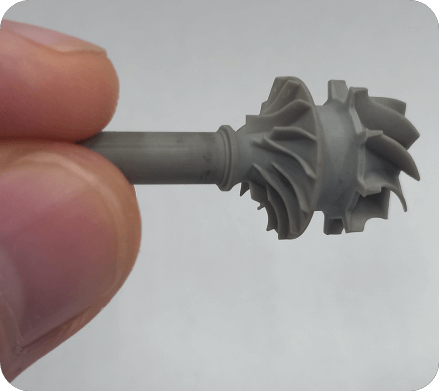

When asked about the material used in the component in question, Cukurel confirms that it is a metal part printed with the EOS M 290. "We also use Lithoz for all of our ceramic production," he adds. Lithoz is a ceramics company that Cukurel speaks highly of, saying they have been "very supportive and enthusiastic about this unique application of the technology."

Ceramic components, although more difficult to manufacture, offer advantages such as smaller defect sizes and smoother coatings, resulting in improved aerodynamic performance. This performance translates into significant fuel savings, hence the potential appeal of using ceramics for specific components.

Cukurel concludes by stressing the importance of meeting the concept design goal, noting that a deviation of at least 5% can affect fuel economy or thrust by nearly the same margin. In the world of jet engine design, even the smallest percentages can make big changes. The supercharger efficiency of the ceramic parts was aerodynamically somewhere between three to four percentage points higher, "I know it sounds small, but you know people are sacrificing their firstborn for the 1% performance difference," Cukurel said.

Is the future of energy 3D printed?

The future of energy could be reinvented by Israeli researchers and their work on pre-assembled engines using 3D printing technology. Their project, focused on the application of micro-gas turbines in distributed energy generation, shakes up conventional understandings of energy efficiency and creates new opportunities for sustainability.

Cukurel proposed two different applications for the technology. First, he highlighted military use, specifically unmanned aerial systems. In this area, supply chain disruption is a serious concern, potentially leaving critical operations without essential components such as bearings for six to nine months. Pre-assembled engine technology circumvents this problem by completely eliminating the need for such a supply chain.

The second and perhaps more fascinating application is distributed power generation. Conventional centralized power plants have an upper energy efficiency limit of about 65%, which means that 35% of the energy generated simply goes to waste. Cukurel proposed a solution using combined heat and power with distributed micro gas turbines in populated areas.

He further explained, “Renewables are intermittent sources. You don't want to bet on whether it's going to be windy today, do you? Or it will be sunny today. You want to run your factory no matter what. So how then do you have a flexible, stable grid even when your renewables may or may not be producing?”

Agile in this context does not mean sprinting around a track. It refers to the ability to quickly adapt and respond to changes in energy demand. In this case, these changes are the unpredictable results of renewable energy sources. Traditional centralized power plants aren't exactly Usain Bolt in this race – they're not built for quick changes. However, small micro gas turbines are.

While the transformative potential of this technology is clear, the main hurdle is return on investment. As it stands, the cost of these micro gas turbines is too high to provide a satisfactory return on investment in a reasonable time frame. Still, the technology discussed here offers a potential breakthrough by dramatically reducing the associated costs.

Additionally, these researchers have plans to commercialize their work. A spin-off from the Technion is pending and partnerships with industry players and strategic investors are in the pipeline. Cukurel expressed his excitement at the potential societal impact of their work, particularly in enabling micro gas turbines to burn ammonia, which can act as a renewable, environmentally friendly, carbon-free fuel. He heatedly explained, “Forget all that business I mentioned to you. Well, just being able to have a micro gas turbine that burns ammonia is a breakthrough in terms of sustainability."

Ammonia has been used as a fuel before, notably during World War II in Belgium, but the design of gas turbine combustors has changed significantly since then. The technology that Cukurel and his team have developed – a porous medium burner – is particularly suited to burning ammonia. Although they did not invent the porous media combustion chamber, they were the first to apply it to this landscape.

Once my curiosity was sufficiently piqued, I delved further into the mechanics of ammonia combustion.

Sustainable energy using ammonia engines

Wartime ammonia-powered engines presented a number of challenges, chiefly their sensitivity to fuel and general lack of flexibility. That's why Cukurel and his team found gas turbines a more suitable technology for their project.

“With gas turbines,” Cukurel explained, “most combustion chamber designs use a completely different technology. They optimize for vaporization, then they have these discharge tubes to meter the fuel and get the hot gases into the turbine. What sets the Technion team apart is their unique application of a specific technology – the porous medium combustion chamber. This is the first time it has been applied to micro gas turbines burning ammonia, making their operation groundbreaking.

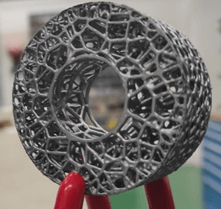

Let's demystify the term "porous media combustion chamber". It is a special type of combustion chamber where the fuel-air mixture is burned in a porous medium, creating highly efficient combustion with low emissions. This is nothing new; has been around for at least 50 years, with traditional manufacturing methods involving dipping foams into a ceramic slurry and then sintering them. However, as Cukurel points out, this gives you "no control over the porosity and how it's distributed in the direction of flow."

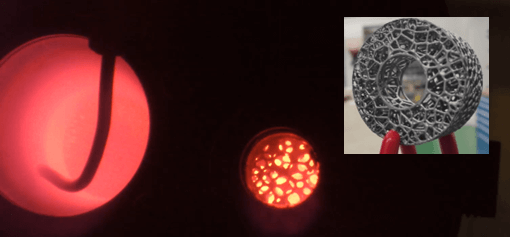

The breakthrough lies in the application of additive manufacturing. I was lucky enough to observe one of these burners and what caught my attention was the donut shape with an organic bubble-like lattice structure inside. The porosity of this structure changes in the direction of flow, which in this case is radially inward. This is where 3D printing comes in handy, as it allows for control of the porosity gradient, which is impossible to achieve with traditional manufacturing techniques.

Cukurel also co-authored a recent paper providing a comprehensive analysis of the design, fabrication, assembly and high-speed testing of monolithic rotors using lithography-based ceramic manufacturing (LCM) and selective laser melting (SLM) techniques. Titled "Ceramic and Metal Additive Manufacturing of Monolithic Sialon and Inconel Rotors and Comparison of Aerodynamic Performance for 300 W Microturbines," this is the first study to directly compare microturbomachinery components made with these methods using aerodynamic and diagnostics for production quality assurance. The paper examines the aerodynamic implications of strutless compressor and turbine design, formulates detailed manufacturing considerations and process parameters for both LCM and SLM, and conducts part quality analysis via surface and CT scans as well as SEM micrography. The results reveal that LCM rotors exhibit higher geometric detail, better surface finish, less manufacturing-related surface artifacts, and lower porosity compared to SLM rotors.

These innovative concepts and future applications could change the world as we know it. As we face the existential threat of climate change, innovations like these aren't just intriguing; they may be critical to our survival.

0 Comments