One less talked about area where we've seen 3D printing grow in recent years is the packaging industry. With a market valued at $1.21 billion in 2023 and expected to grow to $2.56 billion by 2023, according to Future Market Insights, recent years have seen more and more big names including L'Oréal and Pepsi , who turn to additive manufacturing. Now we have another one to add to the list, Unilever, who turned to 3D resin printing from Formlabs, to make molds for plastic bottles.

You may not have heard of Unilever before. However, you've definitely heard of some of the British company's products and brands, including Axe, Ben & Jerry's, Dove and Knorr, among many others. The fast-moving consumer goods (FMCG) conglomerate is the world's largest soap manufacturer, with products available in over 190 countries. Still, the FMCG sector is fiercely competitive, and as such Unilever is constantly looking for ways to innovate, including this latest move to use 3D printing for bottles.

Comparing bottle prototypes made using a 3D printed mold

Stefano Cademartiri, Owner of CAD & Prototyping, Unilever, adds: “A consumer goods company like Unilever needs to be in the market as soon as possible or before your competitors. You need to offer consumers the best product at the best price in the shortest possible time. 3D printing helps us speed up this process.”

How is Unilever using 3D printing to produce bottles?

Traditionally, making a simple plastic bottle takes a lot more time than you would expect. From design to finished product, including making molds before moving to blow molding, often takes months. Also, there is little opportunity to try out different prototypes and designs due to the time it takes to create just one mold, which is estimated to be around 6–8 weeks.

By integrating 3D printing into the process, this is dramatically reduced, as a 3D printed mold can be completed in just two days, resulting in pilot testing in just two weeks, while costing significantly less. Flavio Migliarelli, R&D Design Manager, Serioplast Global Services, further explains: “With the 3D printed mold, we can save up to 70% of time and 90% of cost compared to the standard mold. In the past [customers] had to wait up to 12 weeks for just one design, now we can do five designs.”

As should be clear, 3D printing in this case is used alongside more traditional methods. Specifically, the shapes are created using a 3D printer Form 3L from Formlabs and Rigid 10K Resin, which allows for precise shapes with a smooth surface while being able to withstand internal pressure and temperature. Using SLA also helped Unilever integrate more detail into the bottles, with logos and other fine details coming out well.

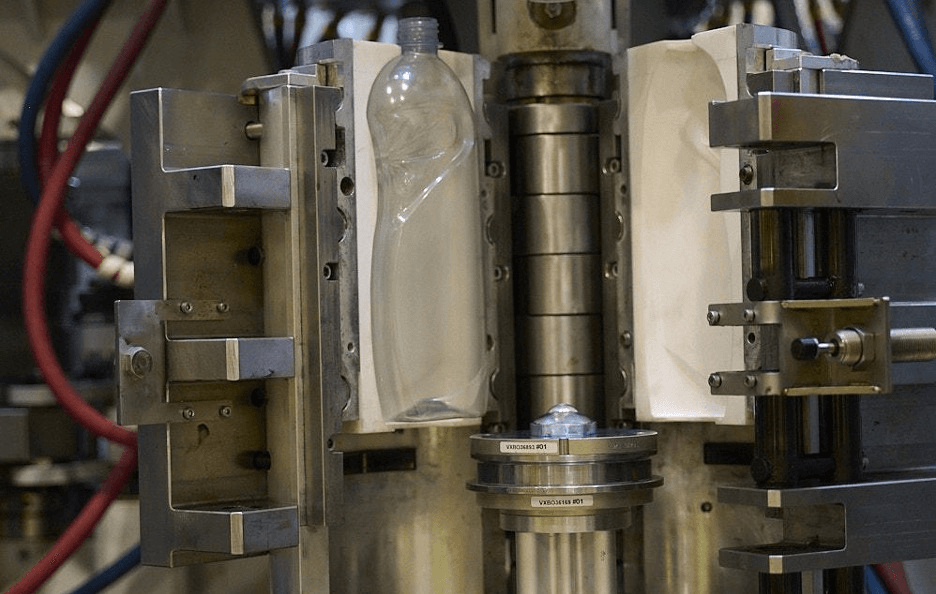

The 3D printed mold is attached to a metal apparatus and can then be used together to create plastic bottles

After the mold is created, the bottles can be made by blow molding, in this case stretch blow molding (SBM), which is commonly used to create high-quality, glass-clear PET containers. Applications for a combination of these technologies include testing aspects of the production line at an early stage thanks to the similarity of the bottles to the final product, validating the SBM process and the PET preform, and accelerating prototyping.

You can also find Formlabs printers and materials here. File the link for easier:

https://shop.3mgbonev.com/category/3d-printeri-formlabs

*All photos: Formlabs

0 Comments