Enhance your CNC machine shop capabilities by integrating 3D printing to take advantage of rapid prototyping, reduce waste and offer customers more design flexibility.

The contrasting manufacturing methods of 3D printing and CNC machining are often thought to be in direct competition when it comes to making solid parts. But actually these opposites attract. Mostly, when used in the same team, the strengths of one process complement the limitations of the other.

Just look at the majority of 3D printing services today that also offer CNC machining. From Craftcloud to Xometry to Hubs, these services know that sometimes 3D printed parts require some CNC machining to achieve tighter tolerances, better surface finish, or simply add holes to drill. In other cases, a customer may have different CNC machining needs and 3D printing needs in their manufacturing process, or they may not know which technology is most appropriate.

CNC shops can join this growing maker market by including their own 3D printing services.

For example, RPG Industries , a precision manufacturing shop in Tipp City, Ohio, incorporated Markforged's metal and carbon-fiber-reinforced nylon 3D printers into its offerings for both rapid prototyping and final metal parts in geometries that would be too overwhelming on CNC costs, says Bob Gingsberg, president and founder of RPG Industries. "Composite and metal 3D printing is really going to be the future in our industry, and we want to be the first to implement it and the experts in the field."

3D printers are also welcome in in-house company machine shops. Nikola Corporation, the American manufacturer of commercial battery electric vehicles, CNC machines complex aluminum parts, but engages a large-scale 3D printer from BigRep to make the unique fixtures to hold these parts while they are machined.

In this article, we take a detailed look at ten reasons why you should add a 3D printer (or several) to your CNC shop and introduce some manufacturers who have found success offering the two technologies side by side.

Faster, cheaper prototypes

As any manufacturing business owner will tell you, time, cost and how to reduce both are always at the forefront of their minds. Design iteration is a part of the manufacturing process that consistently takes longer than expected and creates all the problems that delays can cause.

Using 3D printing to prototype tools or parts in just hours becomes an essential step before committing to full-scale CNC machining. This helps to optimize toolpaths, identify potential problems and improve the manufacturing process.

Rapid prototyping with 3D printing can take days off a project. For example, RPG Industries was tasked with recreating a discontinued engine part for a classic car. Their first step was to 3D print the part in durable carbon fiber nylon to test whether it fit into the assembly. "We can significantly reduce the delivery time," says Gingsberg. "We can print at night, the lights go out without human intervention."

The time saved, ease of use and added ability to make digital design revisions on the go are transformative for engineering shops.

Extended offers

Adding 3D printing services to your current CNC machining offerings simply expands the scope of potential work and customers for your shop. Some customers' needs are better suited to 3D printing technology, or they may need both for different stages of the product development process, such as a functional prototype 3D printed for approval before the final part is CNC machined.

In3DTech , a large contract manufacturing shop in Shanghai, says its CNC machining and injection molding capabilities complement its metal and polymer 3D printing service, making it "a great one-stop shop for your advanced designs." 3D printing offers customers more manufacturing flexibility, no expensive tooling is required, there is more geometric design freedom and parts can be printed quickly on demand, the company says.

The machine shop at the Geophysical Institute of the Univ, of Alaska Fairbanks recently added a metal 3D printer from Markforged to create specialized research tools and components for scientists. "Being able to do metal stamping greatly expands what we can do," says Greg Shipman, machine shop manager at the Geophysical Institute. "One of the great advantages of 3D printing is that you can achieve geometry that would be almost impossible to do with machines."

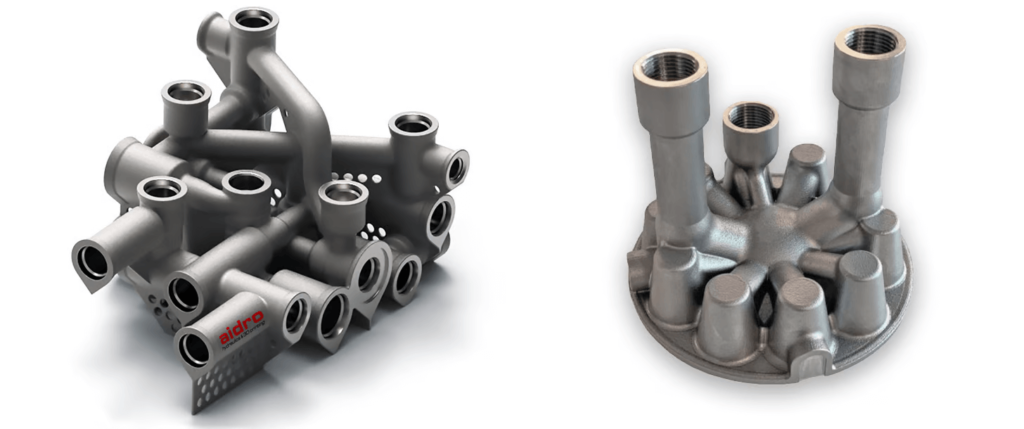

Complex designs

Some parts are extremely difficult or impossible to CNC machine, such as parts with complex internal grooves. 3D printing can step in to offer customers a solution when CNC machining can't handle the task. For example, creating injection molding molds and cores with internal cooling channels, or the ability to make a part less heavy by using a filler mold instead of solid material.

Because 3D printing enables designs not possible with a CNC machine, manufacturing shops can offer customers more innovation. Engineering challenges can be approached more flexibly. For example, multi-component assemblies can be reengineered for 3D printing to contain fewer parts and thus be easier and cheaper to manufacture, as well as incorporate new efficiencies.

Faster batch customization

3D printing is not inherently faster than CNC machining because the speed of batch production depends on several factors, including the complexity of the part and its size and material, but when it comes to a batch of products where they are all customized or slightly different, 3D printing is the better choice.

With 3D printing, there are no minimum order numbers, as can be the case with technologies that require unique tools or molds. It lends itself to the rapid production of small quantities of parts that can be easily customized, making the process ideal for niche markets, flexible volumes or special designs.

For example, at Volkswagen Autoeuropa, the in-house machine shop used to outsource special assembly tools for its production line to a third party until it installed UltiMaker 3D printers. With the ability to quickly make batches of unique designs, the company was able to streamline a process that used to take 35 days for a new design iteration to just four days, with a dramatic cost savings of 91%, or more than $325,000 per year.

Taking full control of the complete design process means that each new tool is now cheaper than the $10, and the team can continuously improve each version internally as and when needed, the company says.

Increased resistance

Sustainability is a huge concern for companies and manufacturers alike, both in response to modern consumer attitudes and the legacy of waste in the machinery industry.

3D printers can be an environmentally friendly addition to your machine shop. They produce very little waste and usually don't require as much energy to operate as other shop tools, depending on the technology. In addition, they can use bio-based filament and 100% recycled. Some can even print with shredded plastic waste from your workshop.

Workplace organizers

If not only as a proposition for customers, the 3D printer is a great tool for creating products for your workshop. Every workshop is different with unique needs when it comes to organizing aids and accessories.

In a manufacturing environment, the way tools are stored and equipment is arranged has a large effect on the movement required of workers. The closer the tools are and the better organized they are, the less time the worker spends accessing, or worse, searching for the right tools.

Many workshops are already using 3D printing to make custom designed and built bins, racks and other tool holders. Organizers for drawers, cabinets and other storage items can also be custom made to improve the efficiency and effectiveness of processes in your workspaces. In addition to these organizing aids, your 3D printer can produce any number of custom consumables or machine components. This reduces dependence on external suppliers and enables quick replacements.

Custom widgets

One of the primary ways 3D printers are used in existing CNC machining operations is to create custom tools, fixtures, and fixtures used in CNC processes. This can relieve time, cost and labor-intensive machine asset pressures while improving the precision and efficiency of the CNC processes themselves, especially for unique or specialized projects.

PHB Machining & Molding in Fairview, Pennsylvania, says the most practical benefit of 3D printing in their shop is the way it can reduce fixture and tooling costs. "It also saves our team time when we have to program additional processing equipment because CAD files can be imported directly into a 3D printer," the company says. "3D printing is suitable in many scenarios, such as when you are looking to save costs, incorporate features that machining cannot produce, or simply want to hold a low-precision part in your hand."

Economy of materials

3D printing builds parts from scratch, depositing the necessary material only where it is needed, helping to minimize waste.

In contrast, CNC machining is a subtractive process generating a significant amount of waste material.

Adding a 3D printer to your workshop can help save materials in two ways.

First, by 3D printing accurate prototypes for assembly and functional testing, you can be sure that your final CNC-machined design will fit perfectly—and require no additional iterations.

The second One way 3D printing can save you and your customers on material costs is that 3D printers use less material in the first place.

3D printing in expensive materials like titanium requires fewer raw materials and produces less waste material.

You also have the option to change the part design to consolidate parts or create a grid fill instead of solid material, both ways to create a part using less material.

Functional prototyping

Although some 3D printing technologies are suitable for prototyping, other 3D printing technologies can produce functional prototypes in a wide range of engineering materials, including plastics, metals and composites.

This type of prototype provides customers with the ability to conduct physical testing during the development phase, which is particularly useful when exploring material options.

One company operating in this space and offering the benefits of prototyping materials to customers as early samples that test product concepts and feasibility is Philadelphia-based Product Development Factory (PDFact). "Testing product functionality and durability under certain environmental conditions leads to new iterations and improved designs," the company says. "3D printing introduces a major advantage as parts can be created and integrated into pre-existing systems even when the original parts are not available."

PDFact offers in-house 5-axis machining capabilities and a variety of 3D printing technologies to offer customers prototyping and proof-of-concept assembly and inspection equipment. The company uses functional prototypes for physical testing, mechanical characterization, and testing of systems and components.

Easy to work with

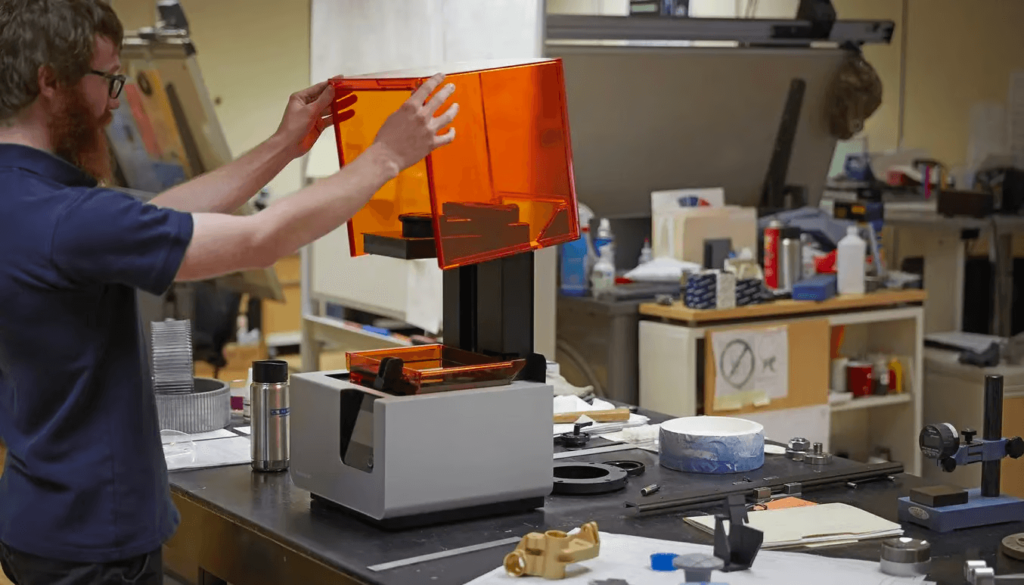

A universally recognized advantage of 3D printers is their ease of use. Unlike CNC machines and other specialized equipment that may be required in a machine shop, most 3D printers do not require specialized training to operate and would be relatively easy for highly skilled and experienced engineers.

That was the case at A&M Tool and Design, a Massachusetts-based machine shop that's been in business for more than 65 years, when they brought desktop 3D printers from Formlabs to retrofit. "3D printing has become an invaluable tool in our toolbox," said Guido Jacques, vice president of operations at A&M. "It's kind of a cliché, but it really allows us all to think completely outside the box."

Initially, the company added a Formlabs resin 3D printer to accelerate projects and open up capacity to supplement an understaffed engineering team, and then scaled 3D printing applications from prototyping and communication models to high-speed manufacturing tools and final parts. for consumer machines.

0 Comments