Depending on the materials used, 3D printed buildings offer numerous advantages over conventional construction, including fire resistance, local or recyclable

materials, lower overall costs and, of course, shorter construction times to accommodate population growth in a more timely manner.

At the American University in Cairo (AUC), researchers have been hard at work developing their own additive manufacturing-based building system that prioritizes local building materials, robotic manufacturing and a strong push towards zero-carbon manufacturing.

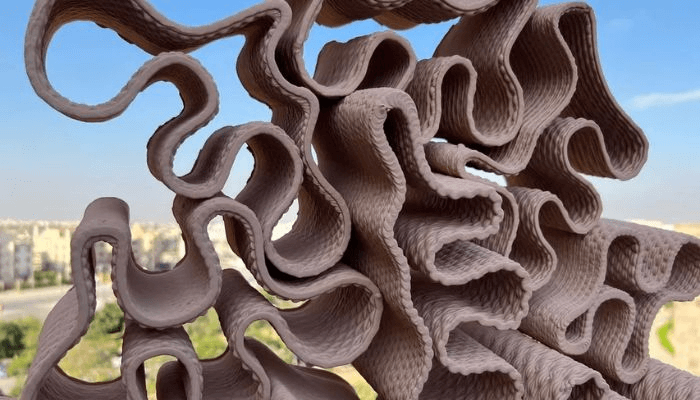

The result? The success of their 3D printed clay brick project is the first of its kind for North Africa and provides insight into the potential in the region.

The researchers are in one of only three laboratories currently experimenting with clay bricks in Africa and the Middle East.

Specifically, the metal and clay-based additive manufacturing method was developed through a collaboration between AUC's Centennial Additive Manufacturing Laboratory (AMCL) and the Robotic Fabrication Laboratory (RFL).

This process is able to use robotic arms to build complex structures at a fraction of the energy, time and emissions cost of traditional construction practices.

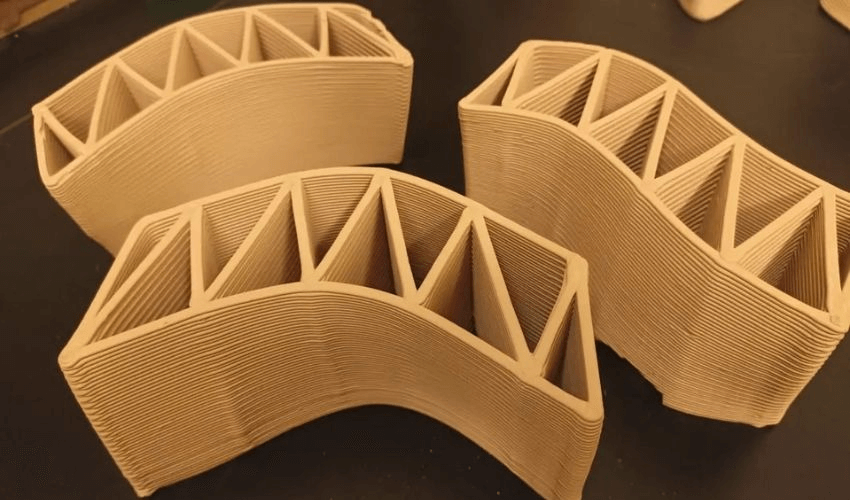

Avoiding concrete mixes typically used for AM construction projects, the team chose what they call a specialized red refractory clay that is more durable and heat-resistant than normal clay due to its composition, which includes minerals such as feldspar, quartz and kaolin.

The mixture can then be easily extruded into the desired shapes using the team's large-scale robotic 3D printer.

The use of clay plays a crucial role in the team's vision and commitment to sustainability. Based in Egypt, the team is aware that clay (and clay-making material) is in abundance, as traditionally produced clay bricks have been used in the region since time immemorial. The result for the AUC team is a constant supply of local materials to work with as needed. Indeed, the positive impacts were highlighted by the team, who predicted that the technology would help boost the local economy while providing easy and more affordable housing for those in need.

“AM will actually integrate with traditional manufacturing to complement it rather than replace it. With AM, there is the freedom to design, inspire innovation and positively impact society in an environmentally friendly way, as well as reduce the drain of [foreign] currency. It will also provide companies with the means to limit outsourcing to third parties by developing concepts in-house and create an advantage over competitors by shortening the product development cycle,” explains Professor Hanadi Salem, Chair of AUC's Department of Mechanical Engineering.

More value, less waste with 3D printed clay

Visually pleasing and capable of being shaped into curves and more complex geometric patterns, this red fireclay has several advantages that make it an ideal green building material, especially when combined with additive manufacturing. As RFL Director Professor Sherif Abdelmohsen explains, “It is much more efficient in brick production compared to traditional methods as it eliminates the need for manual molding and firing. It also generates less waste as any unused or leftover material can be easily recycled and reused. This allows greater control over the manufacturing process, resulting in bricks of consistent quality, strength and durability.”

Their works were displayed at COP27 and during that time highlighted the unique design and potential of this building material.

0 Comments