Carbon fiber is one of the most powerful materials for anyone trying to get the most out of 3D printing.

But when should you use it and what applications can you use it for?

Let's delve into these questions and discover why 3D printed carbon fiber composites are more affordable and versatile than ever.

Understanding Carbon Fiber Composites

Carbon fiber has a rich history dating back to its use by Thomas Edison as the filament in light bulbs in the late 19th century. Recognizing the power of carbon fiber, Union Carbide Corporation further developed its processing techniques in the 1950s. Fast forward to the present and carbon fiber is now commonly used in high-stress products such as race cars and aircraft. With the advent of 3D printing technology and recent advances in composite techniques, carbon fiber is now available for a whole range of new applications.

The benefits of carbon fiber 3D printing

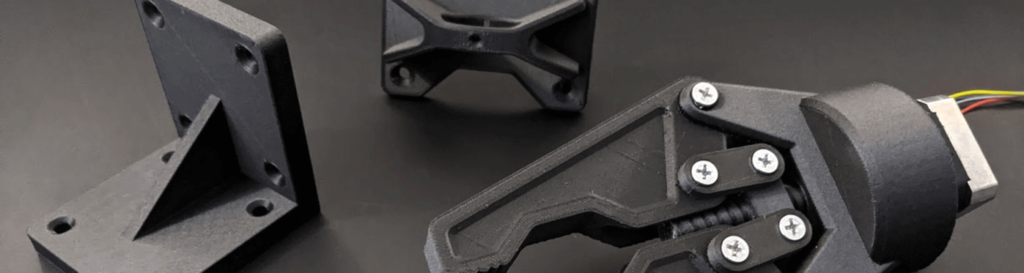

Traditional carbon fiber is known to be strong, lightweight and has a distinctive visual appeal with its graphite black cross weave. However, traditional manufacturing processes can be labor-intensive and expensive. This is where carbon fiber composites come into play.

By combining chopped carbon fibers with a base resin or polymer, the resulting composite is more manageable. This makes it suitable for a variety of manufacturing techniques, including 3D printing. Furthermore, the introduction of different base polymers can add unique properties, improving the flexibility of carbon fiber composites.

The right time to use 3D printing

Before diving into finding your ideal 3D printing application, it's critical to understand when it's most useful. Consider factors such as time savings, cost per volume, and the specific material properties required for your applications.

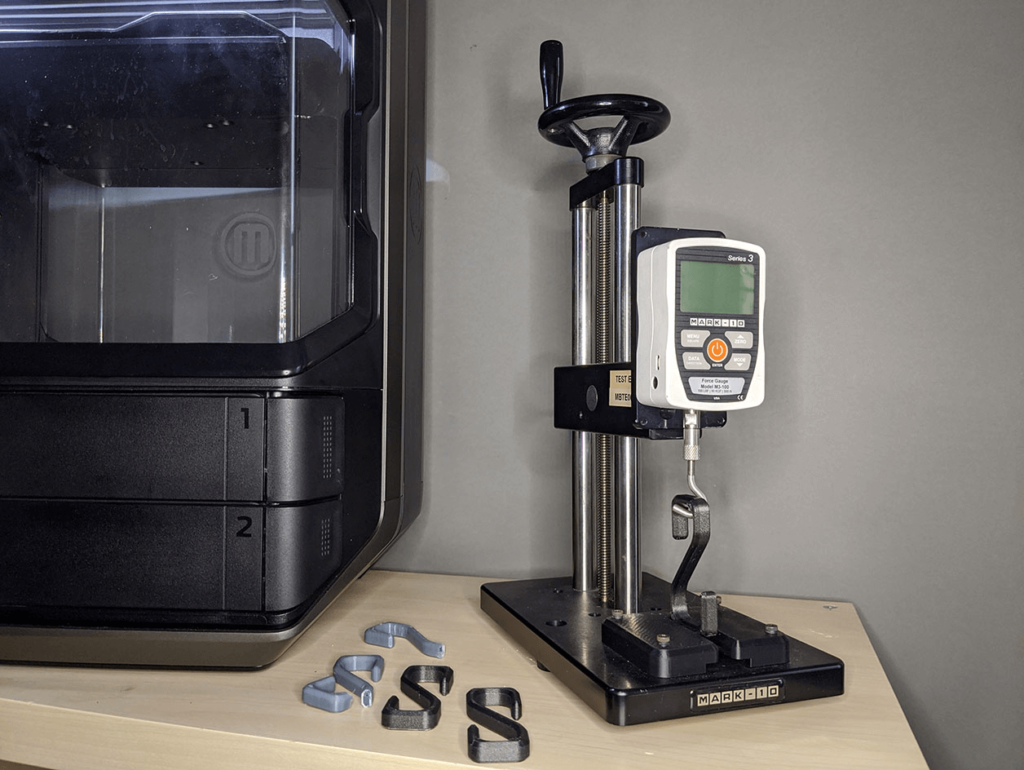

Save time with design iterations

One of the most significant advantages of 3D printing is the ease and speed of setup. It allows a direct transition from design to print job, greatly reducing the labor of creating individual parts. This advantage is further amplified when the part goes through multiple design iterations.

Cost effectiveness based on volume

For high-volume production, traditional manufacturing methods such as injection molding may be more cost-effective due to economies of scale. However, for low-volume requirements such as prototypes, custom tooling or spare parts, 3D printing often provides a more economical solution.

Meets requirements for material properties

When selecting a material and manufacturing process, understanding the specific requirements of your application is paramount. You'll need to consider the voltages, temperature thresholds, and exposure to moisture or chemicals your part will endure. Carbon fiber composites often meet or exceed the requirements of high-performance parts, making them a viable alternative to traditional metal components.

Using the power of 3D printed carbon fiber composites, you can revolutionize your manufacturing process and create high performance custom parts with ease and efficiency.

0 Comments