Although the focus is often on engine power and exterior design when talking about cars, there's another automotive feature that's ripe for innovation. The car seat, which functions as an interface between the driver and the car, is one of the most important elements of the car and must offer ergonomic support, safety and comfort features.

Recent years have seen an increasing focus on how to reinvent and improve car seats using new design concepts and advanced manufacturing such as 3D printing. One such project, titled "Concept Breathe," is the result of a collaboration between students from Braunschweig University of the Arts, German car manufacturer Audi, and large-format 3D printing specialist BigRep.

A multi-partner effort

The Breathe concept, culminating in the creation of a "breathable" seat for a full-size car, was born from research into the car of the future. Design students at Braunschweig, led by Dr. Manuel Kretzer, professor of materials and technology, and Audi's development/innovation department, led by Mike Herbig, were inspired by the idea that the car of the future could have a larger connection with a driver. As the saying goes: "What if it becomes a partner that reacts and responds to our actions, an organism, a friend that lives and breathes?"

Interestingly, Audi has already started to pursue this idea with the development of the Klara, a "sensitive Audi A1" in 2017. This concept study aimed to foster greater empathy between the car and the driver by creating a sensitive car that seems to breathe . The breathing effect is the result of 39 electric motors mounted under the metal structure of the car and several sensors that would allow Klara to take in air and react to its surroundings.

The Concept Breathe car seat project, undertaken in the spring of 2017, was a continuation of the Klara experimental initiative, which sought to combine different technologies and design principles to create a more human car seat that could dynamically moves with the driver.

"What if the seat becomes a partner that reacts and responds to our actions, an organism, a friend that lives and breathes?"

Concept Breathe Concept

The "sit" project was led by a group of 10 undergraduate students at the Braunschweig University of the Arts as part of their digital fabrication module. The courses in this module are specifically aimed at developing an 'experimental understanding of emerging design possibilities' through the use of innovative algorithmic and parametric design principles, as well as digital manufacturing technologies such as 3D printing that bring design concepts to life.

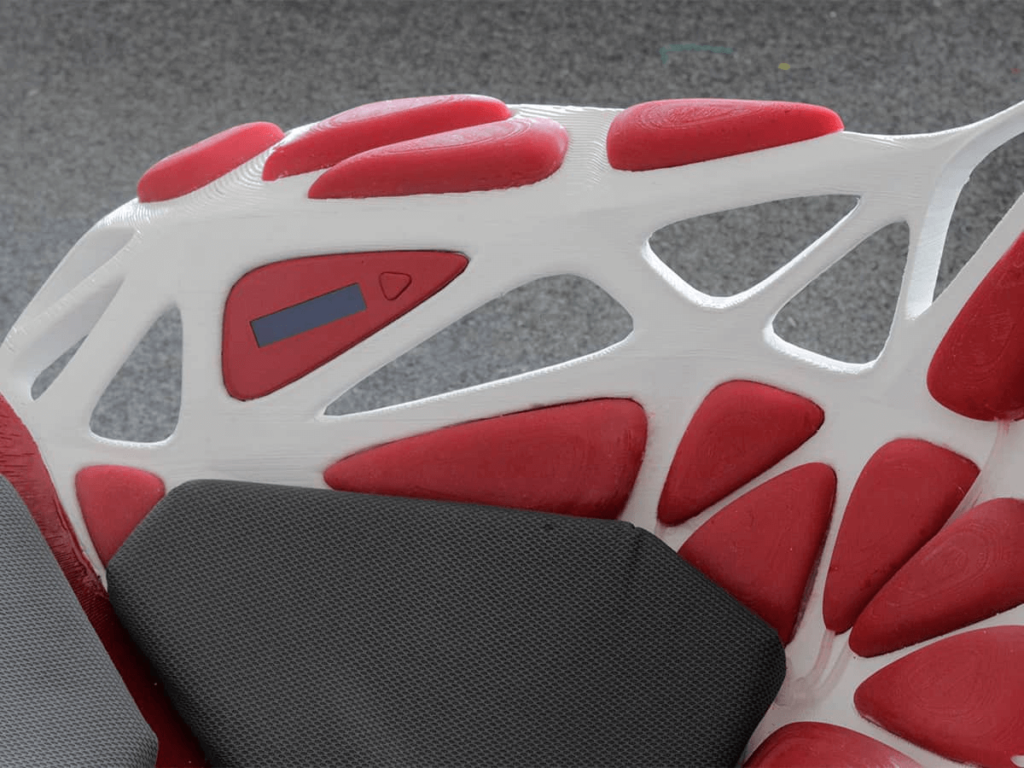

Ultimately, the car seat design is inspired by organic forms and systems and consists of several active components integrated into a lightweight frame. Due to the complex geometry of the final design – which was the result of several parametric design iterations – the student team and their partners decided to 3D print the seat prototype 1:1. BigRep, known for its large-scale 3D printers, did a more than excellent job.

The seat structure was 3D printed using the BigRep ONE machine, which has a large build volume of up to one cubic meter, and BigRep's PRO HT filament, an easy-to-print biopolymer with increased temperature resistance compared to traditional PLA. The printing process took almost 10 days to complete, marking BigRep's longest print run at the time.

Attached to the 3D printed frame were 38 custom active components that created a haptic and visual breathing effect, along with a range of specially designed cushions made from high performance textiles for optimized comfort and support . As the design team put it: the active components (seen in red) "are designed to increase the seat's ability to respond to changing driving conditions, but especially to improve the user's identification with the animated object through breathing movements."

Paving the way for innovation

BigRep's 3D printing technology was vital to the realization of the project. Not only was the company's large-format 3D printer equipped to handle the scale of a full-size car seat structure (reducing the need for post-print assembly), it was also able to reproduce the complex organic shape of the product. What's more, 3D printing offered project partners a cost-effective way to directly create a large prototype without having to invest in tooling or turn to complex supply chains.

In the same way that large format 3D printing was critical to the realization of this concept design, the technology is now being used throughout the automotive industry to explore new design ideas and bring new innovative solutions to market, from rapid prototypes to end-use parts . In automotive seat applications in particular, there are a number of projects that utilize the technology's ability to create complex designs optimized for performance and comfort, as well as customized products at scale.

Similarly, German automaker Porsche recently released a 3D-printed "full-bucket seat" that integrates custom 3D-printed grilles for superior support and breathability. Like the Concept Breathe, the 3D printed seat emphasizes the relationship between humans and technology to generate an enhanced driving experience, especially for high-performance vehicles.

3D printing is the future of automotive

After all, the Concept Breathe project would not have been possible without additive manufacturing, especially BigRep's large-format 3D printing. Technology has proven to be essential for the rapid and cost-effective realization of an innovative idea.

For the wider automotive industry, the ability to 3D print large structures and products in a single part has huge advantages. On the one hand, it enables design consolidation, allowing large structures to be printed at once, minimizing assembly and post-processing time. This has a significant impact on time and cost, whether users are printing a design concept, a functional prototype, or an end-use part.

Technology also enables product designers to create previously impossible designs, opening up limitless opportunities for innovation. With it, forward-thinking individuals and teams (like the Braunschweig design students and their partners at Audi and BigRep) can really dive into new ideas and transform them into something real, something that can shape the future.

To learn more about how 3D printing helped bring Concept Breathe to life, watch the following video:

0 Comments