3D printing technology makes functional, beautiful product prototypes accessible to everyone. Learn how to get started now.

If you've ever tried to pitch a great idea for a new product or invention, you know that your passionate description just isn't enough. A detailed sketch or video is better, but nothing wins people over like a prototype they can hold in their hands.

Today, 3D printing is the best way to create product prototypes and models, and for good reason. It is faster, cheaper, more accurate, and has better presentation value than "foam carving," clay molding, or any of the manual processes once used to create handmade concept models.

A good prototype gives your product more appeal that is sure to impress your client, boss or investors. Plus, since 3D printing is so easy and affordable, there's no longer an excuse to use tape and glue.

3D printing, whether you do it yourself or use a service, allows you to get your idea to market faster. Depending on your product, you can print a working prototype in a few hours, allowing you to test functionality and aesthetic appeal, redesign and print new iterations the same day.

Here, you'll learn the basics you need to know to 3D print your product prototypes, including which materials to choose, whether it makes sense to buy your own 3D printer (and which one), and how to choose and use on-demand 3D services print' to get your prototype quickly printed and delivered to your door.

Prototypes for product development

Long before you get to the point of presenting your idea, you test whether or not it will actually work. In theory, your product will change the world. First, testing it will show where it needs more work.

3D printing allows you to create great-looking models, but also fully functional, working prototypes strong enough to be tested in real-world conditions. Hands-on testing is the primary step in uncovering the problems you may encounter in manufacturing your product and how customers will use it. Real-life testing and analysis help you bring better products to market.

Many product designers 3D print prototypes of the initial design in basic plastic, then move on to engineered materials or even 3D printed metal for functional testing.

Let's look at some examples.

Full size and functionality

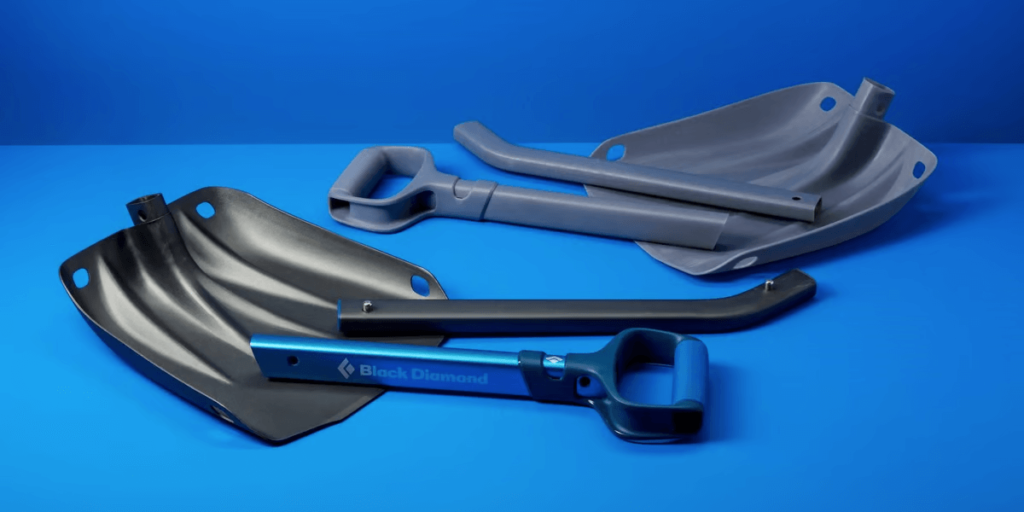

Black Diamond Equipment makes innovative climbing, ski and mountain gear known for comfort, durability and performance. All of their products go through a rigorous design, testing and iteration process before they hit the market.

The company has used 3D printing in its design workflow for years to create prototypes or scale models in-house. Larger full-scale prototypes were often outsourced to a prototyping firm, as the standard size of desktop 3D printers was too small until they discovered Formlabs Form 3L – a stereolithography (SLA) 3D printer with a build volume that can handle human-scale prototyping of products such as helmets and the mountaineering shovel pictured below.

Available iterations

Entrepreneur Khalid Bou-Rabee took a different approach to test whether his new home weight training invention would actually work.

“Computer simulations can be very accurate, but nothing can replace real-world testing. I needed prototypes,” he told All3DP.

At first, the young entrepreneur thought he would order a stainless steel prototype, but quickly changed his mind when he was quoted a price of over $1,000 for a single CNC-machined metal part. He then turned to the 3D printing services marketplace, which provides instant offers. Through this, Bou-Rabee discovered a steel-tough polymer alternative and found a 3D printing partner that could afford to produce multiple iterations, allowing him to test his product and bring it to market within a year.

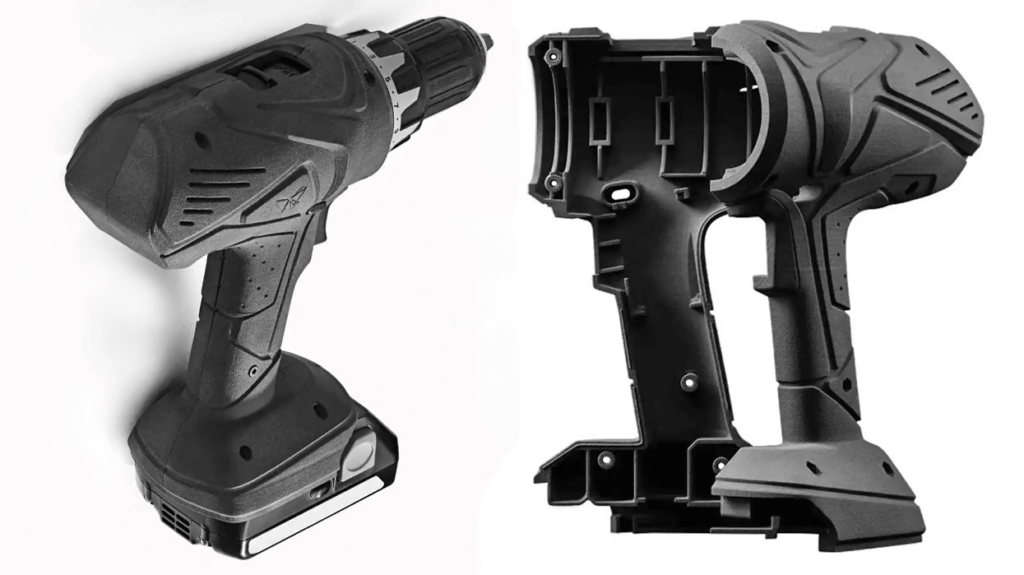

Functional testing often means creating a prototype out of the same material the final product will be made in, such as carbon fiber or stainless steel. With the ability to rapidly 3D print stainless steel parts both in-house and through on-demand services, design teams can produce functional prototypes for testing, such as the 3D printed aluminum bicycle frame from Canyon pictured below.

In another example of metal 3D printed prototyping, Shukla Medical manufactures surgical instruments using 17-4 PH stainless steel on a 3D printer Markforged. Stainless steel is the same material as many of the finished products. These metal instrument prototypes go into the hands of surgeons for evaluation. "The surgeon can visualize using it in the actual incision and can tell us if it feels the right way in their hands," says Zack Sweitzer, the company's product development manager. "Being able to prototype more efficiently and bring finished products to market faster will keep us at the forefront of the industry."

3D printing materials for prototyping

The materials you can 3D print your prototype in are virtually limitless, spanning soft silicones, metals, strong plastics, conductive copper, sustainable wood, and even chocolate. There are thousands of 3D printing materials available and methods for 3D printing with multiple materials at once.

If you are not sure which materials would be best for your prototype, we at 3MG Bonev Ltd. we will help you and explain the different materials, their properties and what they are most often used for. We've linked a few in the materials list below.

Common 3D Printing Materials:

- PLA Plastic

- TPU (flexible)

- Stainless Steel / stainless steel

- Carbon Fiber / Carbon fibers

- Flame Retardant Material

- Nylon / Polyamide

Below we lay out the basics in a quick diagram.

| Vish | Materials | price | 3D printing technology |

| Hard | PLA | Cheap | FDM, SLA |

| Flexible | TPU, resin | Affordable | FDM, SLS |

| Transparent | Resin | Affordable | SLA |

| Durable | Nylon, carbon fiber | Moderate | FDM, SLS |

| Sustainable | Recycled PETG, Recycled PLA | Affordable | FDM |

| Heat resistant | Flame retardant PLA | Affordable | FDM, SLS |

| Soft to the touch | TPU, flexible resin | Moderate | FDM, SLA |

| Colorful | Resin | expensive | Polyjet, inkjet |

Types of 3D printing for prototyping

There are more than a dozen types of 3D printing. All of these are used for rapid prototyping. Finding the perfect match for your product is a matter of balancing cost, speed, material, part complexity, and whether you want to print it yourself or outsource it to a 3D printing studio. In general, the most used prototyping technology in plastics is fused deposition modeling (FDM) because it is the easiest and cheapest.

If you outsource your prototype to a 3D printing studio, you may be asked how you want it printed. Below we cover the basics.

| Must | 3D printing method | price |

| Quick | FDM | Cheap |

| Economical | FDM | Cheap |

| Accurate detail | SLA, SLS | Affordable |

| Metal parts | FDM, SLM | Moderate |

| Multiple parts | SLA, SLS, MJF | Moderate |

Buy a 3D printer or outsource to a 3D printing studio?

Creating internal prototypes

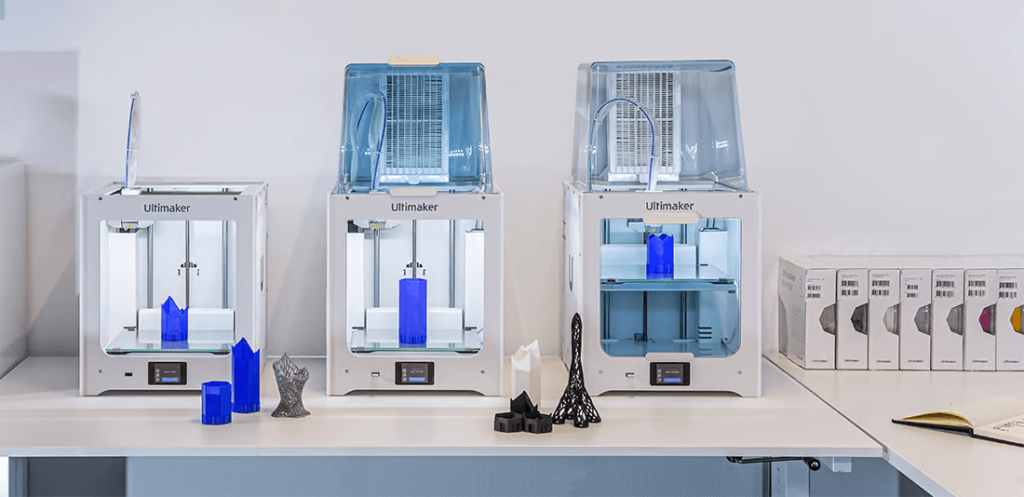

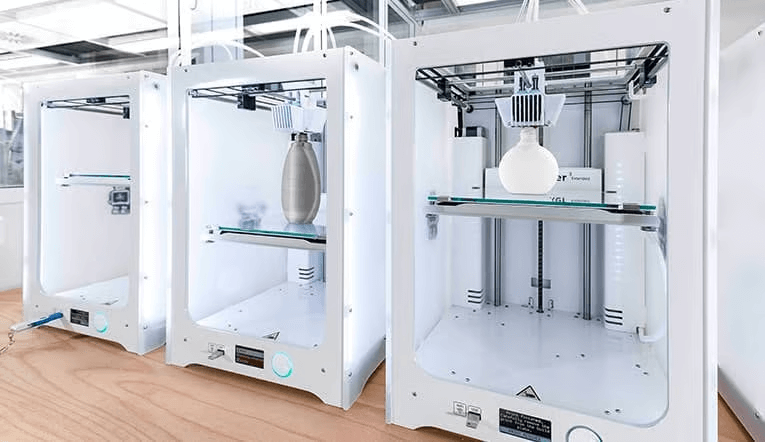

The initial cost of a 3D printer can seem daunting, but depending on how much you prototype, the machine can pay for itself in just a few weeks or months when you compare it to what you would spend on outsourcing or alternative manufacturing methods.

There are hundreds of great 3D printer brands out there. You can start 3D printing yourself with machines practically immediately after taking them out of the box. Also, a good, basic machine can only cost a few hundred dollars.

More sophisticated machines that will print with more durable materials start at around $3000 and can also be very easy to use but require some training which is often provided by your equipment dealer.

Today, companies that frequently create prototypes, such as industrial design firms, have 3D printers in the office as standard equipment.

"At this time in product design, 3D printing has become a tool of the trade," says David Block, director of Studio Redeye in Brooklyn, New York. "If you don't have a 3D printer and you're in the product development space, you're behind," echoes Jonathan Thai, co-founder and partner at HatchDuo in San Francisco.

But which machine should I buy?

3MG Bonev Ltd. is a representative of high-class 3D printers of almost all technologies. So don't hesitate to contact us for advice, purchasing, training, warranty and out-of-warranty service.

Design your prototype for 3D printing

If you have an idea for a prototype product—and lack design skills—you'll need a computer-aided design (CAD) professional to create the digital file needed to print your part.

Designing products and parts for 3D printing is its own skill set.

Unlike designing for other types of manufacturing or virtual environments, it's important to work with a designer who understands the differences between the seven types of 3D printing technologies, the unique materials often available, and the demands of 3D printing.

3D designing in CAD software is not a skill that is easily or quickly acquired.

In fact, there are many pitfalls that even an experienced designer can encounter if they are not familiar with 3D printing.

Part walls that are too thin to print in your chosen material or features that are too small to 3D print with your chosen 3D printing method are just two of the common ways a part fails to print properly.

Even if you approach a professional 3D printing service to print your design, they may determine that it is not suitable for 3D printing.

When you upload your digital design to a professional 3D printing service, many offer a "printability" check of your digital file before printing begins.

But if you fail this check, the services usually don't tell you how to fix your model.

Many of the best 3D printing services offer some type of design service, from basically "fixing" your STL file to working with you to design a new product from scratch.

We from 3MG Bonev Ltd. we can help you with that too.

0 Comments