3D printing non-machinable parts for Hexapods

More than ever, the way we produce is changing. In particular, due to increased issues such as the global supply chain crisis of 2022 or even the COVID-19 pandemic itself, we see the benefits of local production. For this reason, the adoption of additive manufacturing is also growing in many new sectors. One particularly interesting case comes from the French company Symetrie (which translates to symmetry), which acquired a 3D printer from OMNI3D to help produce the hexapods.

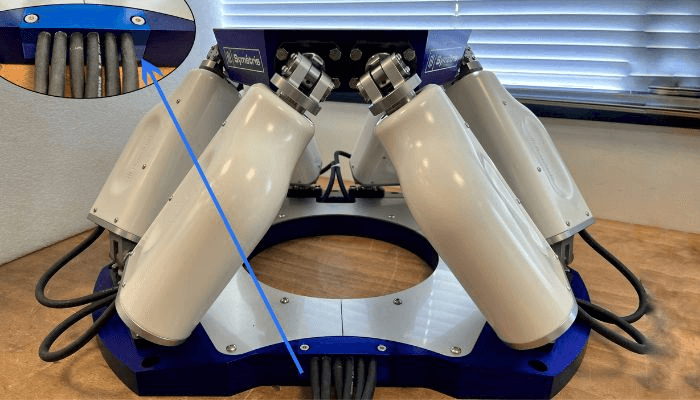

You may not have heard of hexapods before. According to Symetrie these are parallel kinematic mechanical systems with, as the name suggests, six legs. They are used to position or move an object in six degrees of freedom space with high accuracy, resolution and rigidity. The company itself has become one of the world's leading providers of hexapods solutions (for both positioning and motion applications) since its inception in 2001.

As mentioned, there are two different types of hexapods, both produced by Symetrie. The first are precision positioning systems, often used for beam samples, satellite mirrors or even telescopes. Second, there are motion systems that simulate the motion of a boat, truck, tank, or airplane. They are most often used to test and qualify sensors, optical components, inertial measurement units or gravimeters.

In particular, Symetrie's solutions are used specifically to meet the specific needs of industrialists and research laboratories, especially when it comes to large-scale technological projects (Laser MegaJoule Space Telescopes, JWST and GAIA). And it has a number of different applications. To name a few, hexapods are used in astronomy, automotive, defense, energy, medicine, naval, space, optics and many others. But how exactly can 3D printing be used to help create these machines?

The benefits of using 3D printing for hexapods

The decision to adopt additive manufacturing for Symetrie began as a way to solve a problem the company was facing. Symetrie has always designed, assembled and qualified its hexapods in-house at its premises. In recent years, however, the number of machines sold has increased significantly. Adding to this, supplier delays also increased as many saw especially during the COVID-19 pandemic which subsequently forced the company to sometimes delay its own deliveries to customers, obviously a situation that was not ideal.

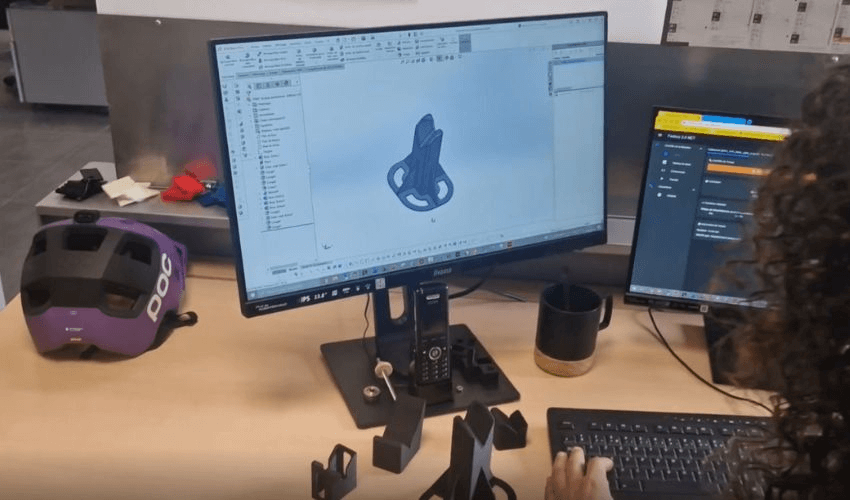

This led the company in 2022 to invest in a printer, specifically an industrial solution from OMNI3D – the Factory 2.0 NET 3D printer. And the choice was useful. This not only helped to compensate for the increasingly frequent delays on the part of the suppliers, thus allowing them to avoid delaying deliveries to customers , but they also reduced production costs , by producing more parts in-house.

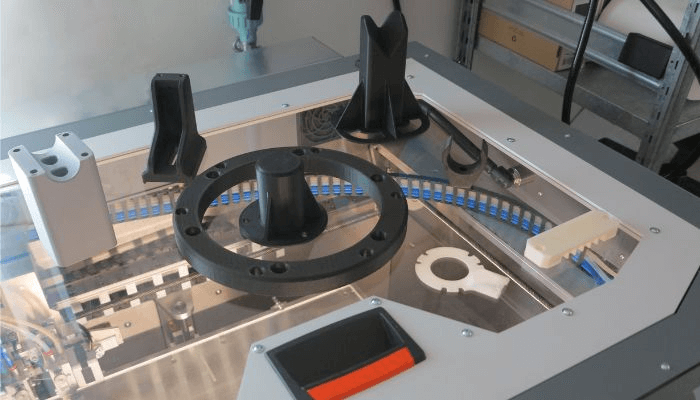

3D printing already plays an important role in various services in the company. For example, to create manufacturing tools to tune micromechanical systems, or printed blocks to place actuators in a precise and repeatable way during machine assembly. These parts were prototyped in PLA as thin as possible to validate the design, before final versions to be printed in just two hours using CF-PA12 to reduce the risk of breakage.

Irvin Stil, Production Manager of Symetrie notes: “ The OMNI3D printer enables responsiveness to unexpected production needs and the ability to produce parts that are impossible to machine.”

The 3D printer has been used to produce finished product parts such as cable trays for hexapods, spacers in the fixed platform, or PCB covers in less than 3 to 4 hours. This speed was particularly useful when the company was asked to produce a part in a hurry for a customer who needed an interface between Symetrie's HEGOA hexagon and an optocoupler system. They were able to print the part in CFPA-12 in six hours as opposed to several days or even weeks that would have been required if done by more traditional means.

Factory 2.0 NET from OMNI3D was also not chosen by chance. The printer has several features that were particularly appealing to Symetrie. For example, the large size allows simultaneous printing of a large number of small parts . But they also state the amount of material available for printing, a heating chamber, dual extrusion and the soluble media option (ODS20). All critical in industrial applications such as hexapods. You can learn more about OMNI3D by watching the video below:

0 Comments