You have a clogged nozzle and when the hot pull fails… you want to learn the method of cold drawing (cold pull ) for the 3D printer? Learn how to do it with PLA and other threads.

Repairing clogged nozzles can seem tedious, but before disassembling the hot end head, try the cold drawing method. This method uses thread and strategic temperature changes to unclog or clean the nozzle without dismantling the whole thing.

Also called "atomic pull" by Ultimaker, this procedure involves using a thread with a molten tip to pick up debris, as well as other small debris that clogs the nozzle and then pulling the thread to entice taking the blockage and debris with you. .

Repeating this cold pull several times can solve many nozzle problems without having to remove the nozzle and risk injury or improper reassembly. So this is usually the first thing you should try when facing a clogged nozzle. In this article we will show you how to perform a cold download as a first line of defense.

What you will need

Generally speaking, the best thread for cold drawing is nylon. It is usually recommended because it is naturally slippery and thus less likely to snap when removed from the nozzle. However, if you do not have nylon, choose your next most slippery and least fragile material.

In addition to the threads, you will need a cutter to cut a piece of thread to use and hold pliers on hand to use, while removing the thread slowly and steadily. And that's it!

Steps

Here's how to perform a cold download:

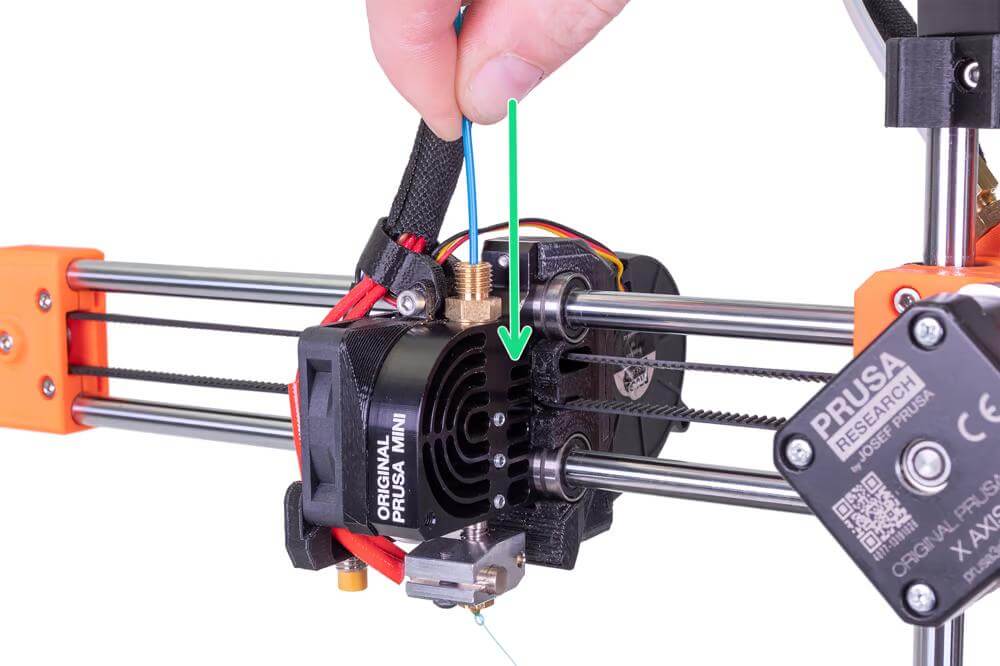

- If so, start by removing your Bowden tube from the extruder head.

- Heat the hot end to the printing temperature of your selected cold draw thread while removing the old thread.

- Pass the cold thread through the nozzle until it starts to flow a little.

- Cool the hot end by applying constant pressure to the thread. This ensures that the tip of the thread will take the shape of the inside of the nozzle during cooling.

- When the hot end is around 60 ° C, you can release the pressure. At this time, clogging or dirt is assumed to have stuck to the cold pull thread.

- Heat the nozzle again to the printing temperature of your thread and start pulling it out. Take this step more carefully if you are using PLA, as there is a high risk of breaking it instead of pulling it into a whole piece.

Advices

If you have performed these steps correctly, then you have already made a negative nozzle mold. Repeat this process until the nozzle is completely free of old thread or other contaminants.

If you do this with a thread the same color as the one that is stuck, then it can be very difficult to see your progress. It is always best to use a different color, with lighter colors being the best to show the removal of dirt, and nylon threads being the absolute best option.

If the cold drawing process does not resolve your clogged nozzle, make sure everything is clean. If you still have problems, you can try using a cleaning thread. If that doesn't help, then try other nozzle cleaning methods.

You can get our professional advice and guidance to solve this annoying problem by contacting us at 0885636868 and / or 3mgbonev.com, and / or Massenger / Viber / WhatsApp… do not hesitate to contact us!

0 Comments