Looking for 3D printing stronger than metal - learn about PEEK polymer. Our guide covers everything you need to know to get started.

PEEK (polyetheretherketone) is one of the most popular thermoplastics in the industry and has a good reason. PEEK can produce parts that are stronger and lighter than stainless steel and aluminum with extremely high thermal, chemical and wear resistance. Parts made from this engineering material can be found in almost every industry.

PEEK is valuable for supplying medical implants and aerospace components better than metal due to its high strength-to-weight ratio. It is ideal for electrical parts due to its electrical insulating properties and is widely used in applications requiring long-term resistance to pressure and wear, such as in the oil and gas industry.

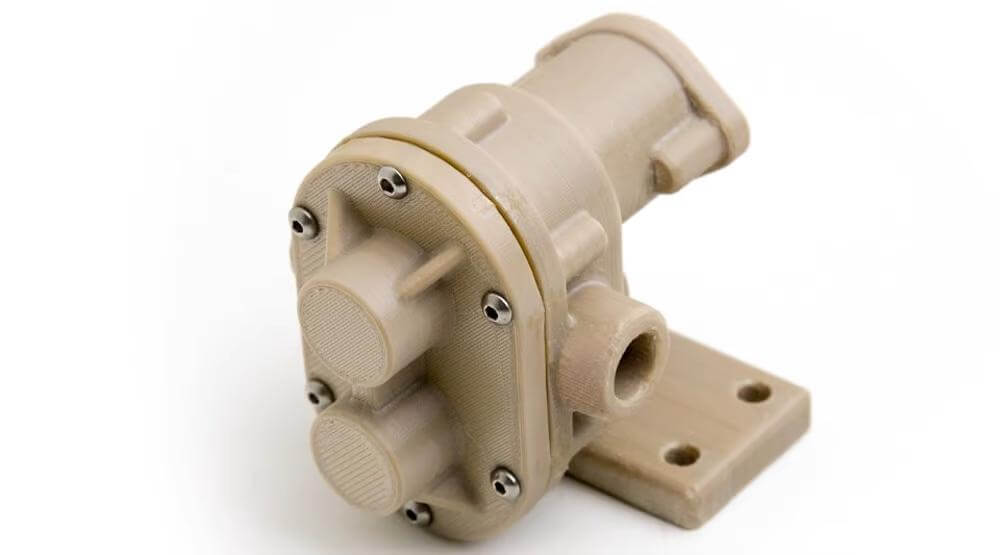

Combine the qualities of this plastic with the possibilities of 3D printing and you have the opportunity to make almost any custom shape and complexity of a part, from a material that can withstand even the harshest conditions. No wonder we see more use of 3D printed PEEK parts that replace metal in spacecraft, orthopedic implants and even engine parts in high-performance car racing.

At the same time, the demand for 3D printers that can work with this material is growing, which has led manufacturers to produce more affordable, larger and easier to use PEEK printers for companies that want to import production and prototypes in own company.

Although PEEK is still one of the most expensive polymers for additive production (still cheaper than most metals) and not the easiest to work with, today it is much more affordable than ever. Also, if you are new to PEEK (and other polymers in the PEAK family), read this article to learn more about this sought-after and functional material.

What is PEEK?

The UK-based company Imperial Chemical Industries (now known as Victrex) introduced polyetheretherketone (PEEK) in the 1980s. In its basic form, this material is a semi-crystalline polymer of high purity, comprising repeating monomers of two ether groups and a ketone group.

PEEK belongs to the family of polymers polyetherketoneket (PAEK), which also includes PEKK (Polyetherketoneketone), but overshadows the others because it can operate at higher temperatures and retain its excellent mechanical properties at continuous temperatures up to 240 ° C (464 ° F)), which allows it to replace metal in heavy environments for end use.

PEEK is one of the few plastics compatible with ultra-high vacuum applications, making it suitable for the aerospace, automotive and chemical industries.

Not all commercial PEEK products provide the same level of performance. You will find PEEK filament and powder from a wide range of manufacturers, but be sure to check the technical specifications and datasheets to make sure you get all the necessary PEEK qualities.

Special polymer manufacturers, such as Solvay and Evonik, make PEEK special for additive production and can advise you on the best ways to print their specific materials.

Do you need PEEK?

PEEK has many fascinating features, especially when it comes to producing functional prototypes and parts for regulated industries, but it is expensive and difficult to work with, so you have to ask yourself: Do I really have to print with PEEK?

Let's look at the pros and cons:

PROFESSIONALS

- Highly resistant to extreme temperatures up to 260 ° C (480 ° F), as well as corrosive liquids, gases and high pressure

- Insoluble in ordinary solvents, preventing its hydrolysis and allowing it to be used without any decomposition by water or steam under high pressure

- Remedy: PEEK has an inherently low specific gravity of 1.3 g / cm 3 , less than half that of aluminum and one-sixth that of steel

- High self-lubricating ability and low friction

- Exceptional resistance to resistance

- Very little wear

- Good dimensional stability

- Low flammability and low smoke on combustion

- Exceptional insulating properties

- Excellent resistance to sterilization at high temperatures

- Completely biocompatible

- Safe for food and resistant to oils and animal fats

AGAINST

- It must be processed at very high and constant temperatures

- More expensive than most other threads

- Low resistance to chlorine / bromide, concentrated sulfur and nitric acids, as well as to ketones and nitrobenzene. PEEK is also attacked by halogen and sodium, which limits its use in certain areas of industry

- Low resistance to UV light

- PEEK filament is highly hygroscopic and should be stored carefully and dried before use

- PEEK tends to distort and shift dimensions during printing if heat is not precisely controlled

Some of the distortion, shrinkage, and difficulty of printing with PEEK can be alleviated by combining PEEK with composite materials, such as glass fiber, graphite, or carbon fiber reinforcements. Annealing after printing can also enhance the quality of your details. The low UV resistance of PEEK can be circumvented by adding a layer of pigment, which consists of special soot particles. Carbon-filled grades provide improved UV stability and can be used in certain applications that require greater UV resistance.

Alternatives

If your part does not require all the qualities of PEEK, consider those alternatives that are easier to print and at a lower cost.

PEKK It is also part of the same family of polyaryl ether ketone semi-crystalline polymers as PEEK, but requires a lower processing temperature and has a wider processing window, which facilitates printing. PEKK is slightly more elastic than PEEK with good cushioning.

Last offers similar properties to PEEK, but at a much lower cost and is also easier to process at lower temperatures. Ultem has weaker friction and wear properties than PEEK. Ultem is the trade name for polyetherimide (PEI).

Carbon fiber reinforced nylon does not offer close to the strength or chemical resistance of PEEK, but is still an extremely strong material that is commonly used for fixtures, tools and many other industrial applications.

What is PEEK annealing and why do you need it

Annealing is a heat treatment and a general method of after-treatment of PEEK that can improve its mechanical properties. However, material scientists disagree on whether this is essential for each part. This is not a process unique to additive manufacturing, as it is also used in injection molded PEEK.

PEEK, as mentioned, needs high heat to process, but it also needs heat to change its mechanical nature. How much heat and for how long your particular part needs is also not easy to calculate. Contact your printer manufacturer for print profiles and guidelines, but you're definitely looking for some experimentation anyway.

A true understanding of PEEK requires knowledge of the materials science concepts of crystallinity and folded polymer chains and more nuances that we will not dive into here. Just be aware that your printer may include a warm-up setting or a list of warm-up options that you can follow, such as letting the component cool at exactly 10 ° C per hour to 140 ° C or leaving the component at 200 ° C for 1 hour for every millimeter of wall thickness.

3D printing tips for PEEK

Now that you have an in-depth review of PEEK, you may want to start printing with it yourself. Here are some basic tips and tricks to keep in mind when printing with PEEK:

CONSTANT TEMPERATURE

PEEK does not respond well to fluctuating or unstable temperatures. Therefore, a printer with a heated camera is highly recommended, if not mandatory. For best results while 3D printing PEEK, keep the 3D printer in an environment that undergoes minimal temperature changes, as well as away from solar radiation and high-traffic areas.

BE CAREFUL OF THE SPOTS

Occasionally you may notice black spots when printing with PEEK. Although there may be a number of reasons, the most common explanation is contamination of the printed material used or that the 3D printer has problems processing the required temperatures.

KEEP THE NOZZLE CLEAN

You should always clean the nozzle after the printing process is complete. All other materials must be removed from the nozzle, otherwise it may become clogged and possibly lead to stains (mentioned above).

BEWARE OF FAILED CRYSTALLIZATION

Occasionally, incorrect crystallization may occur when printing with PEEK materials. If parts of the print differ in color, such as brownish discoloration, as opposed to the standard beige color, this may indicate incorrect crystallization. This can be caused by temperature fluctuations during the printing process.

STORE FILAMENT IN A DRY PLACE

When not printing 3D with PEEK, you should store the material in a cool, dry, dark place until you use it again. In this way you will preserve the quality of the material and will ensure that you will achieve optimal results.

Not all printers can print PEEK

The PEEK thread reel may look like any other 3D printing plastic, but put it in a consumer machine and you will quickly realize that this material needs something more; in particular - more heat.

Not only do you need to extrude PEEK with a superheated nozzle (300+ ºC), but you also need to keep it hot with a heated bed and a heated chamber. The heat must be consistent and controlled, as how quickly you let the end cool down also matters. In addition, print speed and layer height are important factors for successful PEEK printing. Fortunately, better PEEK printers will automate many of these settings for a more worry-free experience.

Although most PEEKs are 3D printed using FDM filament printing, PEEK has recently progressed to powder form for selective laser sintering (SLS).

PEEK printers can print more than PEEK

If a 3D printer can print PEEK, then it has the ability to handle other high-performance polymers that have similar printing parameters and need high heat, such as PEAK, PEKK, PEI / Ultem, PPSU and others. Of course, they can handle plain ABS and even PLA if you can reduce the heat low enough.

What to look for in PEEK printers

Not all PEEK printers are the same, of course, and you'll need to balance your budget with the features you need in the printer and the ones you can live without. If you need PEEK from time to time or you are not sure if you need PEEK at all, try ordering your PEEK parts from a 3D printing service desk on request, such as 3MG Bonev Ltd.

Below are some of the best features of PEEK printers.

- HEPA filter to capture harmful fumes and particles

- Insulated chamber so that the heat does not heat your workshop or emit heat from your machine

- Fast heating chamber so you don't have to wait an hour or more before you start printing

- Double extruders so you can print support material in something other than PEEK, such as soluble material, to save costs and make removal easier

- Integrated thread dryer so your PEEK material is always ready to go

- Controlled cooling to prevent distortion

- Fast print speed

- Built-in camera for continuous print monitoring

- Power outage protection that resumes printing from where you left off

- Sensors to determine if you have enough thread to complete the job

- Thread jamming sensors

One of the best 3D printers with PEEK is MiniFactory Ultra.

Here is a brief introduction.

- technology - FDM (double extruders)

- Price: send an inquiry to us and we will send you an up-to-date offer - https://shop.3mgbonev.com/category/3d-printeri-minifactory-ultra

- Max. Extruder temperature. - 480 ° C

- Max. Temp. - 250 ºC

- Min. Resolution10 microns

MiniFactory (not to be confused with the 3D modeling platform MyMiniFactory) - is a Finnish manufacturer of 3D printers with a focus on industrial high temperature 3D printers. Its Ultra printer has an open system of materials that can work with a number of thermoplastics and includes automatic calibration, automatic and integrated post-processing, plus a replaceable carbon filter.

The machine also has servo motors, ball screws and linear guides to provide large, accurate and reproducible prints. On Ultra it takes less than 30 minutes to warm up and stabilize the printing chamber at 220 ° C. The heated filament chamber of the machine also monitors moisture and, if necessary, plugs into the heated dryer.

To make the printing process as simple as possible, data transfer works via USB in the miniFactory Ultra Basic. Alternatively, you can choose a security model, in which case the data transfer is done via WIFI or LAN connection of your choice. MiniFactory says their technology is designed for everyday industrial use and offers a warranty of up to five years.

PEEK parts on request

Not ready to dive into buying your own 3D printer for PEEK parts? Additive on-demand production is available for your PEEK and PEKK needs. If you are new to this subject or to additive manufacturing, experimenting with a few parts printed with a contract manufacturer may be the best way to prove your concept.

Many of the larger on-demand printing services offer PEEK printing and can be found as an option along with injection molding from manufacturers who specialize in high temperature polymers.

We from 3MGBonev Ltd. we can offer you 3D printing for your PEEK part with MiniFactory Ultra. Just contact us to order.

0 Comments