According to a joint report by WHO and UNICEF, 2.5 billion people need assistive devices such as wheelchairs, hearing aids or cognitive and communication support applications. However, nearly a billion of them do not have access to these vital aids. In addition, discomfort and pain are common problems with conventional wheelchairs. Addressing this challenge, LCS, a company specializing in wheelchair seating solutions, has announced its partnership with Create it REAL, a leading provider of 3D printing technology. Together they aim to introduce 3D printed wheelchair seats to Ireland and the UK, improving comfort and accessibility for users.

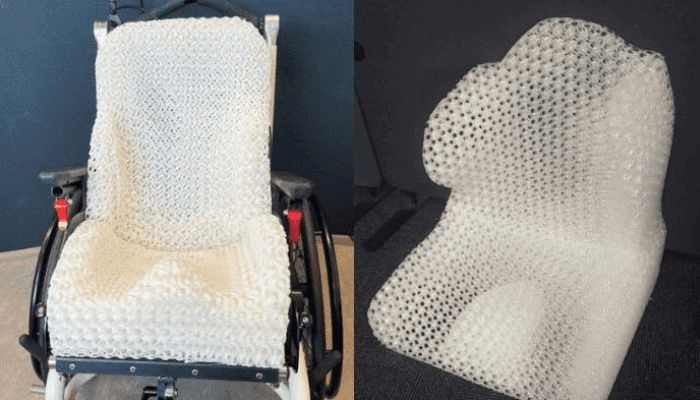

The presented product is a custom-made chair with the option of incorporating the WheelAir ventilation system. By integrating this system into the chairs, users can effectively regulate body temperature and maintain a comfortable skin microclimate, mainly through heat evaporation. This feature helps prevent excessive heat and humidity from building up. Currently, these 3D printed seats are recognized as premium offerings suitable for warmer climates.

Photo: Create it REAL

The comfort of 3D printed wheelchair seats

LCS currently manufactures custom seating solutions using the latest robotic milling technology. In this process, robots are programmed to cut and shape materials precisely. This method bonds foams of different densities, creating specific pressure zones that improve seating comfort.

Addressing the critical issue of seat comfort and health, the innovations behind 3D printed seats continue to revolutionize the industry. Speaking about the improved seat comfort, Luke Conway, founder of LCS, explained:

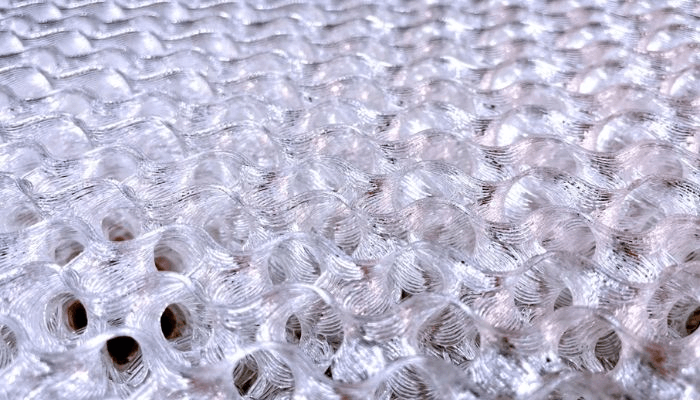

“ Heat and moisture are one of the contributing factors to pressure sores, 3D printed pillows allow heat and moisture to be easily drawn away from the skin. When we add WheelAir to the pillow, we create an active airflow through the pillow that provides a cooling effect for the pillow user. The 3D-printed gyroid structure is ideal for even distribution of air so that the temperature remains constant and the skin is not damp.”

Thanks to this partnership, LCS can now create fully 3D printed seats and incorporate pressure relief zones, which are also 3D printed, into sculpted foam systems. The main focus remains on user comfort. LCS claims their custom seats and cushions are of unmatched quality, featuring a well-ventilated internal structure that provides breathability. Additionally, their machine-washable design not only improves hygiene, but provides additional pressure relief that further increases comfort levels. Speaking about the seat foam, Jacob Nissen, CEO of Create it REAL, stated: “ Programmable Foam Ⓡ is not just an alternative to traditional foam, but represents a unique opportunity to produce seats with integrated softness and firmness zones to respond to user pressure and positional needs.”

Photo: Create it REAL

CS is currently setting up a local print center to meet the growing demand for 3D printed chairs in the UK and Ireland. Through an online portal, local retailers will be given access to upload custom designs derived from scans or choose from a range of pre-defined cushions. These pillows are customizable to accommodate each client's individual pressure and positioning needs.

0 Comments