When it comes to the Bambu Lab X1 Carbon, speed is one of its best features. But how fast is fast? Read on to find out!

X1 Carbon is Bambu Lab's flagship printer. We're talking about a high-performance 3D printer that came out a year ago with tons of features unheard of in the consumer market. Bambu Lab also offers P1P and P1S as more budget options, but at the cost of some of the features they did X1 Carbon to stand out in the first place – for example, the innovative lidar sensor and the AI camera for detecting printing errors.

With a top speed of 500mm/s and an acceleration of 20,000mm/s², this printer stands out as one of the fastest on the market while delivering great quality prints. In this article, we'll look at the design decisions they make X1 Carbon so fast. We'll also take a close look at its speed stats, touch on material considerations and compare print times to competitors using none other than the dear old Benchy.

Design

X1 Carbon is a fully enclosed CoreXY printer with a build volume of 256 x 256 x 256 mm and a hot end that reaches up to 300 ºC, making the machine capable of printing all consumer materials and some engineering grade materials such as PC, PA, ASA, as well as materials , reinforced with carbon fibers.

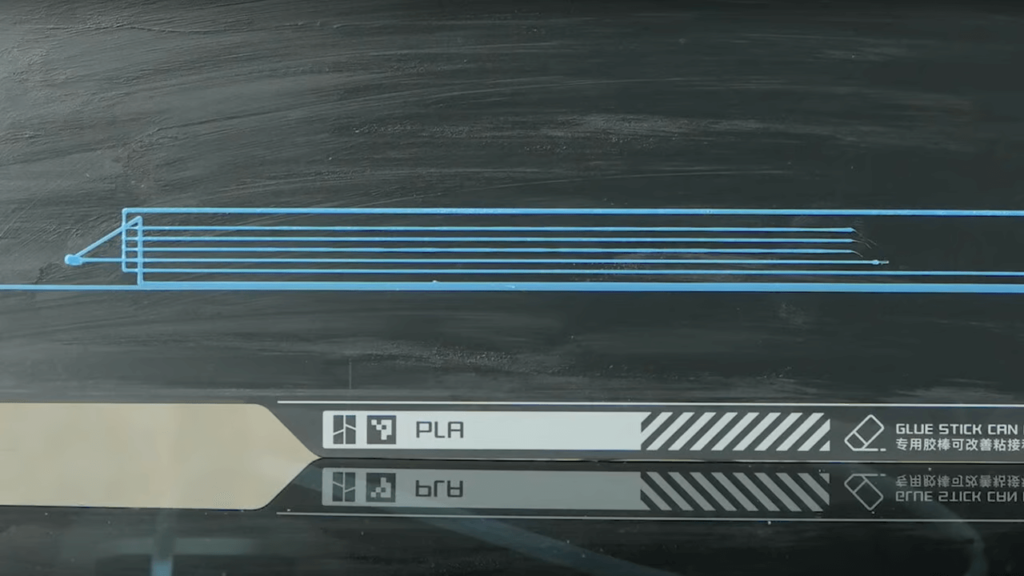

The CoreXY motion system can be found on most high-speed printers today and is characterized by the fact that the bed only moves vertically along the Z-axis, while the XY movements of the printhead are controlled by a pair of stepper motors. This allows for faster acceleration than the more common bed threshold design, where the entire bed and printed object moves along the Y axis.

The steel frame and aluminum housing add much-needed strength to combat any vibrations those fast movements can cause. The effects of these vibrations are further reduced by an active vibration compensation feature, which we will discuss more below.

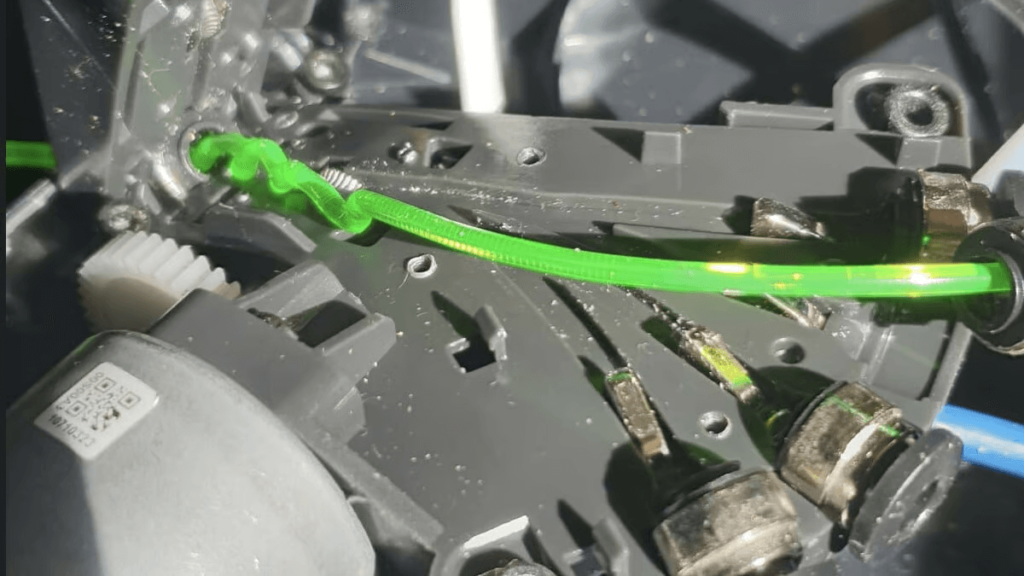

The print head is designed from scratch with a custom extruder, hot end, breakout board and leveling system. This means that you can't easily replace any of these parts with third-party equipment, but it also means that the whole kit is perfectly matched for maximum performance. It's a light and powerful setup that will 'push' through a lot of material, really fast.

Statistics

Excuse us for getting into technical details now, but there are some impressive stats that the speed fans among us will want to know:

- The tool head can move at 500 mm/s with a maximum acceleration of 20,000 mm/s 2 .

- The 40W ceramic heater allows the proprietary twin gear extruder to pump filament at 32mm³/s.

- The hot end reaches 200 ºC in 31 seconds and 300 ºC in 1 minute and 9 seconds.

- The build plate is heated to 60 ºC in 38 seconds and 120 ºC in 2 minutes and 15 seconds.

As the printer comes fully assembled, these are the numbers that are ready to go – no tinkering required.

In addition, after starting printing, four firmware speed modes can be activated on the printer screen. All they do is multiply the speed of the engines, but it's still nice to have them there. Firmware speed modes are Silent (50%), Normal (100%), Sport (124%) and Ludicrous (166%).

While it's common to upgrade parts from other printers for speed, the closed and proprietary nature of the X1 Carbon limits modification options. That being said, the folks at Bambu Lab have ensured that every component and design choice makes it powerful enough to reach the target speeds, resulting in a well-balanced printer with no apparent bottlenecks.

Quality

Moving fast is only half the battle. The other half, and definitely the hardest, is doing it while maintaining quality. This printer features a significant array of sensors and calibration tools that enable high speeds while maintaining print quality.

The automatic bed leveling setting is now standard in most printers, but the lidar sensor of the X1 Carbon kicks everything up a few notches. Not only does it map the entire print surface for perfect first layers, it also facilitates optimal extrusion. With the extrusion and flow test, several rows of filament are printed, then the lidar sensor measures them to determine the best pressure settings. At the speeds of X1 Carbon, calibration of each type of flow thread is mandatory and this feature automates the entire process.

There is also an active vibration compensation function that eliminates most of the "ringing" and "banding" problems that occur with increasing speed. This is an algorithmic solution similar to input shaping found in the Klipper firmware.

Material considerations

The closed chamber and high temperatures allow for a wide range of materials and with them many settings. Fortunately, there is such a thing as presets. After a year of updates, Bambu Lab has dialed almost all of them to perfection on their own slicer Bamboo Studio . For example, the built-in presets will make printing with PETG slower than with PLA or ABS, and that's on purpose because that's just how PETG prints.

When we change thread profiles in the slicer, the speed adjustments may not be obvious because profile settings like walls or fills show the same speeds. However, they will be adjusted by the thread preset and you can see the speed change in the slicer preview.

Then there's TPU. Speed and TPU just don't mix. It is a slow material that is roughly limited at a bulk velocity of 5 mm 3 /s. Fortunately, Bambu Lab recently released a TPU filament that is optimized for high-speed printing, so you're more likely to take advantage of the capacity of X1 Carbon for quick printing.

But if you're printing with a third-party TPU or plain old Bambu Lab, it's not a good idea to change the firmware's speed modes to 'Sport' or 'Ludicrous'. And according to the official instructions, the TPU should not be charged via the optional AMS!

How fast is fast?

Print speed is an objective measure. Speedboat is great and has rankings for specific models. However, for this article we are only considering quality print jobs. So you can expect the numbers presented here to be realistic expectations of what a normal print job would be.

X1 Carbon there is strong competition. The Prusa MK4, AnkerMake M5, and Creality K1 all come at lower price points, albeit with fewer quality features. These are all fast hobby printers capable of printing acceptably Benchy in less than 20 minutes where most printers usually take about an hour:

- Prusa MK4: 12 minutes and 30 seconds

- Bambu Lab X1 Carbon: 12 minutes and 38 seconds

- Creality K1: 17 minutes and 22 seconds

- AnkerMake M5: 17 minutes and 41 seconds

The Prusa MK4 does have a slight advantage when printing small models due to the calibration that X1 Carbon does at the beginning of each print (this can be turned off, by the way). However, being bed-friendly, the MK4 can't handle it if the model is tall, as Y-axis movement causes the entire print to shake. So, as the complexity and size of models grow, X1 Carbon actually begins to gain a greater advantage. However, in some cases, the difference is not so great if you judge it only by the speed.

This amazing printer Bambu Lab X1 Carbon, you can find with us 3MG Bonev Ltd. at the link below:

https://shop.3mgbonev.com/product/3d-printer-bambu-lab-x1-carbon

https://shop.3mgbonev.com/product/3d-printer-bambu-lab-x1-carbon-combo

0 Comments