3D bioprinted skin, which is as close as possible to the real one - is not science fiction, but a completely real breakthrough of scientists from the Wake Forest Institute of Regenerative Medicine in the USA. This should come as no surprise – 3D printing has long altered classic manufacturing models in many industries, including aviation and aerospace.

No one doubts that at the current furious pace, it was only a matter of time before technology entered health care and medicine in a particularly dynamic way and became a part of us. Quite literally, as the skin example shows.

In experiments with mice and pigs, the Wake Forest researchers found that the tissue they created could seamlessly integrate with real tissue and thus speed up wound healing.

The discovery is important because it could provide new technologies for treating severe burns.

„Comprehensive skin healing is a significant clinical challenge affecting millions of underprivileged people worldwide", wrote the study's lead author, Dr. Anthony Atala.

„Our results show that creating bioengineered human skin with sufficient density is possible", he adds.

Bioprinting has been developing for over a decade now as a technology for replicating objects that mimic natural tissues, bones and blood vessels in the body. It is mostly associated with drug research and provides an alternative to the animal models used in preclinical research.

Recently, more and more bioprinted products also act as cellular scaffolds to help repair damaged ligaments, joints and cartilage.

In the case of Dr. Atala's team, they have succeeded in artificially creating fully functional three-layer skin using all six major skin cell types, along with specialized hydrogels that act as a bioglue.

When transplanted onto mice wounds, the bioprinted tissue was able to form blood vessels and develop normally. The result is rapid wound closure, less skin shrinkage and more collagen production, resulting in less residual scarring.

The same results were obtained in pig wound experiments.

Lab-produced skin has long been a field of medical research, but now, for the first time, a product with similar complexity and density has emerged that achieves complete wound healing.

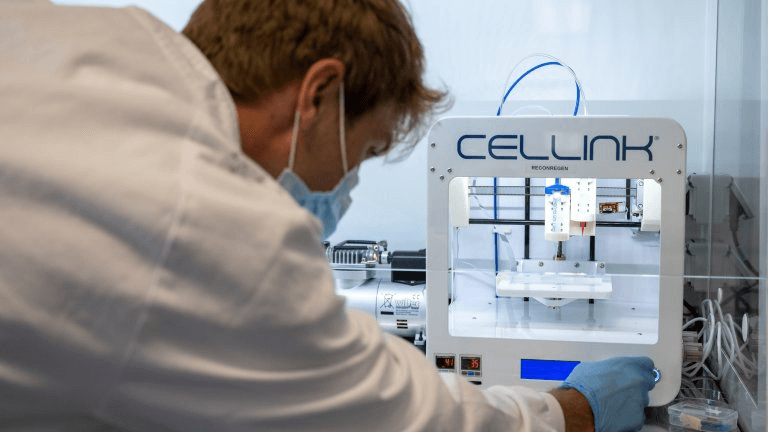

The Wake Forest Institute has already created a mobile 3D printer.

In the future, such a machine could be placed at the bedside of a severely burned victim and regenerate his skin layer by layer on the spot.

„So far, we have been able to print flat structures like skin, tubular structures like blood vessels, and hollow ones like bladders. With larger organs, it becomes complicated because of the sheer number of cells per square centimeterAtala says.

The hope is that in the near future it will become possible to print functioning human organs.

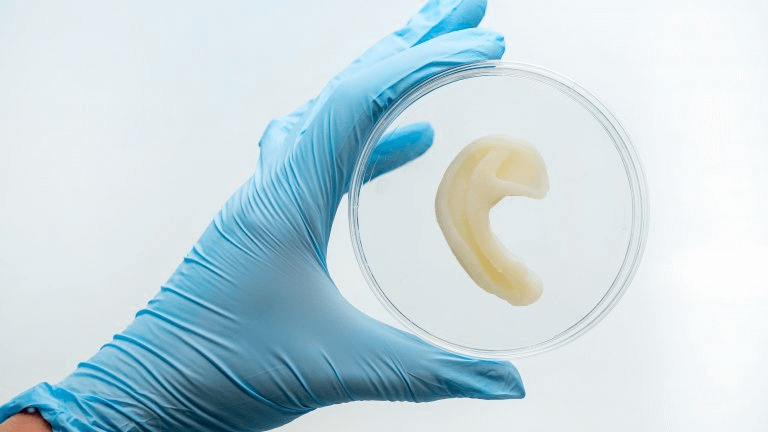

For example, last year in the USA a successful external ear transplant was performed on a girl born with a malformation.

„I think in less than 20 years we will be creating organs for transplantationProfessor Tal Dvir, an expert in tissue engineering and regenerative medicine at Tel Aviv University, told Fortune. "We'll start with simple structures like skin and cartilage, but then move on to more complex tissues and get to the heart, liver, and kidney.„

A rabbit-sized 3D-printed heart has already been created in Dvir's lab. It has working cells, chambers, major blood vessels and even a heartbeat.

The professor notes that a human heart would use similar technology, but with a much more complex scaling process.

The method aims, in the long term, to offer a solution to the obstacles faced by a number of patients in need of an urgent transplant. There is a significantly lower chance of rejection if the organ is made from the recipient's own cells.

„I think that in the future we will not need donor hearts and lungsTal Dvir thinks. "I am optimistic that within 20 years we will be implanting working bioprinted organs into people.“

0 Comments