With 1 million parts, Merit3D delivers the largest order ever for 3D printing

3D printing may not yet be cheaper than injection molding for mass production, but the savings come from value-added innovation.

Utah-based 3D printing service Merit3D is halfway through an order for 1 million parts from Adhesives Technology, a Florida-based manufacturer of construction and industrial adhesive products. How did they get the largest 3D printing order and why was 3D printing the better choice over injection molding? We'll bring you a conversation with Merit3D CEO Spencer Loveless to find out.

It all started with a supply chain disruption.

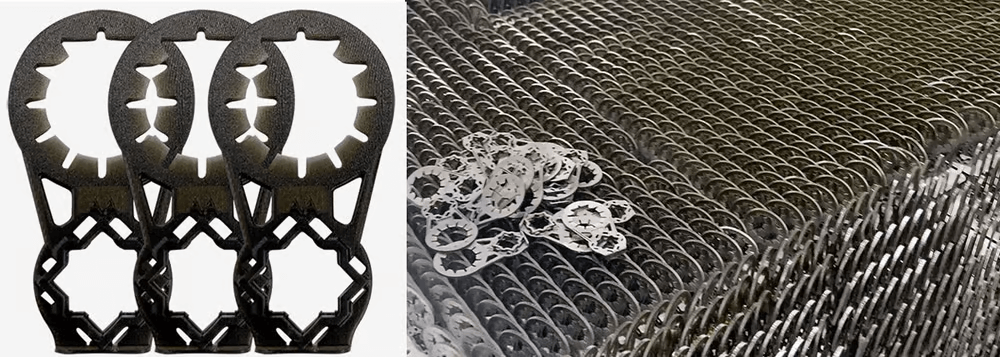

Adhesives Technology uses specially designed, injection molded plastic components to bond two of its related products together. These little hangers, in several different designs, ensure that the mixing nozzles stay with their respective epoxy cartridges and do not separate in transit or on the retail shelf. Out of this part and ... thousands of orders are at a standstill.

This is exactly what is happening with Adhesives Technology. The company makes dozens of industrial adhesives shipped across America, but without this simple plastic part, operations nearly ground to a halt.

Injection is done all over the world, and the most economical suppliers are often in places where sudden instability can occur - earthquakes, virus outbreaks, embargoes and sanctions. However, transferring injection molding to the US is time-consuming and expensive. The molding tool used to make just one version of the Adhesives hanger was a multi-cavity mold potentially costing hundreds of thousands of dollars to recreate. The more complex the mold, the higher the cost of the molding tool.

“A contact at Adhesives Technology's Utah office saw one of our social media posts and reached out to see if we could help,” says Loveless.

Initially, the idea was to turn to 3D printing as a stopgap or potential bridge until new injection molding tools could be created.

Redesign the part for 3D printing

Of course nozzle hangers can be 3D printed. Merit can scan the 3D hanger, create a digital file and start production. But in its current design, the coat hanger would have been too expensive to 3D print because one part of them couldn't fit in one run of the 3D printer. The project will require more printers and therefore more material and more time.

"There's a perception that if you have a digital design of a part, you can just go from injection molding to 3D printing," says Loveless. But that usually doesn't make economic sense. Just as this original part was designed to be injection molded, redesigning it for 3D printing was the only way forward.

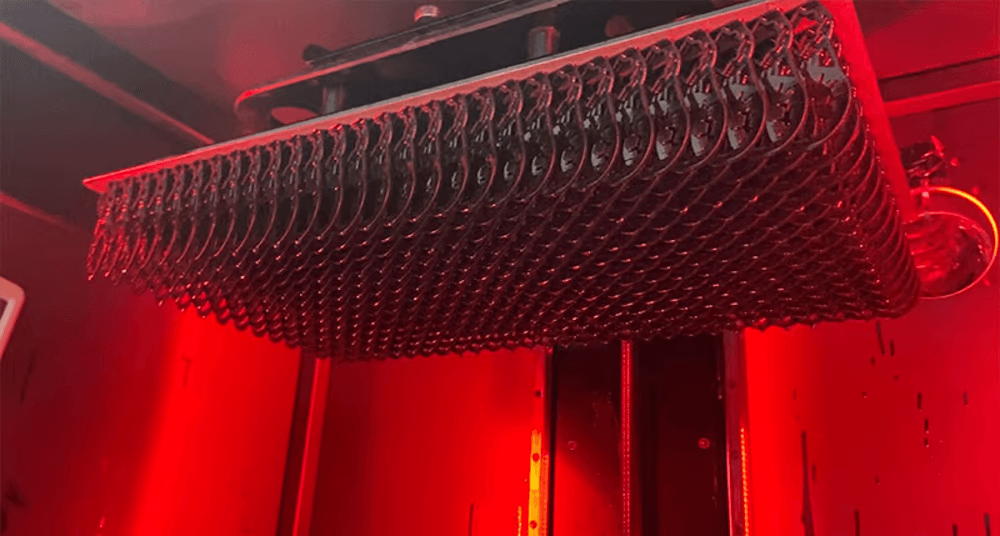

It took Loveless and his Merit3D engineers two weeks to evaluate the hanger's purpose and properties and redesign it. Through several iterations, they developed a part that was smaller, lighter, aesthetically pleasing, and used less material to make. It is more critical that 400 pcs. can fit into one print on their 3D resin printers, of which they own 24. Each print takes just under 4 hours. The price dropped dramatically and Adhesives Technology found its temporary solution.

After receiving an order that would lead to Adhesives Technology in several months, Merit3D presented them with another iteration of the design. They called this a universal hanger because it will work on two products that previously had different hangers. This would eliminate another hanger that Adhesive Technology had to inject, transport, store and apply, plus another injection mold tool that had to be recreated.

"After we came out with the universal hanger, all of a sudden their quantity went from x to y because we just eliminated another SKU they had to carry," says Loveless. Adhesive Technology then expanded their order with Merit3D.

Although the 3D printed hangers were more expensive than the injection molded versions, Adhesives Technology sold on the added value of continuous innovation and improvement.

"With 500,000 units, we plan to make it better again," Loveless says. This time, Merit3D plans to take advantage of another attribute of 3D printing; ability to consolidate parts into one 3D printed part. "Right now they have the mixing nozzle, hanger and cap as three separate injection molded parts, but our game plan is to see if we can combine all of those into one piece."

This innovation will save Adhesives Technology even more SKUs.

Is 1 million just the beginning?

Today, Merit3D supplies 40,000 parts per week to Adhesives Technology, produced on 10 of their Photocentric printers. Even now, Merit3D is working with Photocentric and its raw material suppliers to find the optimal combination of properties and price for a new 3D printing resin that will allow them to make more innovations and even thinner hangers that have equal or better mechanical properties than the current one.

Although 3D printing has revolutionized the prototyping space, to compete with injection molding for mass production, it is a battle of the materials. "We compete with traditional plastics like ABS, polypropylene, nylon and polycarbonate," says Loveless. "It's a cheap material and we're losing a lot of business because the cost of 3D printing material is still too high."

The photosensitive resins used in the scope of 3D printing called "bath polymerization" are often patented. New engineering-grade 3D printing resins are coming to market regularly, but there isn't an abundance of options right now.

"Our goal at Photocentric is to facilitate additive manufacturing solutions that are industrial, scalable and affordable," says Sally Tipping, the company's commercial director. “There's still that price difference between additive manufacturing and injection molding, but largely our goal is to lower the cost of materials.” Photocentric is an open materials platform, meaning users can work with materials manufacturers to develop custom resins.

Back wave to additive manufacturing

Can adhesives technology take these innovations for Merit3D parts and return to injection molding in the long run? Possibly. But there are forces, both economic and legislative, that are actively encouraging US companies to invest in new technologies to shift manufacturing and return to "Made in America."

Merit3D benefited from state-level grants to purchase equipment and robots that reduced the cost of the adhesive technology project.

"We are very active on the front lines with the USA and the state of Utah to find new ways to redirect production," Loveless says. "This is a great example. This is probably the largest private order in the history of 3D printing.”

There is no doubt that Adhesives Technology's project with Merit3D is a huge step in the development of additive manufacturing to compete with injection molding.

"The future is untold," notes Loveless. "Depending on what happens with their mold and everything else, our goal is to add enough value to the product that they can say, OK, we're not going back to our injection mold."

0 Comments