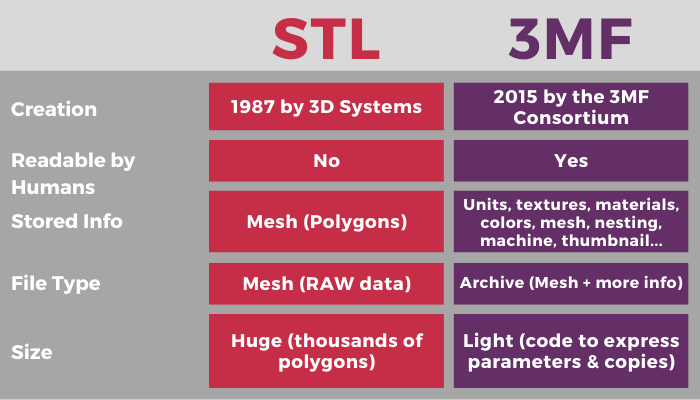

Created in 1987 by 3D Systems, the first company specializing in 3D printing, the STL format is now the most common on the market. This stands for Stereolithography (or Standard Triangle Language) and is found on most platforms that offer 3D models, such as Thingiverse.

MyMiniFactory and Cults.

The 3MF format was developed by a consortium led by Microsoft. Released in 2015, the format is already attractive due to some of its unique properties. Also called 3D manufacturing format, 3MF models are designed to be understandable and limit errors during the printing process.

Characteristics of STL files

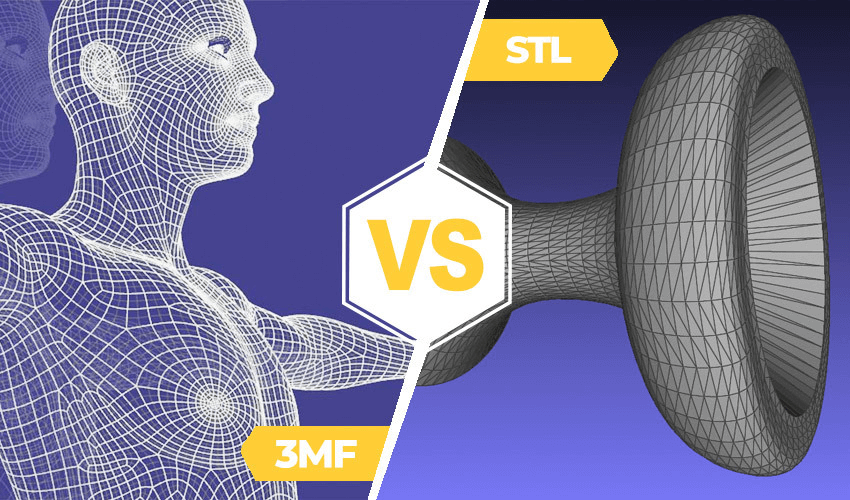

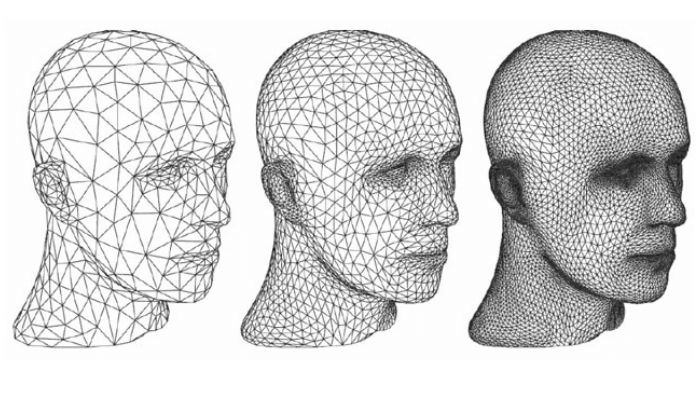

Since its inception in 1987, STL has been the most popular format for 3D printing users. Compatible with all slicers and CAD software, STL files are now mainly used in the rapid prototyping industry. As the abbreviation indicates Standard Triangle Language, the format "plays" each pattern using triangles. In other words, the STL format recreates a 3D model as close to its shape as possible using thousands of triangles. Specifically, a flat surface with 4 sides is necessarily divided into 2 triangles. Thus, if we take an example of a cube, it is divided into twelve triangles, given that it has 6 faces.

The accuracy of the print also depends on the number of triangles. Modeling a face, for example, requires a lot of triangles. All these triangles are intended to be as close as possible to the shape defined by the 3D model. However, they do not contain information about the manufacturing process, material, texture or color. And right here lies one of the main limitations of the STL format.

The more precise the STL format, the more triangles it contains

Despite their large size, STL files only contain information that allows the geometry of a part to be established. However, by using a slicer, the user can still add various printing (slicing) parameters to the model/STL file. These parameters can only be saved in 3MF format.

Another problem with STL is the frequency of corrupted files. When a file is defective, usually due to a problem during conversion, the user is forced to repair it. Therefore, following the example of Netfabb and Meshmixer, several repair programs exist. They allow to correct the defects of 3D files. But using such software adds an extra step to the printing process. Finally, the STL format is unreadable by humans, only compatible software can understand and therefore interpret it.

Characteristics of 3MF files

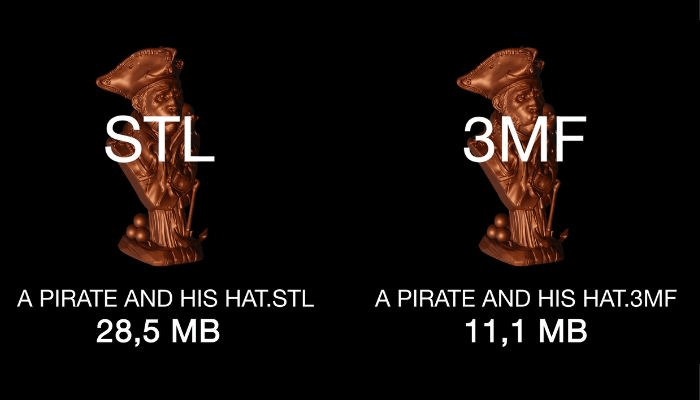

Much newer than the STL format, 3MF is the result of a consortium founded by Microsoft that includes Dassault, Autodesk, Stratasys, and UltiMaker. At its launch, Adrian Lannin, CEO of the 3MF Consortium, revealed the project's aims: "3MF empowers people, maximizes productivity and unlocks the full potential of 3D printing." Designed to provide professionals with a viable storage solution for 3D files, the 3MF format stands out for its "light weight" and the large amount of information a file contains.

3MF files, unlike STL, are not just a mesh. They are archive files (similar to .zip) containing both the 3D model (such as a mesh) and the information related to the production of the model, such as production methods, materials or assemblies. On this matter, Microsoft explains: “3MF is a file format specially adapted for 3D printing and Windows. 3MF includes colors, textures, scaling, containing recommended print options, and many other improvements.”In addition, a 3MF file is encoded in XML, making it human-readable, not just machine-readable. So if you replace the .3MF extension with a .ZIP extension, you can open any file in the archive to discover its characteristics. In addition to its openness (easy readability), it is also more intelligent as it offers a better understanding of network errors. Avoids problems related to geometric varieties (manifold), which prevents self-intersection, "non-manifold" patterns, and mesh holes.

Currently, the main limitation of the 3MF format lies not in its properties, but rather in its lack of popularity. Despite the various limitations associated with its features, today STL is much more democratized than 3MF. This phenomenon is particularly noticeable in the various sharing sites such as Thingiverse, Cults or Printables. And other shortcomings remain. For example, there is a lack of integration with certain slicers and CAD software that are currently incompatible with this format. Additionally, there is a lack of cross-compatibility between slicers, as some parameters configured in one slicer will not necessarily carry over to another slicer when opening the same project. However, we can hope that in the future, if 3MF gains popularity, efforts will be made to address these issues. Especially since it is an archive file with XML code and therefore can be improved. One can imagine cross-compatibility allowing easier sharing of files that can be correctly interpreted by different slicers.

The specific advantages of 3MF vs. STL

Imagine you have a 3D printer and want to print a complex model. If you need outside help, such as a printing service, they can configure the model in slicing software with all the relevant parameters and then export that configuration in 3MF format. In this way, you will find in one file your model, but also the print profiles, possible modifiers and other parameters. In the same case, using the STL format, the manufacturer would have to export the print profiles in addition to the network, but even when sharing these profiles, information such as modifiers would be missing.

Now imagine that you are a designer who wants to share your 3D models on the Internet, for example on Thingiverse, Printables or Cults. Using the 3MF format, you can embed material information or modifiers that simplify the 3D printing process. The 3MF format also allows you to define the license and associated copyrights. You can also add your name and description to the file. So, all of this information is stored in the file, not just on the download page of the site, if your model is shared outside of the site where you originally shared it, all of this information will be preserved.

Is 3MF the format of the future?

As you can see, 3MF will probably become the standard in the future. Seduced by its properties, several technology experts have already adopted it. Charly Le Roy, co-founder of Polyfab, a company that resells 3D solutions and provides training, explains the reasons for this choice: “The main difference, in my opinion, is the amount of information stored. STL only contains the 3D model, its counterpart 3MF contains the model, but also its orientation, its supports, its print parameters… So 3MF is much more practical for the needs of multiple iterations.” The opinion shared by Michael P. Bourque, Director of Digital Manufacturing at Boston Engineering,“I can't believe that STL is the most common format among 3D printing enthusiasts. STL is a terrible format for reproducing model geometry and is only used because the slicing step is fast. […] I prefer 3MF because it is self-contained and can contain additional data to reduce problems.”

Due to its ability to limit the risk of error and facilitate the sharing of models, the 3MF format seems much more suitable and can stand the test of time. One promising sign of this is the fact that the American giant 3D Systems, creator of STL in 1987, decided to join the 3MF consortium at its launch in 2015. Charly Le Roy concludes: "The format that will be used to share of projects for printing through libraries of ready-to-print models will definitely be the 3MF format. This naturally limits the risk of error and saves time when manufacturing parts.”

0 Comments