If you're thinking of buying a 3D printer for your small business, we've picked the best options that are easy to use but produce high-quality, reliable parts.

When buying your first 3D printer for your office, lab, studio or workshop, the first thing you should consider is ease of use and vendor support.

Your printer should contribute to your company's overall productivity and speed to market. It should save you money and effort. You can't afford to waste time with multiple manual controls that require the expertise of a veteran printouts that fail due to unreliable mechanics or no one to call for help.

We have selected some of the easiest to use and most reliable machines on the market that also have some of the best software and backup support. They have a complete ecosystem of hardware, software, materials and expertise to help you get the most out of your 3D printer purchase.

As the 3D printer market becomes more saturated with hobby machines of varying quality levels, mid-range machines are improving their technology and expanding their feature sets to appeal to business users. Manufacturers in the $3,000 to $ 20,000 range focus on appealing to a broad range of professional customers through enhanced ecosystems of interoperable software, hardware and materials, along with near-one-button printing capability.

Whether you're an architectural firm looking to print better and faster models or a metal parts manufacturer looking to print more innovative designs and save on raw materials, adding 3D printing to your workplace is a smart decision.

Now let's take a deeper look at our top picks for your company's first 3D printer.

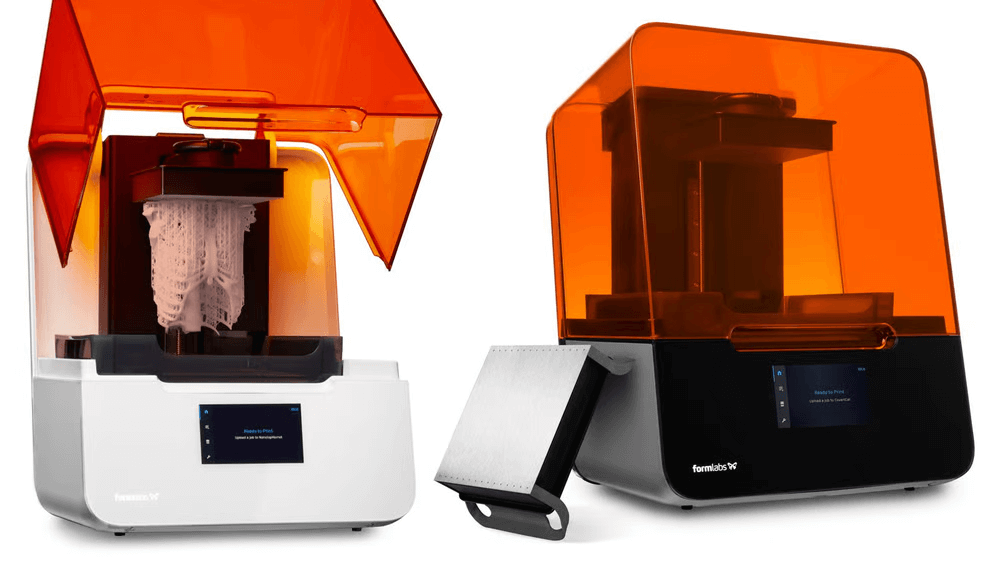

Formlabs Form 3+

Formlabs resin printers are as close to one-click printing as you can get in a desktop resin machine. Their ecosystem of business software, materials, printers, post-processing accessories and printing resources is a complete package that almost guarantees easy and flawless printing. If you're new to resin printing, you'll appreciate Formlabs' material cartridges, which make printing and cleanup easier than pouring resin from large bottles.

Form 3+ produces smooth surfaces that are particularly good for prototypes and proofs of concept, while the engineering-grade materials make it a workhorse for highly accurate, functional 3D prints that can replace finished parts and withstand the rigors of the 'factory floor.' These printers are also very popular with jewelers and artists for their fine detail.

Plus for businesses, Formlabs software offers a dashboard so employees can queue up print jobs and monitor printer activity from anywhere. Printers, whether you have two or 20, network together to easily scale print output. Support is another strength of Formlabs. On their website, you'll find a library of in-depth guides, step-by-step tutorials, and webinars. You can also upgrade the Basic Warranty to a Professional Service Plan or Enterprise Service Plan, which includes priority email support, expedited troubleshooting, live training sessions and remote printer health monitoring.

In 2023, Formlabs introduced a new hardware and software solution that allows your printers to print parts around the clock without your help. The new Formlabs Form Auto is a hardware extension for Form 3+ that automatically removes finished parts from the build platform and deposits them into a storage container ready for Form Wash, then starts the next print.

- Technology: resin (stereolithography, SLA)

- Price: estimated price -$4,200 ($9,999 with accessories and materials). For an offer, contact us at 3mgbonev@gmail.com or phone 0885636868;

- Ideal for: architects (models), jewelry designers (wax casts), product designers (detailed prototypes), dentists (dental models), manufacturing (cases, molds)

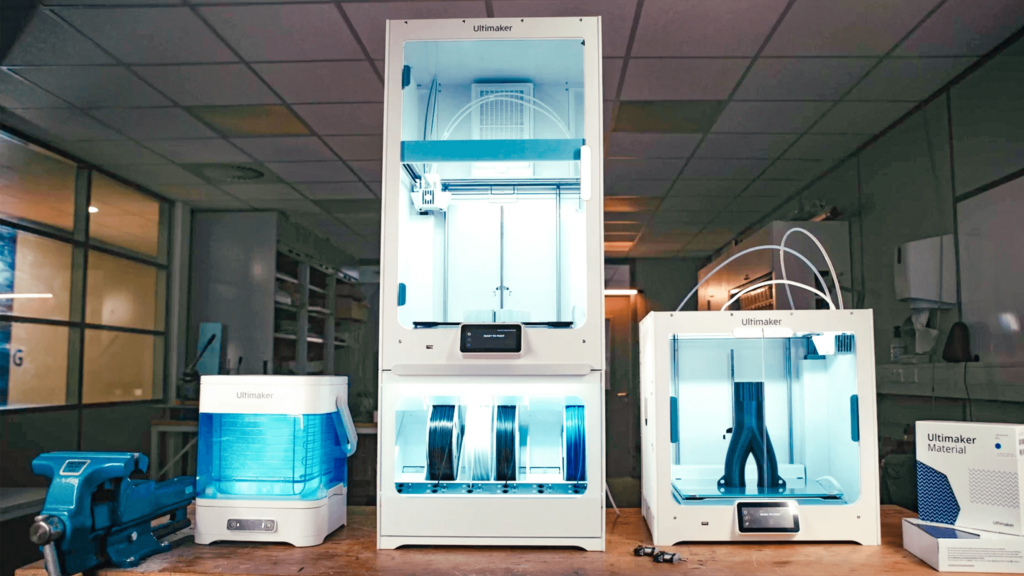

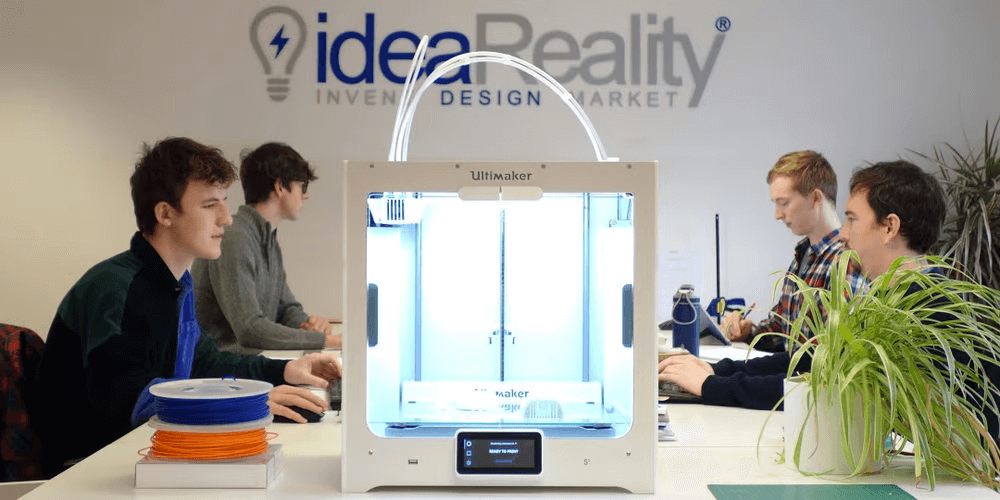

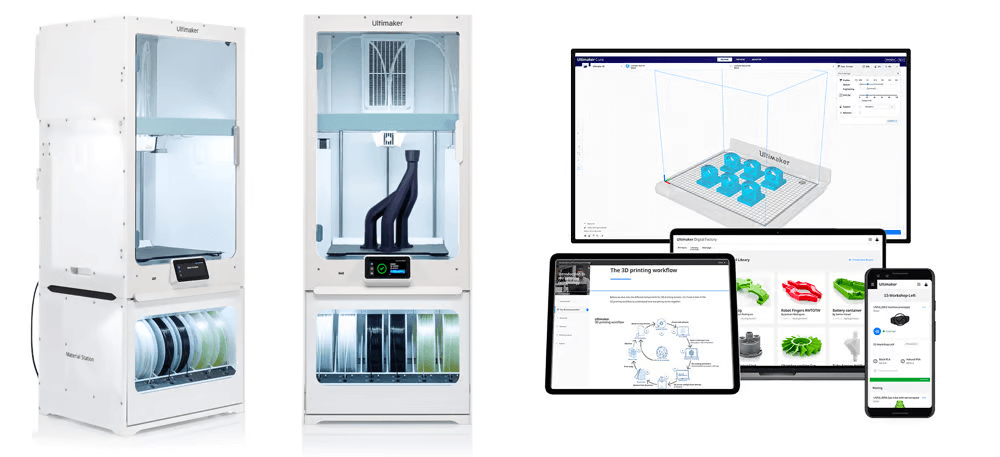

Ultimaker S7 Pro Bundle

UltiMaker offers a complete 3D printer solution, but not just a machine. The company has 3D printing packages that include hardware, software, materials, and access to the company's 3D Printing Academy, all at a convenient package price.

UltiMakers are really easy-to-use twin-extruder machines, perfect for prototyping, tooling and spare parts, with filament and 3rd parties that let you print with virtually any filament, plus a new metal filament for metal parts. The company's partnerships with material manufacturers ensure that UltiMakers are verified to provide optimal prints from a wide range of specialty filaments, including industrial-grade engineering plastics. The printers even recognize which media you have installed and automatically print with the appropriate settings.

UltiMaker has also taken the guesswork out of keeping your materials in optimal condition, as exposure to moisture, heat and cold can lead to failed prints. The S7 Pro includes filament humidity control and automatic material handling – if the filament runs out or you start a new print that needs a different material, the material station automatically switches to the next spool.

UlitMakers are easy to network and scale for printing farm production. The relatively new Ultimaker Essentials software-as-a-service allows companies to deploy 3D printing across the enterprise with a central hub, enhanced security and software updates every two years. Their eLearning platform includes question and topic oriented videos covering the basics to complex questions and even awards certificates of completion.

UltiMakers are ubiquitous in a number of industries, from automotive and art to healthcare and engineering, with good justification for purchasing.

- Technology: filament (fused deposition modeling, FDM)

- Price: Estimated $12,000 for the S7 Pro package plus materials For an offer, contact us at 3mgbonev@gmail.com or phone 0885636868;

- Ideal for: product designers (functional prototypes), manufacturing (gadgets, boxes, molds), teachers (models, prototypes), cars (prototypes)

Markforged Mark Two

The big appeal of the Markforged Mark Two printer is its ability to deliver strong metal parts without metal. Especially valued by automotive and mechanical design engineers, its carbon or Kevlar fiber prints can replace traditionally machined aluminum tools, fixtures and functional prototypes at a fraction of the cost and time. Mark Two is easy enough to use that businesses of all types can skip the machine shop and print from their desktop.

Like the others in this collection of ideal entry-level business printers, the Markforged backs solid technology with solid software. The cloud-based 3D printing software Eiger The company's solution includes a digital parts library, print preparation and remote management of the printer fleet in one platform. The software Blacksmith works to make your prints even better and more consistent by connecting your 3D printers with your inspection equipment to ensure that every part is produced according to design.

Providing better resolution than your typical desktop filament printers, Mark Two is optimized for the company's proprietary materials that produce parts with verifiable strength and flexibility.

While ease of use is its strong point, to get the most out of your Markforged investment, employees can attend a multi-day Markforged University in person or online.

- Technology: thread (continuous fiber fabrication, CFF)

- Price: Estimated price $18,000 plus accessories and materials. For an offer, contact us at 3mgbonev@gmail.com or phone 0885636868;

- Ideal for: manufacturing (fixtures, boxes, molds, factory tools), product designers (functional prototypes), teachers (models, prototypes), automobiles (spare parts, prototypes)

Raise3D Pro3 Plus

The series Pro3 finely detailed, high-speed 3D filament printers from Raise3D are mini-factories from the ground up with quality construction and reliable output print after print. It's not exactly plug-and-play, but given the complexity of its output, relatively little plug-in is required for great results.

Raise3D calls its printers "industrial grade," which fits this production tool well given its strong focus on durability, repeatability, and volume production. The large format of Pro3 Plus is preferred by artists and engineers for large (605 mm high) prints.

Pro3 Plus connects to Raise3D's 3D printing software ecosystem, which includes a 3D slicing program, ideaMaker, an open software template called ideaMaker Library, and the cloud-based 3D printing software RaiseCloud. This network capability creates a seamless workflow across the company, allowing employees in different departments to easily design files for 3D printing and produce accurate results. RaiseCloud 3D print management software remotely monitors the entire print output of one or multiple 3D printers.

A wide range of materials – from carbon fiber to wood filler – make almost any type of print possible on the Pro3.

Doing Pro3 Plus even better is the launch in 2022 of a suite of hardware, software and materials that accelerate printing. Raise3D says its new Hyper-FFF kit ($999) enables the 200% faster prototyping and print times reduced by the 75%.

- Technology: filament (fused deposition modeling, FDM)

- Price: Estimated price $7,600 plus accessories and materials. For an offer, contact us at 3mgbonev@gmail.com or phone 0885636868;

- Ideal for: product designers (rapid prototypes, functional prototypes), manufacturing (fixtures, boxes, molds), teachers (models, prototypes), cars (spare parts, prototypes)

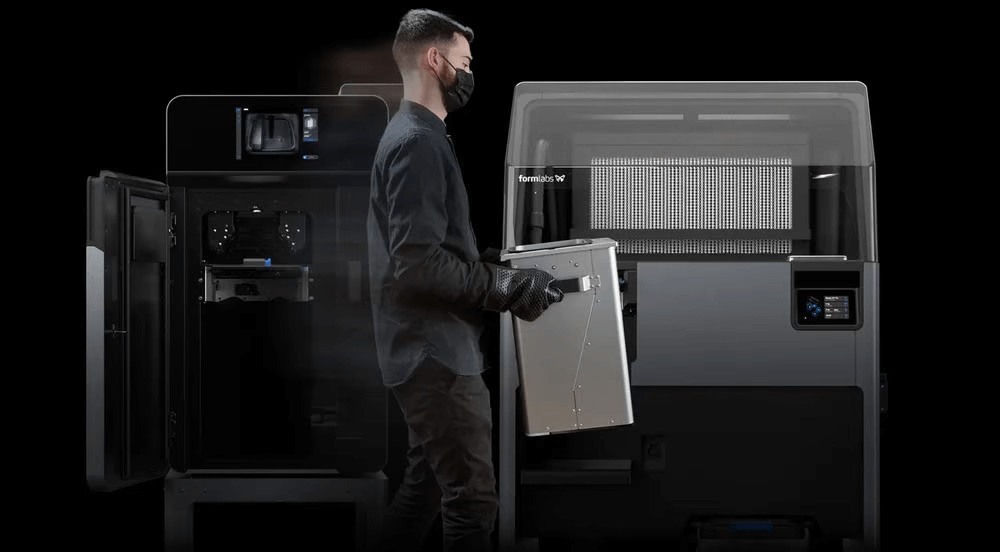

Formlabs Fuse 1+ 30W

Formlabs is best known for its resin technology, but when it finally introduced its selective laser sintering (SLS) technology in 2021, it was a game-changer not only for the company, but also for the availability of the technology. Fuse 1 is much more affordable than other SLS machines that use lasers to sinter polymer powder into 3D form, yet offers the same predictability, ease of use and quality as the company's popular resin machines.

Recently, Formlabs introduced a more powerful version of the Fuse 1, named Fuse 1+. The new machine is faster and can make strong, durable parts from carbon-filled nylon, which more and more companies are turning to for 3D-printed end-use parts.

For any small business suffering from raw material shortages, supply chain disruptions or factory closures, Fuse 1+ represents the ability to bring end-to-end and spare parts manufacturing and prototyping in-house, whether for nonstop options, validation stages, or customization applications.

As with all machines on our list, Fuse 1+ is with all the necessary post-processing accessories, materials, software, training and support to ensure that your adoption of SLS 3D printing actually solves your business problem and does not become a problem in itself.

SLS technology has been the technology of choice once a company has "got the hang" of FDM or resins. More often today, with new desktop machines like the Fuse, companies can dive into SLS without prior 3D printing experience. SLS prints are stronger than FDM prints and are more commonly used for final products and functional prototypes that can be sent to work in harsh environments.

- Technology: Powder bed fusion (selective laser sintering, SLS)

- Price: Estimated price $27 500 plus materials. For an offer, contact us at 3mgbonev@gmail.com or phone 0885636868;

- Ideal for: manufacturing (gadgets, tools, molds, end-use products), product designers (functional prototypes), teachers (models, prototypes), automobiles (spare parts, prototypes)

0 Comments