Source: UltiMaker

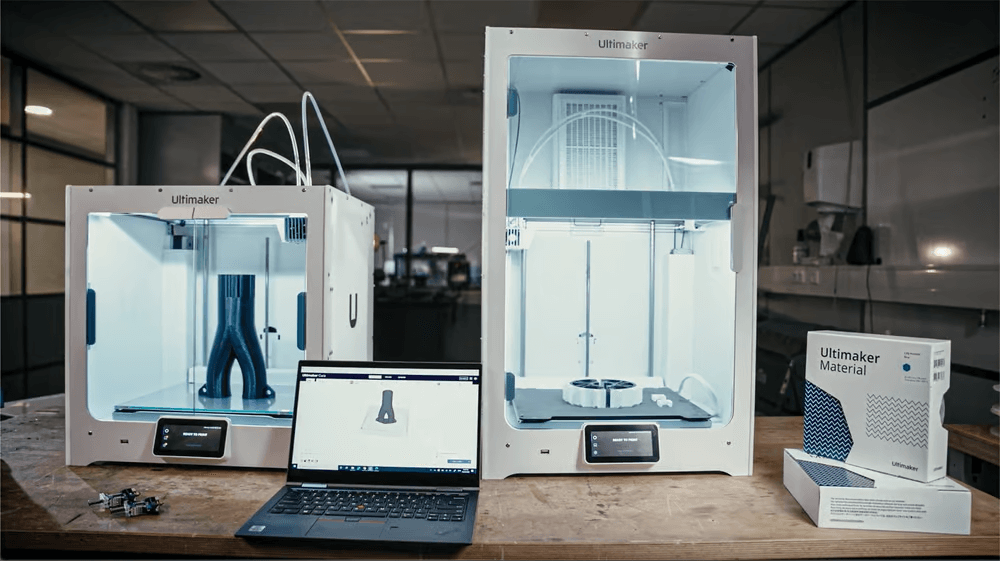

Exclusive interview with UltiMaker CTO reveals the innovation behind the company's updated flagship FDM 3D printer.

If you've just plunked down $10K on a new UltiMaker S5 Pro Bundle desktop 3D printer and are bummed that you didn't know the S7 was right around the corner, don't worry; S7 is 90% S5. However, the new improvements will increase reliability and performance for power users; these professionals running their UltiMaker workhorses 24/7 to produce parts and products critical to their businesses.

The lack of groundbreaking new improvements might be a letdown from any other printer manufacturer, but UltiMaker has already offered a very solid desktop machine. The S5 did not need a major overhaul and is not being replaced by the S7.

"In the S line, we wanted to introduce a new top-of-the-line machine that would bring improvements and reliability improvements that would have a real impact on the professionals who use this machine as a workhorse," Miguel Calvo, UltiMaker's Chief Technology Officer, in an interview with All3DP.

Customer wish lists and user-driven improvements

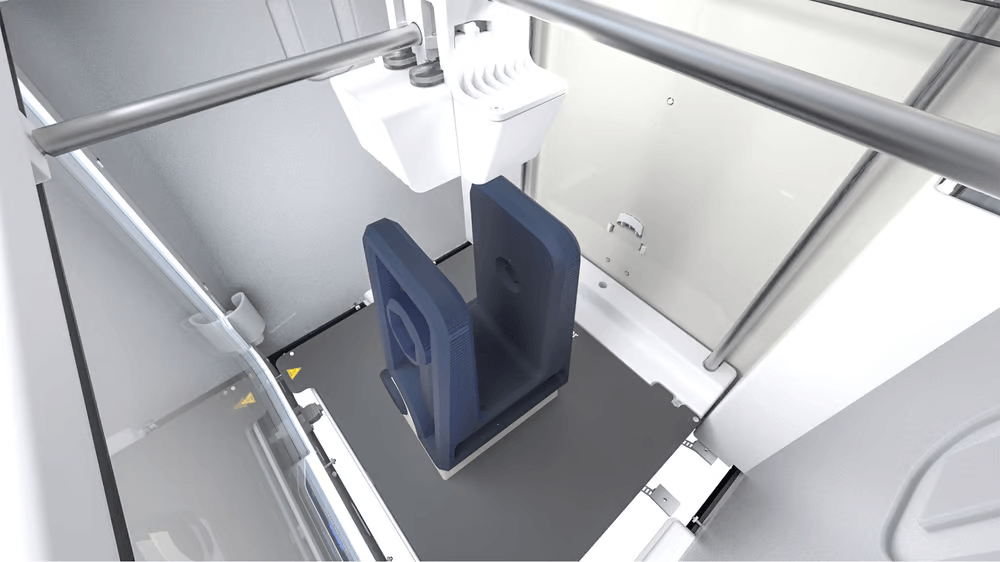

UltiMaker says the S7 includes features that customers have requested, such as a flexible build plate. Previously, UltiMaker only offered a glass plate, which was prone to breakage. The flexible built-in plate option should make removing parts significantly faster.

But underneath the build plate, UltiMaker added new technology that improves leveling and temperature consistency, both critical to achieving tight tolerances and part quality.

The temperature throughout the build chamber and on the bed itself is improved by the new build plate module, which includes a 5mm thick aluminum spreader with built-in magnets that not only secures the flexible build plate, but also distributes heat evenly.

The new build plate "disperses the heat better around the build surface and gives a much more consistent adhesion temperature," says Calvo. This means that when printing multiple, very small parts or a large print area spanning a part, the plate adhesion is so secure that UltiMaker says you can throw away your adhesives.

The build plate features a new proprietary PEI coating that UltiMaker developed with its supplier just for this purpose. It is designed to combat peeling and warping of corners and to ensure adhesion and release without the need for glue.

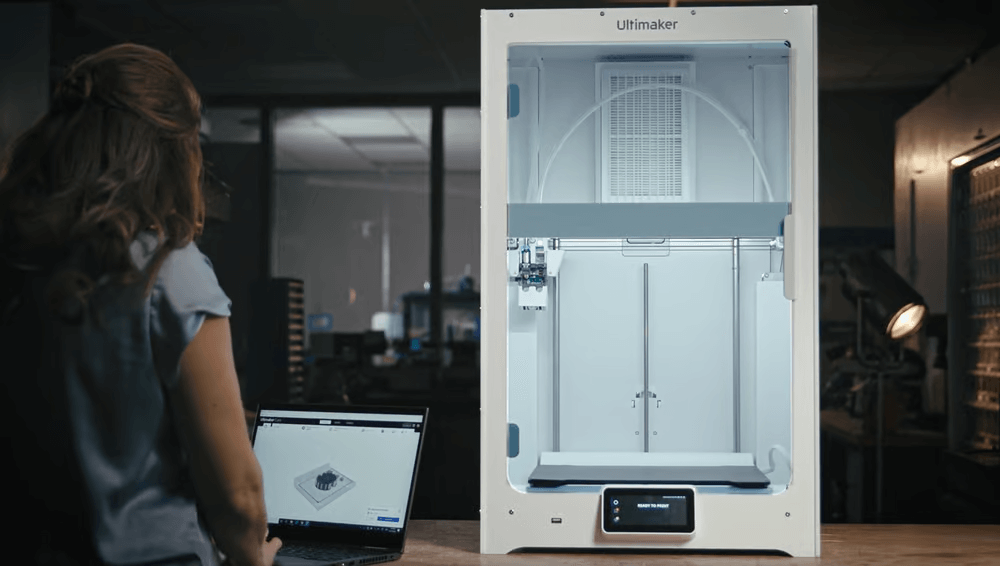

Another temperature-improving design change is the glass door. The UltiMaker ditches the S5's signature double-door design for the S7's single door, a change that Calvo says eliminates cool air that can be drawn between the double doors.

By design, the S7 draws air through the gaps around the door. This air is passively heated by the build plate and then moves up through the printer chamber. The central gap between the glass doors of the S5 will allow the air manager to draw in cool air facing the center, which when printing with a very temperature sensitive material such as ABS, can cause warping.

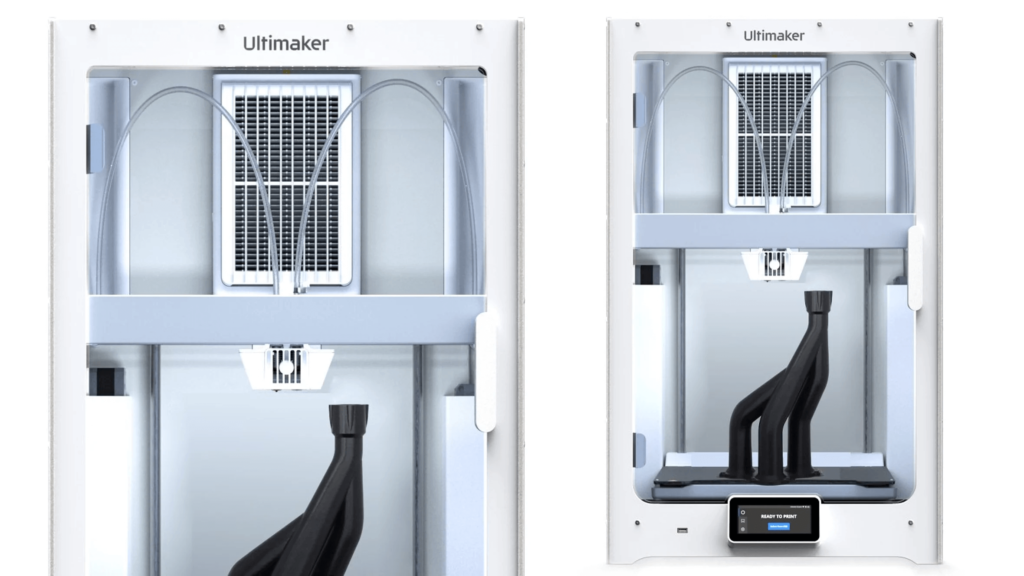

Integrated air filter

While we're talking about air, you'll notice that instead of an air filter and fan as an optional accessory, it's built into the S7, making the device look much taller. Air Manager isn't new, but fully integrating it into the camera improves its functionality, Calvo says.

Innovations in bed leveling increase tolerances

In our lab, we found the S5's automatic bed leveling to be flawless. However, UltiMaker's improvements promise an even better alignment with the S7.

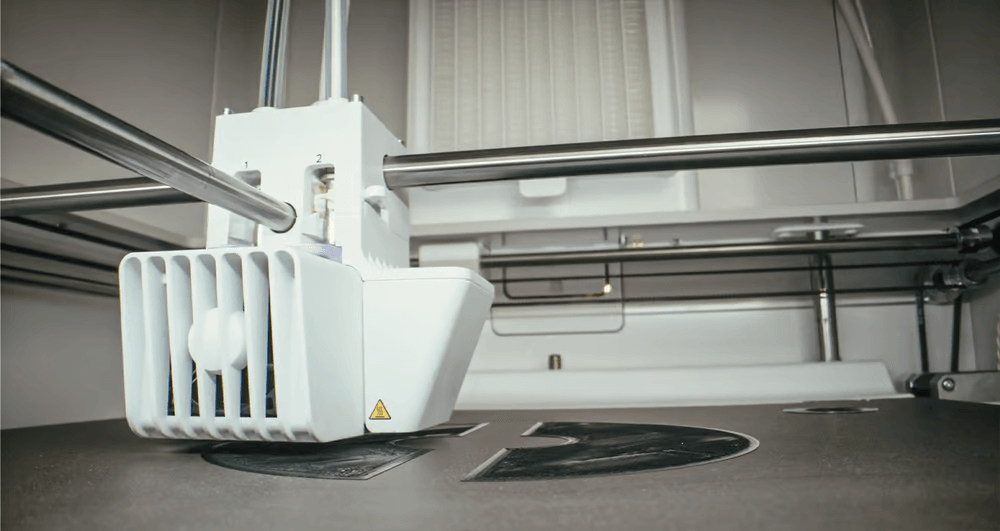

"Automatic bed leveling has a brand new algorithm that works on top of the old one," says Calvo. It still has the same multi-point leveling process, but the updated printhead has an inductive sensor instead of a capacitive sensor.

The new sensor dramatically reduces electrical noise, enabling micron tolerance measurements when leveling the bed. A new algorithm drives "live bed tilt compensation" that prints your part perfectly perpendicular to the measured bed. In other words, when printing with the S5 and many other FDM 3D printers, there is extrusion compensation that occurs within the first layers of the print to correct any deviation from the ideal level.

"In the past, if you looked at your print at a microscale, your top and bottom surfaces wouldn't be parallel," notes Calvo. The S7's compensation ensures that it always builds your part perfectly perpendicular to the actual bed. The result of this is a much more consistent part in the Z height in terms of tolerance and accuracy.

Print head upgraded with sensors

It's not noticeable from the outside, but the S7's printhead includes several performance improvements that work in the background. We've already mentioned the new leveling sensor built into the printhead, but there's also a new fan bracket closure mechanism and sensor. This may not sound revolutionary, but the fan bracket on the S5 can open, causing a complete print failure. This would happen, for example, when the user fails to clean the camera of "incandescent spaghetti" — guilty! — and is sucked into the printhead fan.

The print head now has a sensor to stop printing and alert the user so you don't waste time printing spaghetti at night if you use the machine unattended and risk damaging the print head.

"It's all about reliability, repeatability, reducing touch time for those power users," says Calvo, "and really improving machine performance and output."

Improved camera in working camera

Another minor gripe we had with the S5 was the poor rear-facing camera, which we found wasn't particularly sharp or useful. No longer! The S7 has a higher quality camera with a better PCB perspective for remote viewing.

Any Makerbot tech in the new S7?

Ever since Ultimaker and Makerbot finalized their merger to become UltiMaker in September 2022, expectations have been high for new products that will bring together the best of these two brands. However, the S7 was in development long before the merger talks and is part of the "old Ultimaker," according to Calvo. It even carries the old logo – with a lowercase 'm.'

"When we merged, the teams from both sides came together and benefited from another set of eyes working in one area," says Calvo, who hinted that the next version of Cura's cutting software, coming soon, will include new profile developments and other upgrades that were jointly developed by the now combined Ultimaker/Makerbot teams.

Although it has been five years since the debut of the S5 machine, there has been continuous progress. Since launch, the S5 has become 20% more productive in single-material printing and 30% more productive in dual-material printing, with material compatibility increased by 25 times as a result of firmware and software upgrades.

When you factor in all the improvements since the S5 launched in 2018, the S7 is a vastly different printing experience.

PRINTER SPECIFICATIONS

- Architecture: Dual Extruder

- Technology: Fused Deposition Modeling (FDM)

- Print volume: 330 x 240 x 300 mm

- Extruders: 2, with replaceable print cores

- Nozzle diameter: 0.25mm, 0.4mm, 0.6mm, 0.8mm

- Nozzle temperature: 180-280 °C

- Heated build plate: 20-140 °C

- Min. layer resolution: 20 microns with a 0.25 mm nozzle

- Screen: 4.7-inch full-color touchscreen

- Supported files: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

- Operating noise: < 50 dB

Where to buy

Please contact us to offer you the new UltiMaker S7

0 Comments