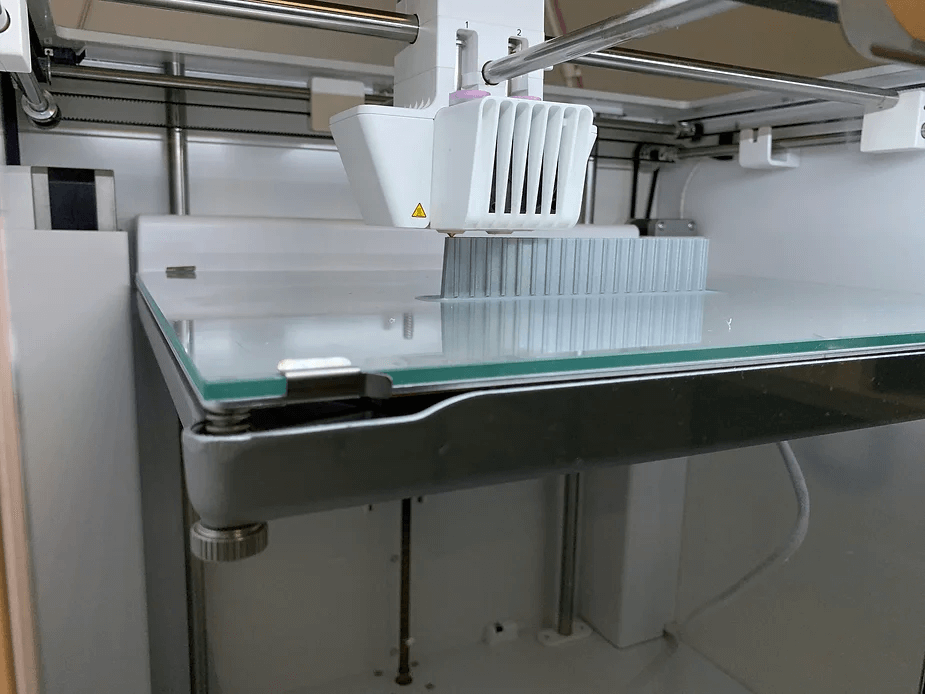

3D printing is a fascinating technology that allows you to create complex and detailed objects with the push of a button. One of the most important factors that can affect the quality and overall appearance of your printed objects is layer height.

In this blog post, we'll discuss what "layer height" is and some ways to make layer lines less visible on your 3D prints.

What is layer height?

Layer height, also known as layer thickness, is the distance between the top of one layer and the bottom of the next. In other words, it is the thickness of each individual layer that makes up a 3D printed object. Layer height is a critical factor in determining the quality and resolution of your printed object.

When the layer height is small, the printed object will have a high level of detail and a smooth surface. This is because the layers are closer together and the transition between them is less noticeable. However, smaller layer heights also mean that printing will take longer and use more filament.

On the other hand, larger layer heights will result in faster printing and less fiber usage, but the printed object will have a lower level of detail and a rougher surface. Larger layer heights also make it difficult to obtain accurate measurements and smooth surfaces.

In general, the layer height should be between 0.1 and 0.3 mm for most objects. If you are printing an object that has small details or that requires high accuracy, it will be better to use 0.1mm layer height, while if you are printing a large object that does not need to be super detailed, 0.3mm layer height is preferable. Keep in mind, however, that the best layer height for your project will depend on your specific needs and requirements.

Ways to reduce layer visibility

1. Decrease the height of the layer

One way to reduce the visibility of layer lines is to reduce the height of the layer. As the layer height decreases, the layer lines become less visible. This is because there are more layers of plastic being printed, making the transition between layers less noticeable. However, reducing the layer height will also increase the total print time and may make the print weaker. So it's a trade-off between layer line visibility and overall print quality.

2. Use a small diameter nozzle

Another way to reduce layer lines is to use a smaller diameter nozzle. Using a smaller nozzle will allow for more precise printing and reduce the visibility of layer lines. This is because a thinner nozzle will deposit less plastic per layer, making the lines less visible.

3. Adjust the temperature of the extruder

Extruder temperature can affect the visibility of layer lines. The extruder temperature should be set to the recommended temperature for the filament being used. If the temperature is too low, the plastic may not flow properly and cause visible layer lines. If the temperature is too high, the plastic can "run" and cause visible lines in the layer. Using a temperature tower model to calibrate each type of material can help improve the appearance of your 3D prints.

4. Increase print cooling

Using a cooling fan can also help reduce the visibility of layer lines. A cooling fan helps solidify the plastic as it is extruded, reducing the amount of warping and shrinking that can occur as the plastic cools. When the plastic is cooled quickly, it hardens faster and with less warping and shrinking, which can help keep the layers more aligned.

5. Slow down!

Slowing down the print speed can also help make layer lines less visible. When the print speed is slowed, the plastic has more time to harden before the next layer is added, making the layer lines less visible. However, slowing down the print speed will also increase the total print time.

6. Avoid overextrusion

Overextrusion occurs when too much plastic is extruded, which can cause spots, imperfections, or misaligned layers. To correct overextrusion, try adjusting the flow rate, extruder temperature, and retraction settings. These settings affect the amount of material pushed through the nozzle.

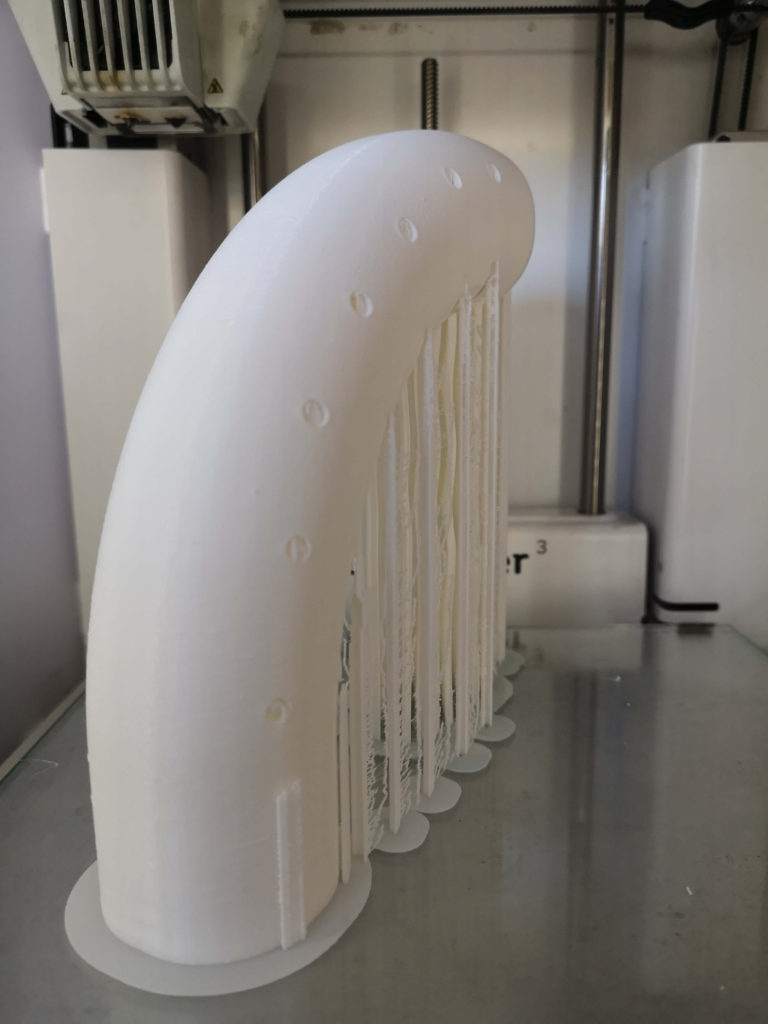

7. Correct mechanical problems

It's also worth noting that mechanical issues with the 3D printer can result in more visible layer lines. Slack in moving parts such as belts and pulleys or strong vibrations can reduce the quality of your print. Dirty or clogged nozzles can also cause the plastic to extrude unevenly. Regular maintenance and calibration of your printer can help prevent mechanical problems.

8. Use high quality thread

Thread quality can also affect the visibility of layer lines. Using a high quality filament can help reduce the visibility of ply lines by ensuring that the filament is of consistent diameter and has minimal variation in properties. This consistency allows for better control of flow rate and temperature, which can help reduce the visibility of layer lines. High-quality thread is also less likely to have defects such as bubbles or knots.

9. Monitor temperature fluctuations

Ambient temperature fluctuations can affect the plastic as it is being extruded. When the temperature varies, it can cause the plastic to expand or contract, which can affect flow rates and ply alignment, resulting in visible ply lines. Try to keep the printer in a room with stable temperature and humidity. Using a camera or enclosure is ideal.

Conclusion

Visible layer lines can detract from the overall appearance of your printed object. However, by using the techniques discussed in this post, you can reduce the visibility of layer lines and improve the overall quality of your 3D prints.

Choosing the right layer height for your project is the first step. This will depend on your specific needs and requirements, but generally a layer height between 0.1 and 0.3mm is a good starting point.

Regularly maintaining and calibrating your printer, using high-quality filament, keeping the print area at a constant temperature, and adjusting the flow rate and retraction settings can also help reduce visible layer lines.

With a little experimentation and attention to detail, you can achieve 3D printing with minimal visible layer lines and enjoy the best of your 3D printing projects.

0 Comments