Nylon is a strong and versatile 3D printing material, ideal for a wide range of professional applications. Learn how to get the most out of it.

The nylon you know

Things made of strong and durable nylon (also called polyamide or PA) are all around you. It's what makes your car's air vents and intake manifolds durable and lightweight, makes artificial turf durable for season after season of pro football, houses most of our electronic devices, and is used to make everything from skateboard wheels to factory speeds.

Since manufacturers have been making products from nylon for nearly 100 years, it is a familiar material for 3D printing. All the well-known characteristics of nylon are available when you 3D print with it.

Features of nylon:

- Endurance

- Flexibility

- Chemical resistance

- Impact resistance

- Lightly absorbent (facilitates painting)

- Resistant to sunlight

- High melting point

- Abrasion resistant

- Lighter than metal

- Electrically insulating

There are dozens of nylons

Nylon is not just one material. There are numerous categories of nylon, and within those categories there are different formulas, blends, and brands—and we're only talking about the nylons available for additive manufacturing.

3D printing nylons come in filament and powder form (sorry, no SLA resins) and more types enter the market every year. There are "full" nylons that are "infused" with carbon fiber, glass, or Kevlar; recycled and composite nylons; and a new group of more sustainable nylons designed to replace today's non-biodegradable versions with plant-based options. Today, nylon is a $22 billion market.

Here we will look at PA for FDM printers. Let's start!

Fused Deposition Modeling (FDM)

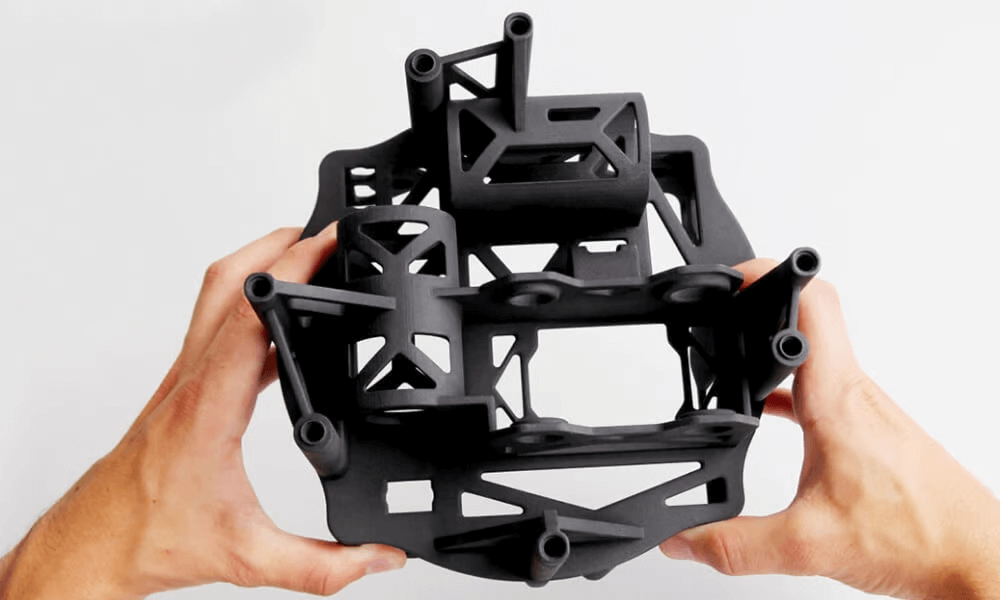

FDM (filament 3D printing) is less suitable for nylon than SLS, but still produces strong and durable parts. FDM actually has advantages over SLS, including lower cost and less mess.

FDM 3D printers use filaments that are melted and then extruded through a nozzle onto the platform to build layers until the part is complete. Not all FDM printers can handle nylon filament with ease. It is important to have a quality (all metal) hot end that can withstand temperatures above 250 °C. Additionally, nylon is also prone to warping, so bed adhesion is a problem in itself.

Nylon thread comes in different varieties, the most common being PA 6 and PA 66. Both have the standard nylon properties of strength, abrasion resistance and low friction coefficient, but come with one major drawback: high moisture absorption, so proper storage is key to successful printing.

Nylon thread can begin to degrade within a few hours if left outside of a plastic airtight container. If it's too late and your spool has already absorbed too much moisture, you may be able to save it if you dry your thread properly.

Once you've figured out the storage location, it's time to start printing with nylon filament. While it always depends on the exact printer and material you're using, and you should always keep the manufacturer's recommended settings in mind, here's an overview of the basic settings for printing on nylon:

- Nozzle Temperature: 240-290 °C

- Bed temperature: Up to 65 °C

- Bed surface: PVA glue, Magigoo, Garolite, 3DLac

- Printing speed: 25-50 mm/s

- Fan speed: 0-50%

- Body: Recommended but not required

Order nylon parts

If you're just getting started with 3D printing with nylon, ordering a few parts from a third-party 3D printing service is a great way to evaluate whether the material meets your needs.

There are hundreds of 3D printing services around the world, but if you don't have time to shop around and want the best and most reasonable price, contact us. 3MG Bonev Ltd. if it cannot provide you with the 3D service with the technology you prefer, it connects with partners and gives you a choice of the technologies and coatings you want.

We are expecting you!

0 Comments