Some designs are too large for 3D printing at once. So the parts need to be glued together. Check out some of the best adhesives for PLA, ABS and PETG!

There may be a number of reasons why you want to connect two or more 3D printed parts. The most obvious reason is when you need to print a part that is larger than your 3D printer.

However, gluing 3D printed parts can be difficult. There are several different methods: Some will result in (almost) invisible seams, while others may leave a large and ugly bump. Regardless of the method you choose, it is important that the surfaces to be glued are smooth and properly cleaned before applying the adhesive; sanding is a good way to smooth out any unevenness on the surface.

Each method has pros and cons, so it's best to review them all and choose the one that best suits your current project. Luckily for you, we've put together a list of great options!

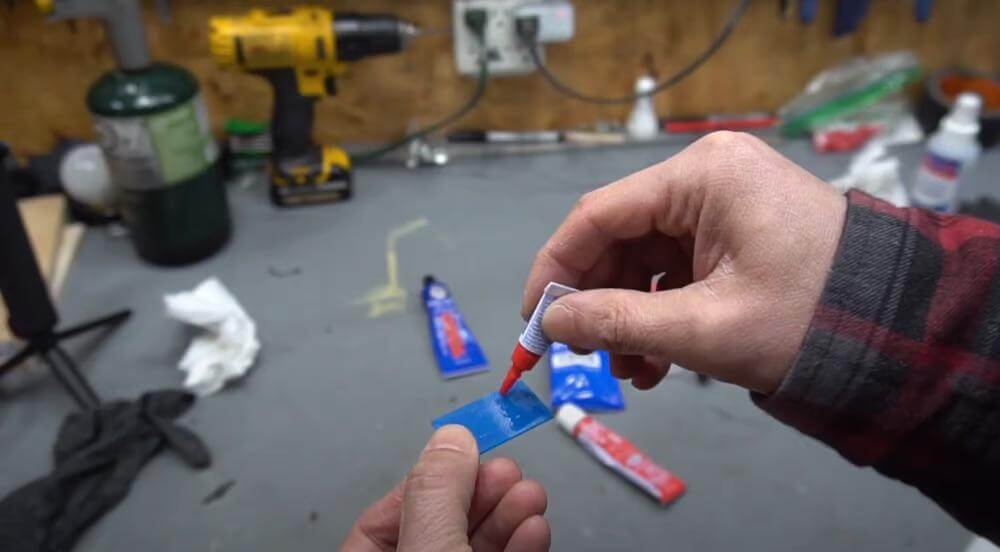

Super glue

Andrew W via YouTube)

For most tasks, cyanoacrylate or superglue is the best option for gluing 3D printed parts. This is an easy to use glue that hardens quickly. You can get excellent results, a strong connection and an almost invisible seam. As it hardens in seconds, think twice before using it and make sure you are prepared! Do your best to align the parts properly before it hardens, and hold it firmly in place for about a minute. Leave it for a few more minutes to dry completely.

Most 3D printed materials will bond successfully with superglue, except for flexible materials. When hardened, cyanoacrylate forms a thin hard layer that can easily break if applied to an elastic material.

- Preparation of the surface for gluing: If the surfaces are rough and uneven, use fine sandpaper to make them nice and flat. Thoroughly clean the surfaces with alcohol and allow them to dry. Both surfaces must be clean of all kinds of dirt, residual particles and grease.

- Suitable bonding materials: hard plastics such as ABS, PLA and PETG

- Safety: Superglue is a fast-setting adhesive, so try not to get on your skin. Use gloves to protect your hands. Work on old newspapers to protect your furniture. And of course, keep it out of the reach of children.

Acetone

Acetone or paint thinner can be used to bond 3D printed parts made of ABS or HIPS. The fact is that any material soluble in acetone is a good candidate. This type of bonding provides a very strong connection and an invisible seam.

To bond two parts with acetone, apply a thin layer of acetone on the two surfaces to be bonded. You can do this with a small brush or a piece of cloth soaked in acetone. Be careful not to use too much acetone, as there is a risk of damaging the 3D printed parts (especially if the parts are thin).

Acetone will dilute a thin layer on the surface and when you glue two pieces together, these layers will "mix". During drying, you may need to fix the pieces that are glued together with some tape or staples. After a few minutes or hours, depending on the size of the parts and the amount of acetone used, the acetone will evaporate to form a strong compact plastic layer.

This may be the best way to connect two parts made of ABS or HIPS. It is very strong and, if done correctly, is invisible.

- Preparation of the adhesive surface: Both surfaces must be cleaned of grease and dirt. Use a little sandpaper to smooth the surfaces before applying acetone.

- Suitable bonding materials: ABS, HIPS and any other materials soluble in acetone.

- Safety: Acetone is a highly flammable liquid. Use it away from open flames, sparks and hot surfaces. It is also a volatile liquid, so you should use it in a well-ventilated room or outdoors. If you feel dizzy while using it, get out into the fresh air immediately.

Epoxy resin

Epoxy resin is another great way to bond two pieces of plastic together. It will work on most threads. However, because it hardens when hardened, it may not be the best option for flexible materials. It will connect flexible materials, but you will eventually get some hard areas in your installation.

The good thing about epoxy resin is that you can use it both as an adhesive and as a filler. If there is a gap that needs to be filled or layers to be hidden, use epoxy resin.

Compared to other methods, epoxy resin requires more work to obtain a good bond. It usually comes packaged in two separate containers that need to be mixed before gluing. One is epoxy and the other contains a hardener. These components must be mixed in a certain ratio (see the instructions for use for mixing, it is different for each type of epoxy resin).

After mixing the epoxy resin well, apply it to the surfaces to be bonded. Attach all the parts you want to connect and fix them properly. Depending on the mixing ratio and the type of epoxy resin, curing can take from a few minutes to several hours.

When hardened, the epoxy resin can be sanded and painted.

- Preparation of the surface for gluing: In the case of epoxy resin, the bonding surfaces must not be completely flat. It can also be applied in quite thick layers.

- Suitable bonding materials: All materials, but epoxy resin will leave a hard seam on flexible materials.

- Safety: Read the package leaflet safety instructions and instructions before use. Some types of epoxy can become very hot during mixing.

Polyurethane and silicone adhesives

PU (polyurethane) and silicon adhesives are very easy to use and create a very strong bond. The disadvantage of both types is that they need a thickness of at least a few millimeters for proper bonding. This makes it difficult to hide the connecting seams.

Silicone glue takes several hours to harden completely, so make sure your parts are properly fixed until it hardens. On the other hand, some types of PU adhesives harden to their initial strength in seconds.

There are hundreds of types of silicone and PU adhesives on the market, each with different characteristics. It would be wise to test your chosen one before you decide to stick the parts of your model that you have spent in 3D printing in the last few days.

- Preparation of the surface for gluing: Clean both surfaces to remove any contaminants.

- Suitable bonding materials: All materials.

- Safety: Do not allow this glue to touch your skin.

Hot glue gun

The classic hot glue is an easy alternative to gluing 3D printed parts. It is important to note that as long as the bond is quite strong, the applied hot glue will be visible. Hot glue requires at least 2 to 3 mm thick, so you should take this into account when designing parts for 3D printing.

The good thing about hot glue is that it cools down in a few seconds, so you don't need to fix the parts together until they dry.

Alternatively, consider using a hot glue gun with 3D printed PLA rods. This method of gluing 3D printed parts will give you a very strong bond and the ability to match both color and material. It is ideal for PLA prints.

- Preparation of the surface for gluing: Clean both surfaces to remove any contaminants.

- Suitable bonding materials: All solid materials (ABS, PLA, PETG, etc.).

- Safety: Hot glue (or PLA) is hot. Do not burn yourself.

3D pen

A nice result can be obtained with 3D pens. The parts associated with 3D pens look as if they were printed in one piece, because the "glue" is the same thread used to print the pieces. Unfortunately, the connection is not very strong, so this technique is only good for non-functional parts.

It is important to consider the type of thread used. Both the 3D printed parts and the filament of the 3D pen must be of the same material.

- Preparation of the surface for gluing: Clean both surfaces to remove any contaminants.

- Suitable bonding materials: All materials, but you need to match the thread of the 3D pen with the material of the parts to be connected.

- Safety: The thread coming out of the 3D pen is hot.

In the lines so far, we have indicated the relatively easy ways to glue. Of course, we are not completely comprehensive and comprehensive. One of the methods I use is "welding plastics", but it requires more equipment and dexterity. The advantages it gives for specific projects are worth mastering this technique, but for more information come to our office / workshop in Yambol, 14 George Papazov Str., Office 407.

0 Comments