More and more makers are using 3D modeling and printing to design small-scale manufacturing products. A consumer story for 3D printing at home.

3D modeling and printing are used more and more in the field of functional design. Being able to produce something in a CAD program (like SolidWorks) and then print a physical 3D model gives designers and manufacturers a better sense of how the final product will look in physical space.

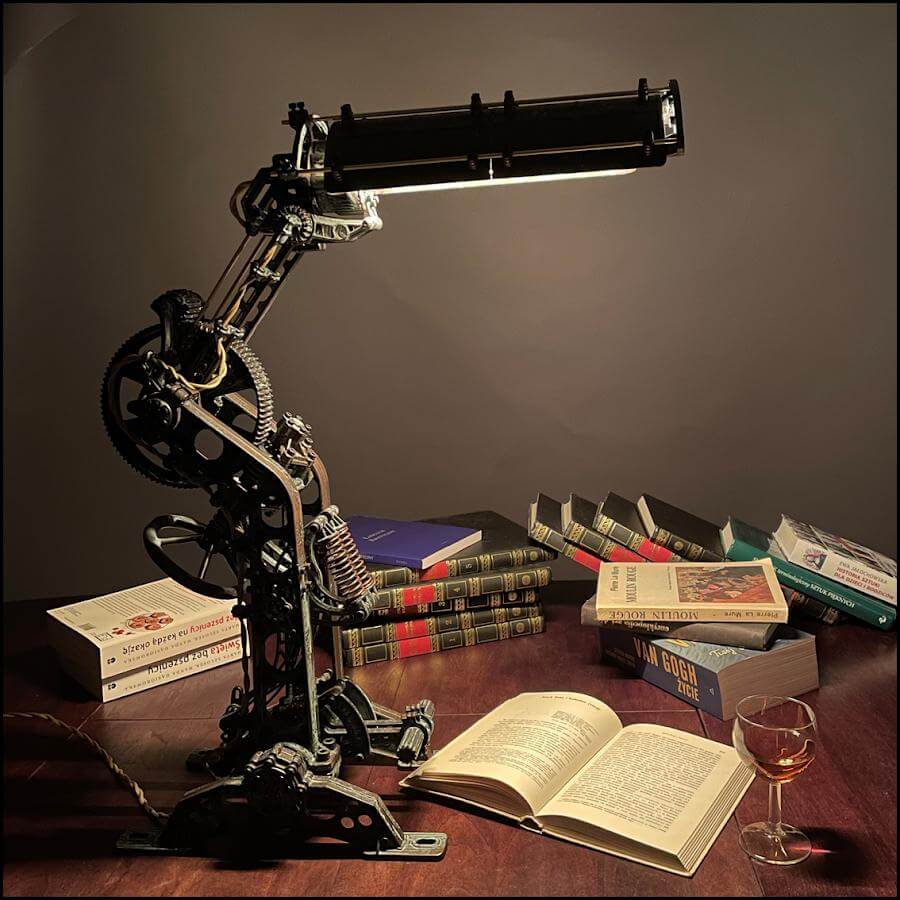

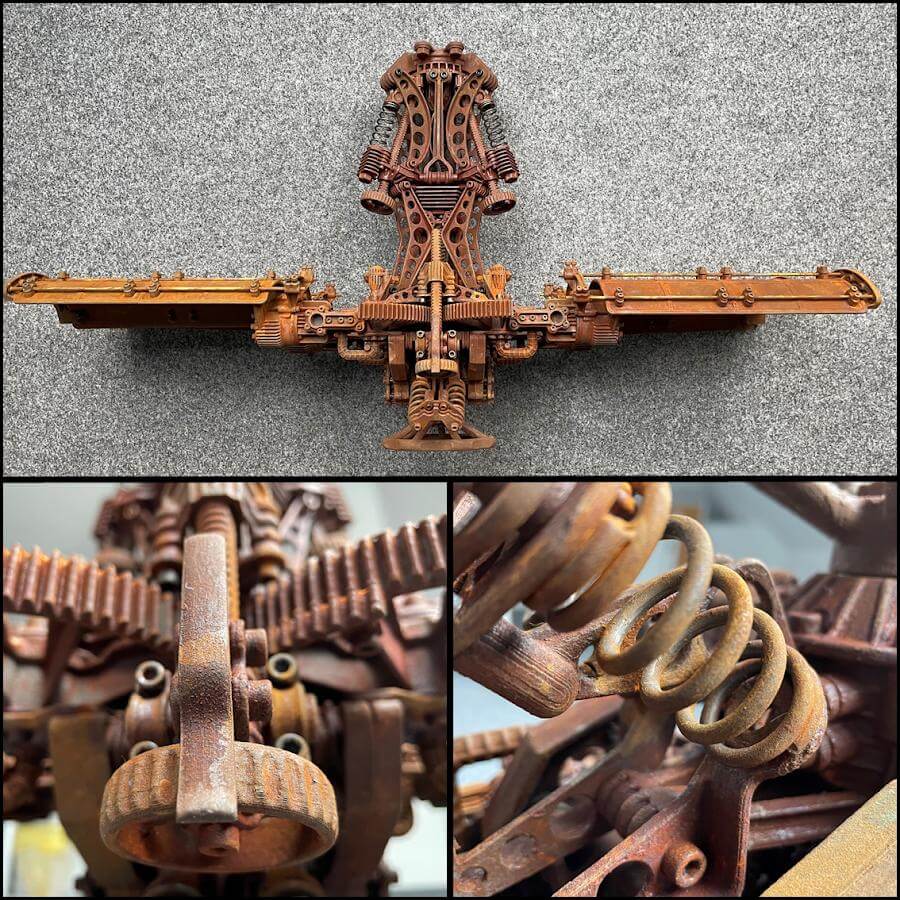

Tomasz, a longtime 3D designer from Warsaw, Poland, who has been using SolidWorks for nearly 20 years to design and manufacture items for the medical, automotive, IT, and other industries. He currently designs steampunk-style lamps for his own thriving startup company, which was recently successfully funded on Kickstarter.

Tomasz has seen firsthand how the capabilities and adoption of 3D modeling and 3D printing have enabled their use in all of these industries. “The widespread use of 3D printing has made it much easier and faster to bring products to market. It is easy to print several variants of a product and evaluate its ergonomics and other parameters already at the initial concept stage. The companies I work with value this opportunity.”

The two main points for any industry looking to adopt 3D printing in their prototyping workflow are the time from concept to production, and the time to execute iterations to the final product. 3D printing dramatically reduces the time and money spent on manufacturing new products and modifying existing ones. Some industries have seen over 90% reductions in the time and money required to bring a product to market after adopting 3D printing.

It also opens up the opportunity for "ideas on the fringes" to get more attention and a greater opportunity to create. “I have completed many industrial design projects for companies in the medical, automotive, IT and other industries. Each of these implementations is 3D printed using FDM or SLA technology. Sometimes these were short runs intended for inspection by a larger team. I think that without the possibility of 3D printing, many of these projects simply would not have been created.

With the cost of 3D printing resulting in such a low development cost, even these smaller, previously rejected ideas are becoming more and more realized. The designs Tomasz creates for his Steampunk lamps simply wouldn't be possible without 3D printing locally.

“Without the ability to 3D print designs and assemble them, my hobby would not exist. Making CAD designs is not as satisfying as being able to assemble and use them, so these are lamp designs that combine creativity and functionality.”

Because the costs in the design process for each stage have been reduced so drastically, there are more and more opportunities for small and medium-sized companies to become relevant in a market that would otherwise be inaccessible to them due to the huge initial cost of machines to produce products in the traditional sense of the word. By bringing everything in-house for the iterative development and manufacturing process, manufacturing and prototyping costs are no longer a barrier to entry for these new, innovative companies.

3D printing has helped Tomasz start working on projects that interest him instead of working for a larger company—all without a huge investment in capital equipment. From concept research to rapid prototyping and final production, 3D printing has allowed him to bring his own visions to life and share them with a wider audience who can virtually order these designs and in turn manufacture them themselves at home. No supply chain management, no shipping fees, no giant customer service and HR overhead; everything is done on a very personal level, from design, to purchase, to 3D printing at home by the customer.

Using Kickstarter, he is able to reach a precise audience – people who are interested in new and exciting ideas in 3D printing that speak to them and their design aesthetic. Something traditional production and advertising platforms have never been able to do.

Thanks to Tomasz for sharing his story with us and allowing us to share his work for this article. 3MG Bonev Ltd. we have many more resources available to anyone who has ideas and is interested in how to bring their projects to life. Contact us to do it together!

You can visit Tomasz's Instagram page for more information and inspiration here: https://www.instagram.com/tomaszfortyfour/

If you have any questions about 3D printing and how to bring it into your workflow, please email 3mgbonev@gmail.com - we have the experts and experience to suggest the most suitable additive technology for your project(s).

0 Comments