Nylon is a strong and durable material. Learn the basics of 3D printing with filament and discover some of the best brands on the market.

Nylon, a branch of synthetic polymers, is a strong and durable material originally found in textiles. The technical name of the material is polyamide (PA), while the common name is "nylon” (although some still associate it with socks). The material is distinguished by its durability and resistance to high temperatures and impacts. It also has a very low coefficient of friction.

Nylon comes in several varieties that are designated by numbers. Two common ones are PA 11 and PA 12, which have strong all-purpose properties and low moisture absorption (more on that later). Between the two, PA 11 has higher temperature and UV resistance along with better flexibility. Nevertheless, both materials are most commonly used with SLS and MJF technologies rather than in filament-based processes. As such, they are largely beyond the scope of this article.

More common in filament based printing, along with manufacturing in general, are PA 6 and PA 66. Both are popular for their high processability and low cost, with PA 6 being more common in 3D printing due to its slightly more its good workability. However, these materials suffer from higher moisture absorption, which can degrade the polymers. Therefore, proper storage of the material is a must.

Printing and storage

Nylon used to be quite a challenging material to print on, but manufacturers have made it much more affordable in recent years. While you shouldn't expect it to print as easily as PLA or PETG, printability shouldn't be a barrier to use. Here are the basic print settings we recommend for Nylon:

- Nozzle Temperature: 240-290 °C

- Bed temperature: Up to 65 °C

- Bed Adhesion Surface: PVA glue, Magigoo, Garolite, 3DLac

- Printing speed: 25-50 mm/s

- Fan speed: 0-50%

- Close the printer: Recommended but not required

While these general settings should serve you well, materials vary by manufacturer. Before printing anything, it's always a good idea to check the manufacturer's recommended settings. For the brands we've listed below, we've gathered the specific information for you.

Storage

As mentioned, proper storage of nylon is critical. The variants used in 3D printing are extremely hygroscopic, meaning they absorb moisture. This moisture degrades the material and results in poor print quality and strength.

To avoid problems with wet threads, store the thread in a dry environment. Because nylon can deteriorate in even a few hours, we also recommend printing directly from a humidity-controlled container. This can be a dry box with a thread feed hole or a humidity controlled spool holder.

If your nylon picks up some moisture, you will need to dry your thread.

With that said, we are ready to get into the best nylon brands!

Ultimaker Nylon

Another copolymer of PA 6 and PA 66- Ultimaker Nylon is a premium thread. It offers solid all-round performance and is tuned for lower moisture absorption. Ultimaker 3D printer and Cura slicer users will also benefit from integration into the Ultimaker ecosystem.

For those with Ultimaker's S5 Pro bundle, demanding nylon storage requirements can be solved with the Material Station.

- Nozzle Temperature: 230-260 °C

- Bed temperature: 60-70 °C

- Bed Adhesion Surface: PVA glue, Magigoo PA

- Diameter: 2.85 mm

- Colors: Black, transparent

ColorFabb PA clear

PA Neat from premium filament manufacturer ColorFabb boasts similar characteristics to Polymaker's PolyMide CoPA. Also tuned for low distortion, it is able to survive extended use at 120 °C while maintaining mechanical properties. The tensile strength is also slightly higher than PolyMide CoPA.

Note: This thread is stiff, so ColorFabb recommends that users of 2.85mm threads use a spool mount with some friction between the spool and the spool holder to prevent unwinding.

- Nozzle Temperature: 265-290 °C

- Bed temperature: up to 50 °C

- Bed Adhesion Surface: 3DLac

- Diameters: 1.75mm, 2.85mm

- Color: Black

ColorFabb PA-CF Low Warp

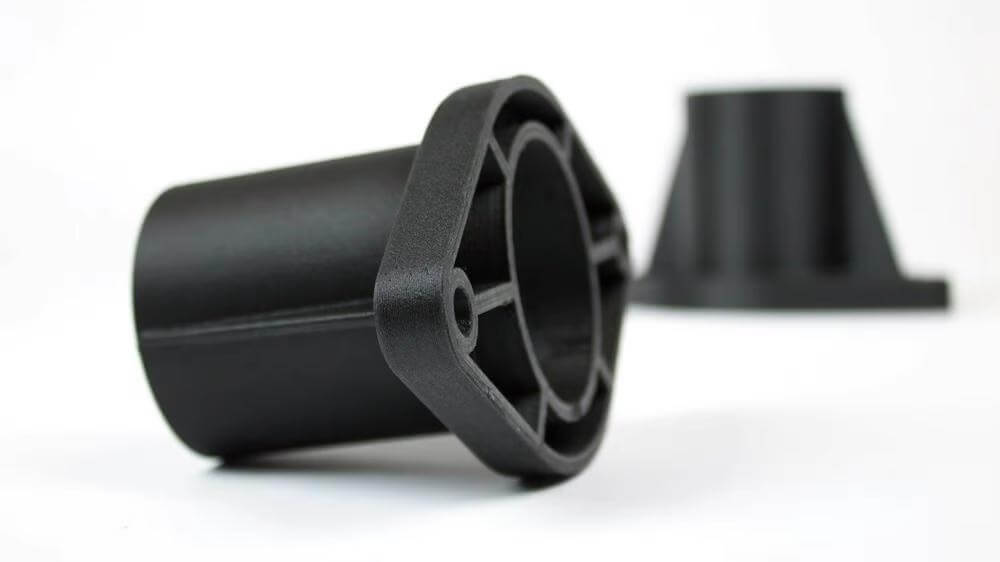

ColorFabb PA-CF Low Warp has many of the benefits of ColorFabb's PA Neat; it also prints with almost no warping and features a continuous operating temperature of 120 °C. What it has over the PA Neat is the addition of carbon fiber. They dramatically increase the stiffness and tensile strength of the material, making it ideal for parts that need to be strong and hold their shape.

Note: Like PA Neat, this thread is stiff, so ColorFabb recommends that users with 2.85mm thread use a spool mount with some friction between the spool and the spool holder to prevent unwinding.

- Nozzle Temperature: 260-280 °C

- Bed temperature: up to 50 °C

- Bed Adhesion Surface: 3DLac

- Diameters: 1.75mm, 2.85mm

- Color: Black

Polymaker PolyMide CoPA

A copolymer of PA 6 and PA 66, Polymaker PolyMide CoPA is designed with both printing and performance in mind. It features spectacularly low distortion while softening at just an impressive 180°C. This unique combination of features makes printing for demanding applications significantly easier.

- Nozzle Temperature: 250-270 °C

- Bed temperature: 25-50 °C

- Bed Adhesion Surface: PVA glue

- Diameters: 1.75mm, 2.85mm

- Colors: Black, natural

Nylon Composites by MatterHackers

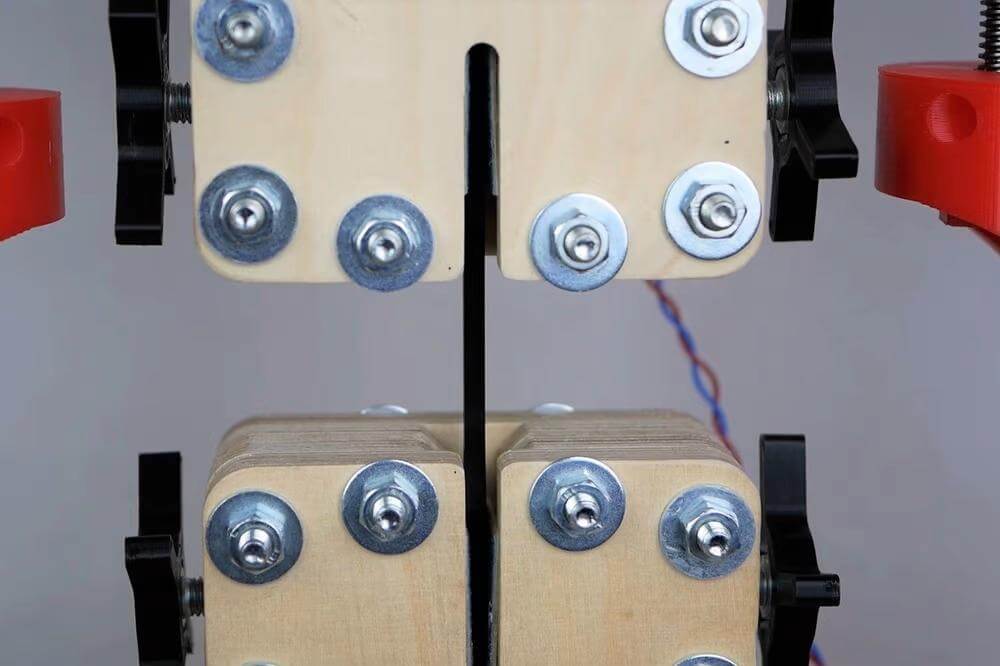

Here we have Matterhacker's high performance line of nylon composites. These three threads are impregnated with various other materials for specific properties and applications: NylonX has carbon fibers for stiffness and strength, NylonG has glass fibers for impact resistance, and NylonK has Kevlar fibers for abrasion resistance. Depending on what you need, you can choose the right material with the right properties for a range of demanding applications.

MATTERHACKERS NYLONX

- Nozzle Temperature: 250-265 °C

- Bed temperature: 60-65 °C

- Bed Adhesion Surface: PVA glue

- Diameters: 1.75mm, 2.85mm

- Color: Black

MATTERHACKERS NYLON

- Nozzle Temperature: 245-265 °C

- Bed temperature: 65 °C

- Bed Adhesion Surface: Garolite, Magigoo

- Diameters: 1.75mm, 2.85mm

- Colors: red, orange, white, blue, olive green, silver, desert tan

MATTERHACKERS NYLONK

- Nozzle Temperature: 250-265 °C

- Bed temperature: 60-65 °C

- Bed Adhesion Surface: PVA glue

- Diameters: 1.75mm, 2.85mm

- Color: Black

0 Comments