Copper is one of the newest and most promising areas of metal 3D printing for everything from electric motors to radiators.

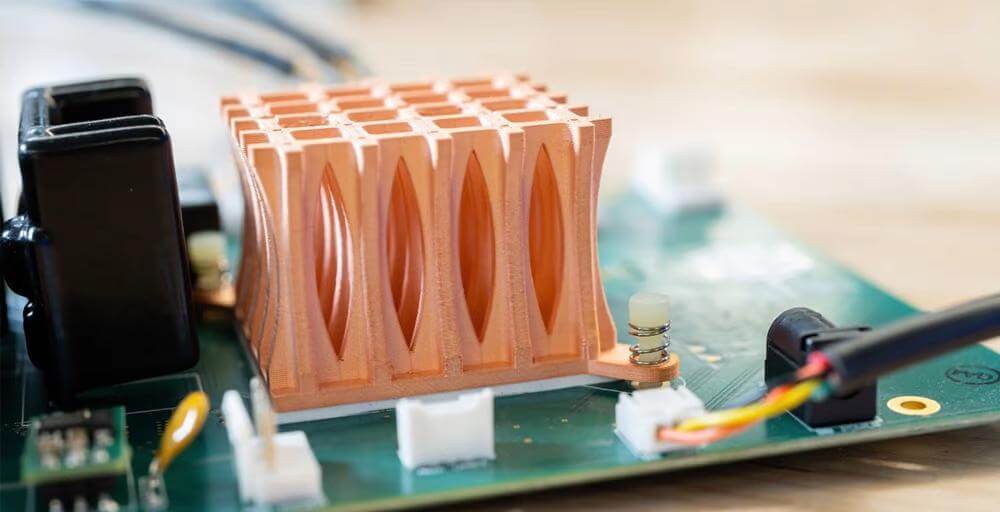

Earlier, 3D printing with copper was a challenge due to the reflectivity of the metal and high thermal conductivity, but advances in printers and materials have largely met these early challenges. Today, 3D-powered copper-powered systems send rockets into space, 3D-printed copper heatsinks keep processors cool, and 3D-printed copper-coiled coils increase motor performance.

Why 3D printing with honey?

Copper has always been an extremely useful metal due to its ability to conduct heat and electricity, resist corrosion and even kill bacteria and viruses. Demand for sophisticated copper parts is growing as 3D printing opens up even more applications and opportunities for this metal.

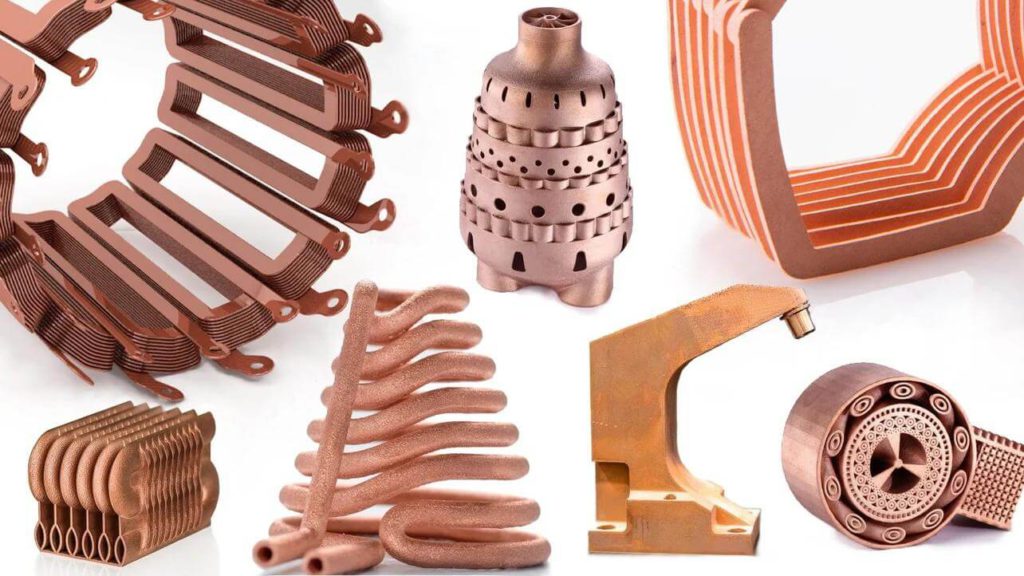

3D printing (also known as the production of additives) allows the production of extremely complex shapes, fine details, internal structures and lattice fillings, which are not possible in other types of metal production. These features reduce weight, increase efficiency and reduce production and assembly time, as multi-component assemblies can be 3D printed as a whole.

3D printing also allows more efficient production of this relatively expensive metal, reducing waste, as it uses only the required amount of material for each part. For companies interested in 3D copper printing, reducing the cost of raw materials is crucial.

If you already produce custom copper parts, you may be able to drastically reduce production costs while optimizing the performance of 3D printing parts.

Read on to learn more about technologies and 3D printers that enable engineers, manufacturers and designers to rethink what is possible with copper.

Although there are not many 3D printers that can print with honey, there is still a great variety in printing technology and price.

FDM printers using copper-filled plastic filament can produce copper jewelry, decorative items and other parts that are almost 100% copper. While for more advanced production, 3D printers that use copper powder, rods or copper and polymer slurry produce industrial parts with excellent mechanical and conductive properties that can meet international standards such as IACS (International Standard for Annealed Copper).

Let's look at the types of printers today that can handle honey.

Copper Powder Bed Fusion 3D Printers

Powder bed synthesis powder is one of the most popular methods for 3D metal printing, and several machine manufacturers have recently added copper to their list of material options. As copper is highly reflective, laser powder processing is an obstacle for manufacturers. However, this technology and materials have evolved to meet the challenge.

3D printer maker Trumpf, for example, has developed an industrial green laser that enables 3D printing of materials such as copper, copper alloys and precious metals that are difficult to process with infrared wavelengths.

Two metal 3D printing powder technologies, DMLS (direct metal laser sintering) and EBM (electron beam melting), work by spreading a thin layer of copper powder on a platform in the printer. The powder is heated while the lasers or electron beams trace the first layer of the part. As the particles in the layer merge, the platform is gently lowered into the construction chamber with fresh powder applied on top, and the process is repeated. Some of the copper powder left over from the process can be recycled for use in the next print.

3D printers with copper powder bed technology

| Brand | Printer | Material | Price (approximately ) |

| EOS | M 290 | Cu | $225,000 |

| EOS | AMCM M 290 DUAL FDR | CuCP, CuCrZr | $225,000 |

| EOS | EOS M 400 | CuCrZr | $200,000 |

| GE | Arcam EBM Q10plus | Cu | $100,000 |

| Trumpf | TruPrint 1000 Green Edition | Cu, CuCrZr | $170,000 |

| Xact Metal | XM200C | CuAlFe, CuCrZr | $125,000 |

Copper Binder Jet 3D Printers

Copper powder bonded with a liquid binder, then baked in an oven, is a 3D printing method known as inkjet binder, and it produces parts without the need for a backing. Jet bonding is a heat-free process in which a bonding layer is sprayed between each layer of metal; the binder is later removed in the sintering process.

Jet bonding is a popular method for the additive production of large volumes of metal parts.

3D printers with connecting jet with copper

Copper-Enabled Binder Jet 3D Printers

| Brand | Printer | Materials | Price (approximately ) |

| Digital Metal | DM P2500 | Cu | $275,000 |

| ExOne | X1 160 Pro | Cu | $150,000 |

| ExOne | X1 25 Pro | Cu | $100,000 |

| ExOne | Innovent + Pro | Cu | $250,000 |

| ExOne | M-Flex | Cu | $500,000+ |

Copper FDM and Bound Metal Deposition 3D Printers

The most economical approach to copper parts for 3D printing is with machines that extrude threads. The metal thread for printing metal parts consists of a plastic base with metal particles evenly embedded in it. Copper filament for copper parts is a unique type of composite filament that can give strong, chemically resistant and almost hard metal parts when used properly.

Almost any fusion model (FDM) printer can print almost hard metal parts with copper powder-filled polymer thread. Currently, one of the options on the market is from the thread manufacturer The Virtual Foundry. The company says its copper thread is printed on any incandescent 3D printer with a hardened nozzle and a hot end that can reach 225ºC. However, the parts are not exactly metal from the printing bed and require additional steps after printing to melt the polymeric binder and leave only the metal behind.

Other types of copper threads have enough real copper particles inside to be polished and have a metallic weight, but they are designed for decorative purposes.

A Chilean company called Copper3D produces a copper-filled filament that does not produce metal parts, but instead those that have the antibacterial and antimicrobial properties of copper. According to the company, NASA is even testing the thread for use in "interplanetary microbial pollution".

In addition to the main FDM printers, two others that extrude filaments also offer copper, but they use their own materials. Desktop Metal uses bonded metal thread, while Markforged uses similar metal powder that is bonded into a plastic matrix. Printers from these manufacturers produce hard metal parts for industrial use, such as machine tools, inductors, radiators and functional prototypes.

Copper FDM 3D printers

Copper-Enabled FDM 3D Printers

| Brand | Printer | Material | Price (approximately ) |

| Desktop Metal | Studio System | Cu | $160,000 |

| Markforged | Metal X | Cu | $99,500 |

Copper Cold Spray and DED 3D Printers

Although these two methods of metal 3D printing are not usually grouped together, we combine them here due to their common application for coating metal parts with another metal and building metal parts with metal powder layer by layer.

Directed energy deposition (DED) is a system developed by the New Mexico-based Optomec for the creation, improvement and repair of metal components. Like SLS, DED's powerful lasers build 3D structures layer by layer, producing high-density, high-strength parts ideal for mechanical applications. In 2019, Optomec developed a new DED process for copper for the production of heat exchangers for use in space, chemical processing and other industrial applications.

Spee3D's WarpSpee3D is unique in its process, using supersonic 3D deposition to produce parts from a range of metallic powder raw materials, including copper and aluminum.

Cold spray is a technology for the production of additives that injects metal dust into gas with supersonic pressure under pressure. Instead of melting the metal, the cold spray binds the metal together in a process called plastic deformation. Companies such as Spee3D use cold spray technology to apply antimicrobial copper coating to doors, railings and touch panels for use in hospitals, schools and other public places.

Cold spray is also the fastest method for 3D printing of metals. Spee3D prints a 17.9kg aerospace rocket with nozzles (pictured below) from pure copper on WarpSpee3D in about three hours for just $ 716, the company said. Such parts are usually made of hard forged copper in a process that takes weeks and costs tens of thousands of dollars.

One disadvantage of DED and Cold spray is that they are limited in the production of complex geometries.

3D printers for honey - Cold spray and DED

| Brand | Printer | Material | Price (approximately ) |

| Spee3D | WarpSpee3D | Cu | $160 000 |

| Optomec | LENS AM systems | Cu | $ 200 000+ |

Photopolymerization

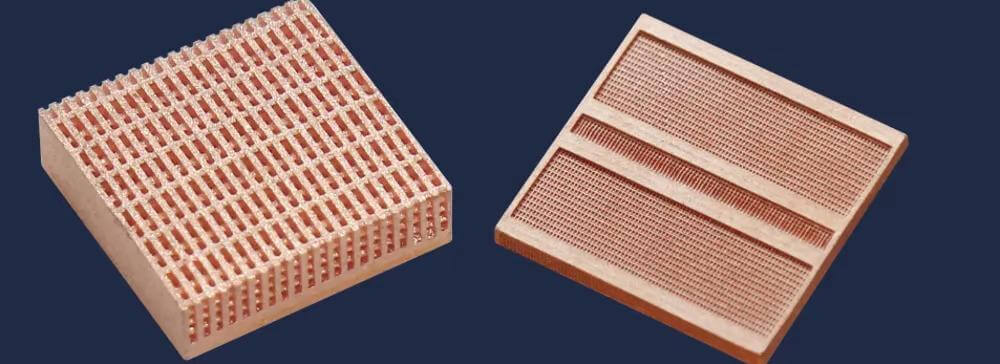

Metal DLP 3D printing is similar to 3D resin printing in that it uses UV light designed on a photosensitive suspension to harden it layer by layer. Instead of resin, metal DLP printers use a liquid polymer filled with metal powder and a small amount of binder. Once the parts are printed, they must go through more steps before the finished metal parts are ready for use. Metallic DLP 3D printing is valuable for its fine detail.

The California-based startup Holo recently completed a facility where it plans to print 3D parts of pure copper on its own non-selling 3D printers. Holo will focus on 3D printed copper cooling solutions for high-performance computers, electric vehicles, RF antennas and heat exchangers.

Admatec, a Dutch manufacturer of 3D printers, offers printers that also use copper resin to produce highly detailed copper parts.

| Brand | Printer | Material | Price (approximately ) |

| HoloAM | PureForm | Cu | Print service only |

| Admatec | Admaflex 130 | Cu | $150,000 |

We from "3MG Bonev"Ltd., as a partner company of the official representative for the Balkans, we offer some of the manufacturers listed in this article / these are the brands Markforged and EOS / - both for the region and for the whole country. Do not hesitate to contact us and ask us for more information.

0 Comments