3D printing support is often essential when working with geometrically complex model. Let's take a look at the support types as well as the settings for success!

3D printing, like everything else on Earth, is limited by gravity. Despite their incredible ability to turn spools of plastic into action figures, giant swords, and other fun models, 3D printers don't print well in air.

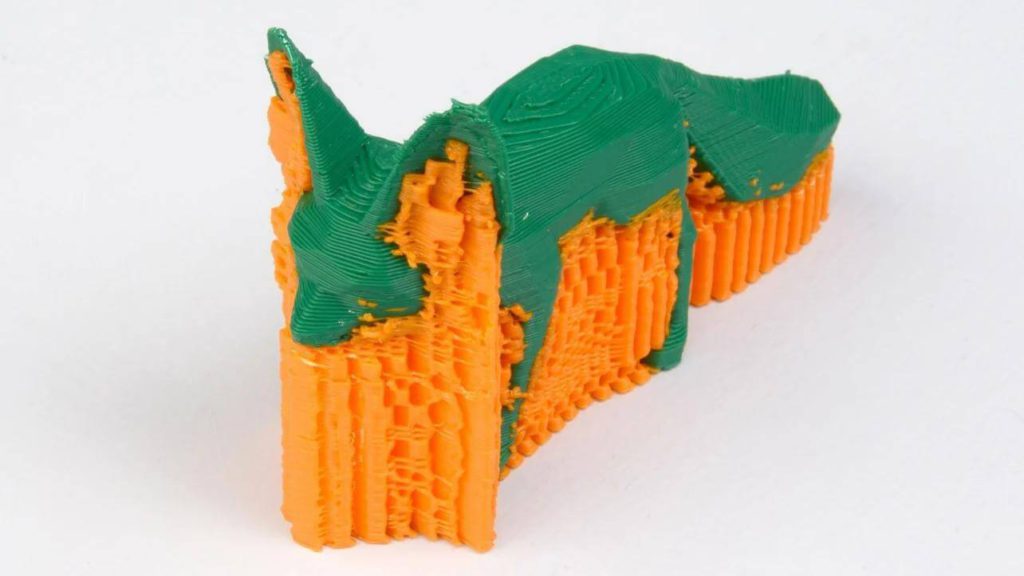

To combat this problem, the slicing software /slicer/ can add any 3D printing supports to hold your model while it prints. Once everything is printed, these supports can be removed, although they may leave their mark on the surface of your part.

In this article, we'll go through the three main steps you should follow when deciding whether and how to add supports /pores/ to your model. We'll look at the options using the Cura slicer settings as an example, although similar settings will be available in most slicers.

Step 1: When to use supports

hubs)

Not every 3D print requires maintenance, and this is something to keep in mind when preparing any model. A key aspect of props is knowing how to avoid them, as they contribute to waste and can affect the surface of your printed part.

Deciding on props

Here's how to tell if your model needs maintenance:

- Wide angle of overhangs or bridges: Overhangs are print elements for which the printer must print partially or fully in the air, such as the shoulders of theT" or "D', printed vertically. Bridges, on the other hand, are overhangs that are connected to the model at both ends, such as the middle of an "H". Overhangs and bridges are usually measured by an angle measured from the axis Z over the overhang. For example, the letter T contains an overhang of 90 degrees, while the letter Y has an overhang of 45 degrees. If you notice strong overhangs in your model (over 60 °), you probably need supports. For overhangs above 90 ° (e.g. the Arch of lowercase letters "r“) supports will always be needed.

- Printer performance: Not all 3D printers are created equal. Try printing an overhang test to see how well your printer is performing. If a 60 degree overhang doesn't look so good, you should enable supports for models with similar overhangs.

- Slow print speed: In general, lower print speeds result in better quality prints. But when it comes to 3D printing support, that's not always the case. The faster the print speed, the better overhangs and especially bridges are obtained. If you are printing something slowly, you may need to include supports for a lower overhang angle than if you are printing at higher speeds.

Avoidance of support

As they say, "prevention is better than cure". Here are some general guidelines to avoid having to print with supports:

- Orient the print correctly: As an example, let's say we want to print the letter T. If we try to print it upright, we are forced to use support for this 3D print. But if we simply rotate the model so that the "top strip" lies flat on the print bed, we don't need supports at all, saving both material and time. Make sure your model is in the best orientation to minimize 3D printed supports.

- Reduce the overhang angles: If you created the model yourself, consider editing it so that the overhang angles are reduced.

- Consider splitting the model into two parts: Spheres are one of the trickiest shapes to 3D print, as huge overhangs near the bottom tend to look pretty ugly, even with supports. In such a case, it is much easier to print two halves of the sphere separately and glue them together for a beautiful finish without supports.

- Design for 3D printing: If you can work with a model in CAD or a 3D modeling tool, it may be worth adjusting its design to suit the 3D printing process.

Step 2: Select the type of support

Ultimaker )

If you're sure you need support, in Cura (or your preferred editor) you can simply check the "Generate Support" box and go for it. Still, there are so many ways to support 3D printing that it might be worth digging into the settings.

Lattice Supports

Lattice supports are the most common type of support. They are popular because they are easy to customize, quick to generate, and work well for most 3D models. The downside is that if not printed correctly, the supports can leave marks on the finished model and be difficult to remove. In general, use lattice supports for flat, angled or very steep overhangs.

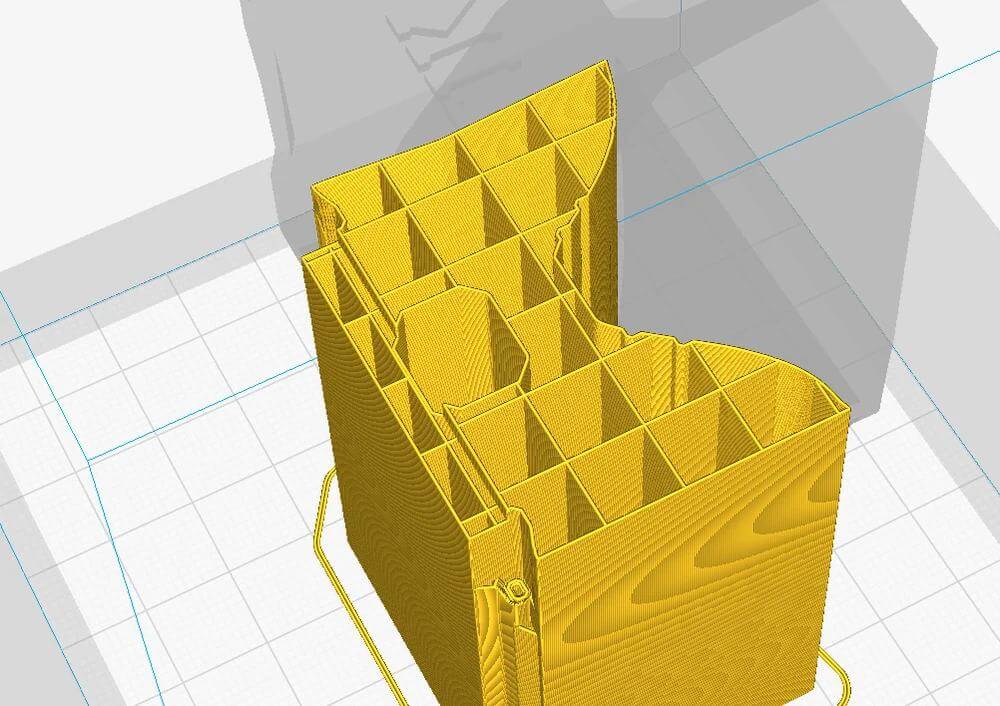

In Cura, if you don't see the option “Support Pattern" under the menu Support , set the visibility of your settings to “Advanced" or higher. Then use the drop-down menu to select your preferred support model. You can switch between X-Ray and Layer view per layer in the preview to see what it looks like.

The default support type in Cura is Zig Zag, which is reasonable as it is easy to print and remove. However, there are actually seven support templates to choose from below the detail (some of which are pictured above). Be sure to choose a prop pattern that matches the shape of your pattern. Concentric, for example, is useful for parts with circular overhangs (such as a sphere) that are not uniformly supported by a grid.

Tree Supports

Wood supports are pretty much exactly what they sound like. They start from "trunks" near the base of a print and branch out to support overhangs in the pattern as they increase in height. Tree props are most effective for organic forms such as humans and animals.

In 3D printing, these supports can save material and printing time. In Cura, select tree support using the drop-down menu “Support Structure". Make sure your model is correctly positioned and oriented before you hit 'Slice' as they can take a long time to generate!

Because wood props don't touch the model as much, they generally offer a cleaner surface. Cutting them can take a long time since the trees are generated dynamically. Choose these supports if your model has very organic shapes or overhangs that are small or not very steep (less than 60°). These supports are less effective for wide, flat overhangs, such as a roof, because they are designed to touch the model at fewer points.

Dissolving supports

This is a niche but high-quality alternative to pads printed from the same material as the model. For example, with a dual-extruder printer, one nozzle may print a model in PLA, while another prints the entire support material in a water-soluble filament (usually PVA). When the 3D printing is complete, simply soak the print in some water and the supports will dissolve, leaving a clean model behind. How cool is that? 😉

If you're lucky enough to own a twin-extruder printer and don't mind paying for a slightly more expensive filament, we definitely recommend this option.

Step 3: Set the support density

The next step is to determine the best density at which to support 3D printing. We recommend starting with a density of around 10% and then adjust to your liking. To view your sliced supports in Cura, select the “Layer view' in the section Preview and make sure that "Helpers' are marked in the color scheme. Here are some factors that affect maintenance density:

- Printing speed: The faster you print, the less dense your supports need to be to get quality coverage.

- Desired print quality: For higher quality overhangs, you can increase the density (at the expense of printing time). However, if it is too high, removing the support can sometimes damage the seal.

- Overhang size: The greater the angle of the overhang, the more dense supports you need. Especially for 90-degree overhangs, a support density of at least 15% is recommended.

- Removal on supports : The denser the supports, the harder it is to remove them (and the more material you waste).

Above and Beyond: Advanced support settings

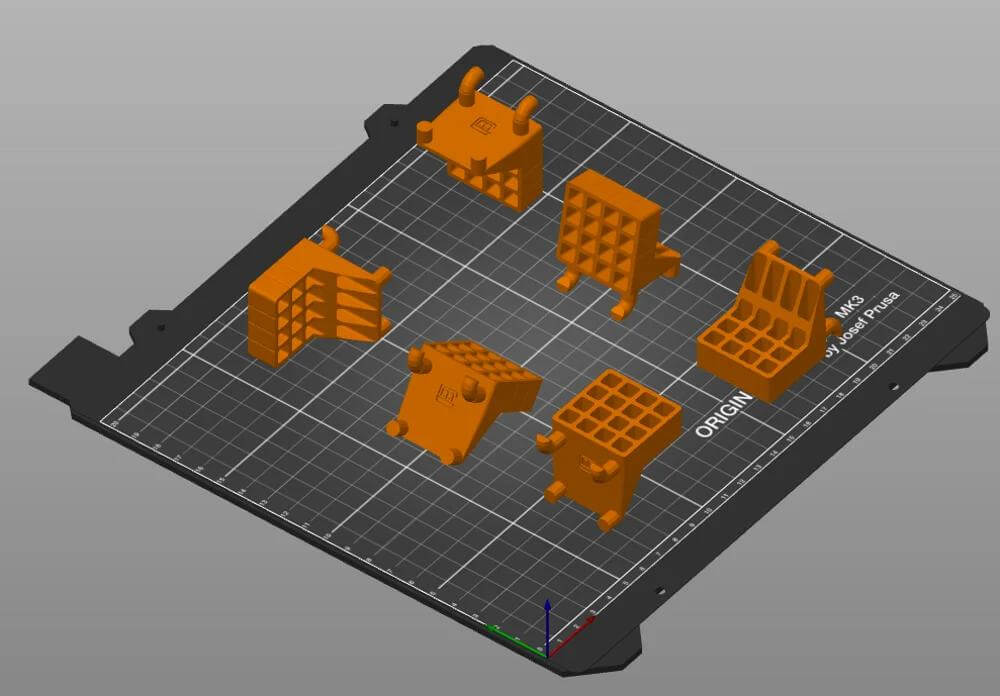

(Source: Prusa Printers )

Girl there are many other settings to fiddle with so you can perfect your print. You may never need to touch these settings, but it's always good to know they're there.

- Support Placements: You can choose where Cura will generate supports: everywhere (including on the model) or from the build plate (ie only those supports that would touch the bed).

- Support Overhang Angle : This controls the minimum overhang angle at which Cura will generate supports. (This is 45° by default.) If your printer can handle up to 70° quite well, changing this setting every now and then helps save threads and keep the removal job running.

- Support Z Distance: This is the gap between the top layer of the support and the first layer of the model. A little space is needed so that the supports can break off easily and not actually melt into the model. A good value to start with is the height of one layer. If you find that your supports are too glued to the model, consider increasing this value a bit.

- Gradual Support Infill Steps: Cura has a small option to help you save time and printing material. For those really tall and dense props, Cura will print them with lower density on the bottom and higher density near the model where you actually need it. This setting controls how many times the slicer will halve the support density from top to bottom.

0 Comments