Forward AM, the 3D printing division of chemical giant BASF, is doing more than just developing and marketing a variety of materials for the 3D building industry, such as threads, powders and resins. They are also a provider of additive manufacturing solutions. Take, for example, their latest message about partnering with a printer manufacturer BigRep for new material for printing concrete forms. "3MG Bonev“Ltd. is a regional representative of BigRep printers, as a partner company with B2N.

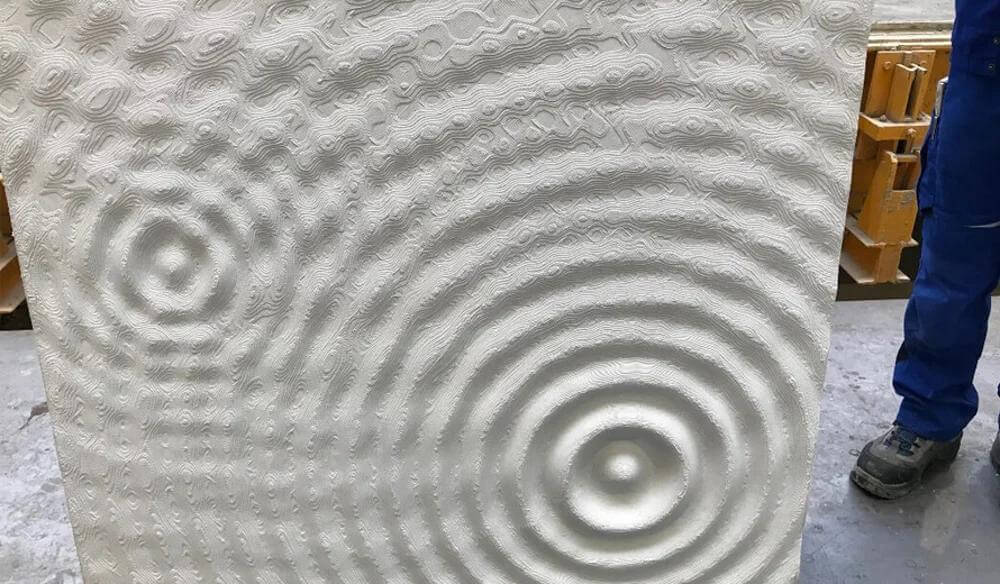

Instead of a material or product, Forward AM offers a service that shows a fast-growing application for large-format 3D printing: making concrete forms for architectural and artistic projects.

"New architectural and engineering techniques allow an entirely new approach to construction, with large-scale 3D printing pushing the boundaries of current construction techniques," said Forward AM.

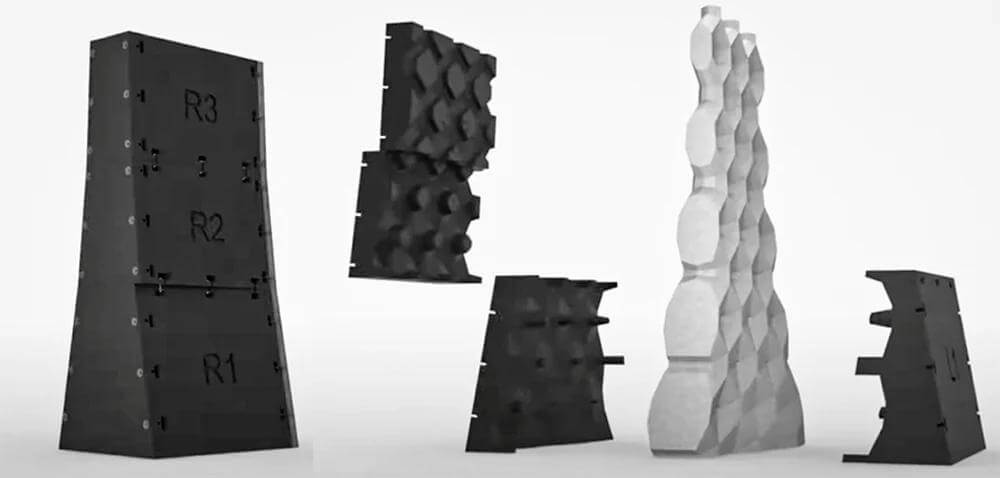

Their new service is a workflow from design to production that provides customers, such as construction companies and architects, with custom formwork that uses a new polymer designed by Forward AM, specifically designed to use BigRep wide format printers.

Water drop type facade forms, shown below, is an example of the service. It was initially modeled using design software, then redesigned as an optimized 3D printed mold, printed with Forward AM's patented material on a BigRep printer, and finally cast in concrete.

How does the process work? Customers present their design concepts to Forward AM engineers, who create the matrix digitally, then take care of printing the formwork and sending the part where the molds will be cast into concrete (such as a factory or directly on the construction site).

0 Comments