Waterproof 3D printing is easier to achieve than you think. Read about materials setting up slicer and tips for further processing!

Waterproof or waterproof?

Although printed 3D parts have many advantages, they are often not waterproof. Many people have misconceptions about what "waterproof" means, so let's get this straight. There are waterproof and waterproof, and they are very different.

Water resistance means that water will not affect the part, while water tightness means that water can neither enter nor leave the part. In practice, you may want the footprint to be waterproof if exposed to rain or humid climates. Whether this prevents water from entering is irrelevant.

For example, if you are printing 3D part of a car (say, part of a bumper), you don't need to make it waterproof, but it should be waterproof to make sure it doesn't break down or deform in the rain. However, if you are printing a water bottle, it must be watertight to retain the liquid.

In this article, we will focus on how to waterproof your 3D printed pieces. We will show you several different methods, including material selection, cutting settings, post-processing and testing.

Choice of material

Some materials are more vulnerable to chemical reactions and deformation than others, which can lead to non-waterproof parts. If a material reacts to water, the 3D imprint of that material is likely to deform when it comes in contact with water or is placed in a humid environment. So, the choice of materials should be your first attention.

Just remember that this is not the only step. Although some materials may be labeled as waterproof, parts made from them may not be.

Materials

If you print FDM, you will probably consider three main materials: PLA , ABS and PETG . Let's take a closer look.

- PLA is not known as the most waterproof material, but it should work. In particular, it should work well as long as it interacts with cold rather than hot water.

- ABS is an excellent material for waterproof printing. The parts can crack and deform when cold, but it is reported that its waterproof properties otherwise last a long time.

- PETG , a modification of PET used in water bottles, is a great material for making waterproof prints. PETG is generally considered to be waterproof and also has excellent thermal resistance. This material is probably your best bet for printing waterproof parts, as long as you perform other waterproofing techniques.

Food Safety

If you plan to use a 3D printed part for something that will come in contact with food or drink, you should use a food-safe material such as PP or PETG, not ABS or ASA. Before printing, make sure that the manufacturer of the particular thread states that it is safe for food.

Heat resistance

Heat resistance has nothing to do with the part that is waterproof, but depending on the intended application it may be important. For example, dishwasher parts are subjected to extreme temperatures and a lot of water, so the choice of material is especially important. Be sure to choose a heat-resistant material that is also waterproof (ABS or PETG for example).

Slicer settings

One of the most important factors for 3D prints is the way they are cut and with what settings. Among other things, the settings determine how tight, dense and protected the 3D printed part is, which in turn can affect how waterproof it will be.

Just keep in mind that while cutting settings play a big role in making 3D printing waterproof, some models are more difficult to waterproof than others. Complex models with many details are more difficult to waterproof, so be sure to make your model as simple as possible.

Extrusion

Intentionally extruding your fingerprints can make the parts more waterproof, as there is a reduced chance of gaps in your fingerprint. You can do this by increasing the extrusion multiplier, sometimes called "flow rate", from your slicer.

You will also want the many layers of your print to stick better to each other, and you can do this by increasing the temperature. Raising the temperature can also help with excessive extrusion.

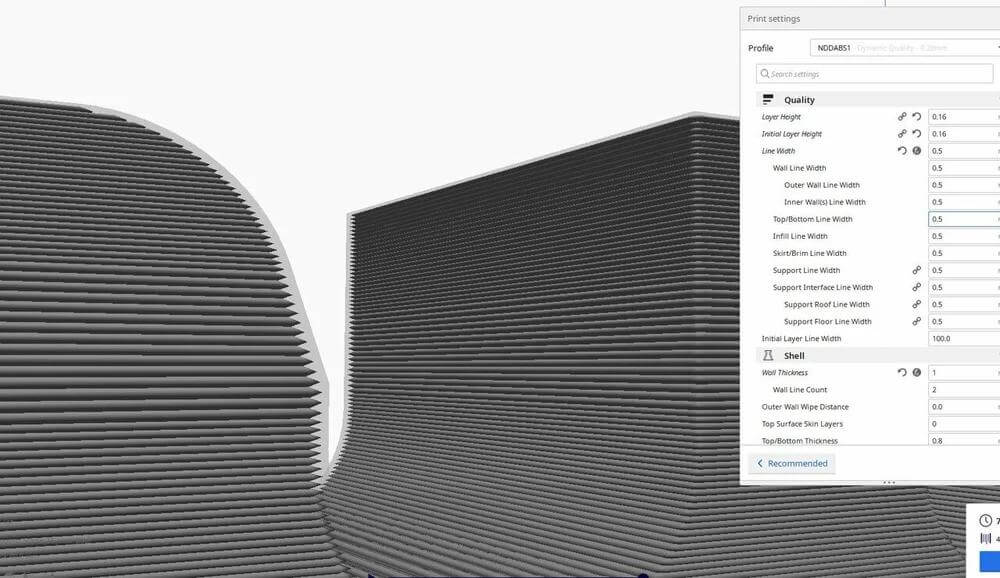

Shells and stuffing

You also need to increase the number of shells you use on the print. Adjusting this setting adds a larger border that covers the executed part of the 3D fingerprint.

Consider using a higher fill rate. This will add more filling to your print, which can help keep your shape and structure.

Nozzle size

While this is not a slicer adjustment per se, the wider nozzle can help make the parts more waterproof. The wider nozzle means thicker extruded lines, including shells in part.

Layer height

Using a higher layer height setting can improve the water resistance of the fingerprint because it creates higher layers. As a result, the imprint will have fewer of them, which means fewer weaknesses (ie, layer lines) where the piece can potentially leak water.

Subsequent processing

Post-processing is one of the best ways to make the 3D printed part waterproof. In particular, smoothing layers can give great waterproof results. It blends layers, eliminating gaps in the layer line and creating a tighter seal around the part.

The smoothing of the layers can be done in several different ways, but the main technique is to apply a solvent on the soluble seal. Some materials are soluble in certain chemicals. ABS dissolves, for example, in contact with acetone.

- Acetone: This is probably the most popular solvent used for post-treatment. The smoothing of the acetone layer works with ABS, ASA, HIPS, PMMA and polycarbonate fibers.

- Epoxy resin: Another method of post-treatment is to coat the impression with epoxy resin. Epoxy quickly smoothes layers of lines on 3D prints, making parts less vulnerable to water.

- Wax: Although less common, wax is a good candidate for waterproofing fingerprints. It does not dissolve the layers like acetone, but rather fills all the gaps between the layers.

Testing

Once you have created a waterproof part, it is good to test it. You should not just assume that by following the recommendations above, you will always have a waterproof part.

To test your fingerprint, leave it in slightly cold water for at least a few hours. Then remove the part and let it dry for about an hour. If you notice any deformations or cracks, then your part is not waterproof.

If your part does not turn out to be waterproof, we suggest you reconsider the above recommendations: adjust the settings of your slicer, perform a larger post-processing and possibly even use a different material.

You may also have a printing problem, so be sure to check that all the systems on your 3D printer are working properly.

We wish you luck!

"3MG Bonev" Ltd. can save you all these headaches by trusting us and using our knowledge, skills and techniques!

0 Comments