Хигроскопията е невидимият убиец на 3D разпечатките. Разберете какво представлява, ефектите му върху печатането и как можете да го избегнете!

Случвало ли ви се е да печатате със стара нишка или материал, който е бил изложен на влага? Ако сте имали, вероятно сте се сблъскали с проблеми с качеството на печат. Най-вероятно това се дължи на хигроскопията , която по отношение на 3D печата е появата на нишка, абсорбираща влага.

Повечето нишки са естествено хигроскопични – някои повече от други. Това означава, че когато има влага във въздуха (влажност), нишката естествено я абсорбира. Въпреки че е трудно да се забележи предварително, хигроскопията е фактор, който влияе негативно върху качеството на 3D печат.

Влагата в материала за печат не може да се види, но когато я загреете в горещия край на 3D принтер, можете. По същество водата кипи, докато нишката се топи, и това причинява бълбукане.

В тази статия ще разгледаме по-подробно как хигроскопията влияе върху качеството на печат, кои материали са хигроскопични, кои са по-малко и как можете да предотвратите развалянето на вашите отпечатъци от хигроскопия.

Ефекти върху качеството на печат

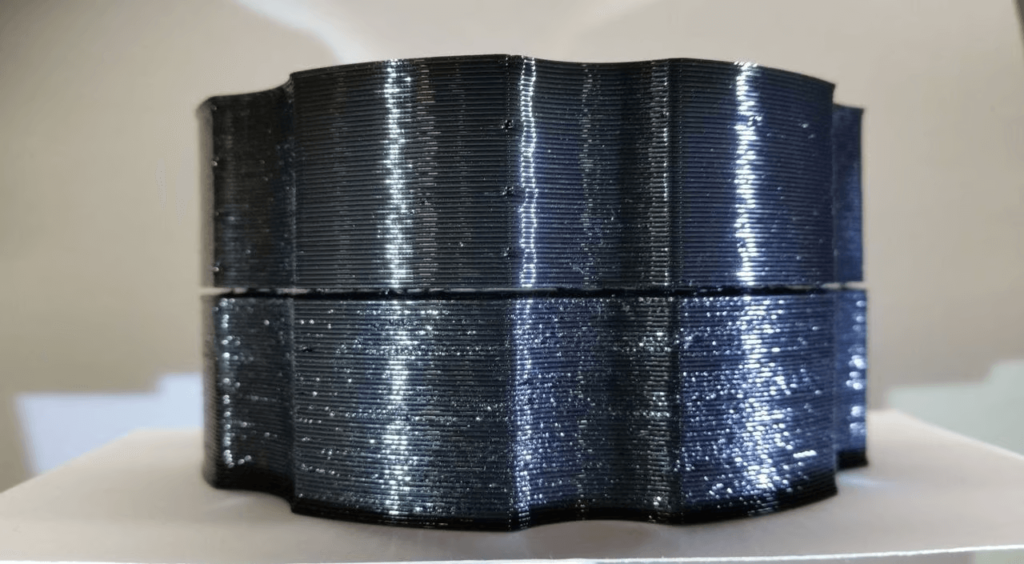

Можете ли да познаете кой печат е направен със суха нишка? (Снимка: bobstro чрез Prusa Research )

Когато хигроскопичният материал абсорбира влага, печатането с „мократа“ нишка може да доведе до изобилие от грешки при печат. Някои от най-честите признаци за влажна нишка включват следното:

- Мехурчета или петна в слоеве за печат;

- Нанизване;

- Засядане в екструдера;

- Чуплив филамент , меки и чупливи части;

- Лоша адхезия на леглото

- Проблеми с екструдирането

Ако погледнете снимката по-горе, можете да видите разликата между печат с мокра нишка (отдолу) и суха нишка (отгоре).

Това не означава, че влажната нишка може да бъде единствената причина за тези проблеми, но е сред най-вероятните и трябва да бъде един от първите аспекти, които да проверявате, преди да разгледате самата машина.

След като вече знаем какво може да се случи, нека разгледаме по-отблизо кои нишки са по-хигроскопични от други.

Най-засегнати материали

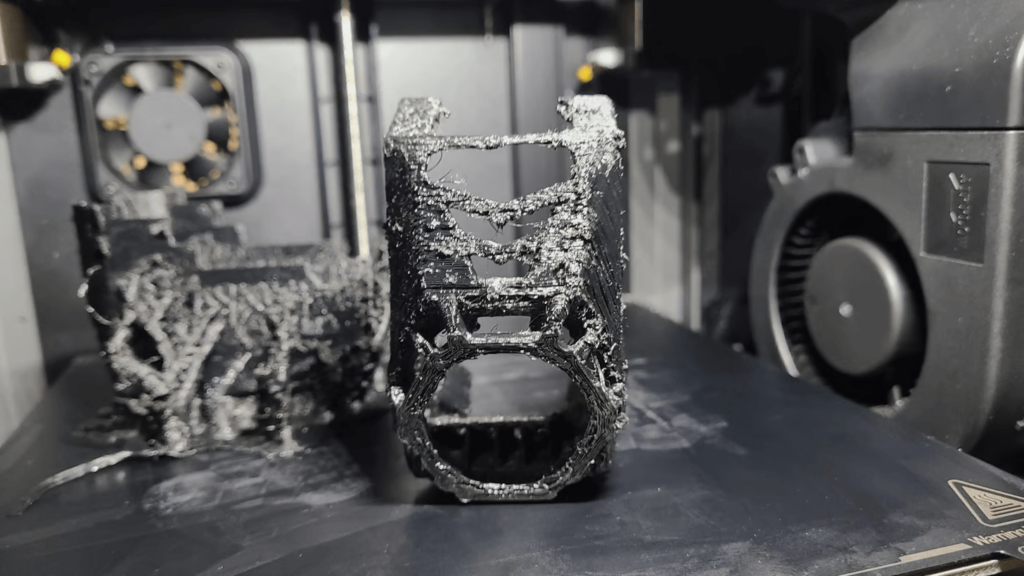

Полиамидът ( PA / Nylon) е много хигроскопична нишка (Източник: ontopathogenic_ чрез Reddit )

Както споменахме по-горе, много от материалите, използвани за нишки за 3D печат, са донякъде хигроскопични. Това пoказва, колко бързо различните материали абсорбират влагата – това варира. Следните материали са най-склонни да се овлажняват бързо:

- Nylon, както и други полиамиди (PA)

- PVA (често използван като поддържащ материал)

- TPU

- PLA

- ABS

- Поликарбонат (PC)

- PETG

- Many flexibles

За всеки, който се интересува от по-дълбоко гмуркане, BCN3D проведе изследване за ефектите на влажността върху филаментите за 3D печат и пусна бяла книга, описваща своите открития. Те разгледаха основно трите най-хигроскопични нишки в тяхното портфолио, а именно PA, PVA и TPU. От трите PVA абсорбира най-много влага по време на техните експерименти, а TPU най-малко. Като се има предвид това, TPU се справя най-зле, когато става въпрос за неговата устойчивост на лоши условия на съхранение.

Кои са по-малко хигроскопични?

В сравнение с изброените по-горе материали, следните са по-малко податливи на хигроскопични проблеми:

- ASA

- Polypropylene (PP)

- HIPS (най-често използван за поддържащ материал ABS)

Това не означава, че те няма да абсорбират влагата – ще го направят, но не със същата интензивност или толкова бързо, колкото споменатите по-горе материали.

Превенцията винаги е оправдана, без значение какъв филамент имате. И така, нека да разгледаме какво може да се направи, за да се ограничи излагането на вашите нишки на влага.

Съхранение на нажежаема жичка

Използването на суха кутия (или отделни такива) може да запази нишките… сухи (Източник: Austin чрез Printables )

Познавайки често срещаните симптоми и главните виновници, нека поговорим за това как всъщност да се справим с хигроскопията. Естествено, първата стъпка е превенцията, т.е. правилното съхранение .

Най-общо казано, ключът е нишката да се съхранява в сух, водонепропусклив контейнер. Трябва да правите това възможно най-често между разпечатките.

Солидна опция за съхранение е суха кутия , която физически ще отдели вашата нишка от околната среда. Този метод работи както за дългосрочно, така и за краткосрочно съхранение, стига да има някакво водонепроницаемо уплътнение на отвора. Имайте предвид, че има разлика между суха кутия (която поддържа околната среда… суха) и сушилна кутия , която активно нагрява нишката, за да премахне влагата.

Ако искате да съхранявате нишка до няколко дни, плътно затворена торбичка ще свърши добра работа. В този случай обмислете използването на десиканти за отстраняване на кислорода и влагата.

В зависимост от опцията за съхранение, която избирате, независимо дали може да се купи или направи сам, можете да разгледате дизайн, който включва отвор (като същевременно държи кутията херметична). Това ще ви позволи да използвате нишката, докато се съхранява.

Сушене на нишка

PVB е хигроскопичен, така че го изсушете преди печат (Източник: random-builder чрез Thingiverse )

Печатането с нишка, която се съхранява в суха кутия, е чудесна идея за предотвратяване на проблеми, свързани с хигроскопията. Но ако не сте били бдителни за правилното съхранение на материала, тя вероятно е абсорбирала малко влага от въздуха, особено ако сте я имали доста време.

Добрата новина е, че не е необходимо да купувате друга макара. По-скоро ще трябва да разберете дали вашата нишка е влажна и ако е така, да я изсушите.

Откриване на влажна нишка

За да определите дали нишката ви е „мокра“, трябва да обърнете внимание на това как печата. Влажната нишка често води до по-ниско от очакваното качество на печат .

Ако макара с нишка е абсорбирала прилично количество влага, можете да направите прост тест. Всичко, което трябва да направите, е да прокарате малко нишка през дюзата и да слушате внимателно. Ще разберете, че имате мокра нишка, ако чуете пращене/ пукане, докато нишката се екструдира. Друга индикация е, ако видите пара да излиза от печат (топло среща студено) или някой от споменатите по-горе проблеми с печата.

Сушене на нишка

Направихте тестовете и нишката ви е влажна. Време е да я изсушите.

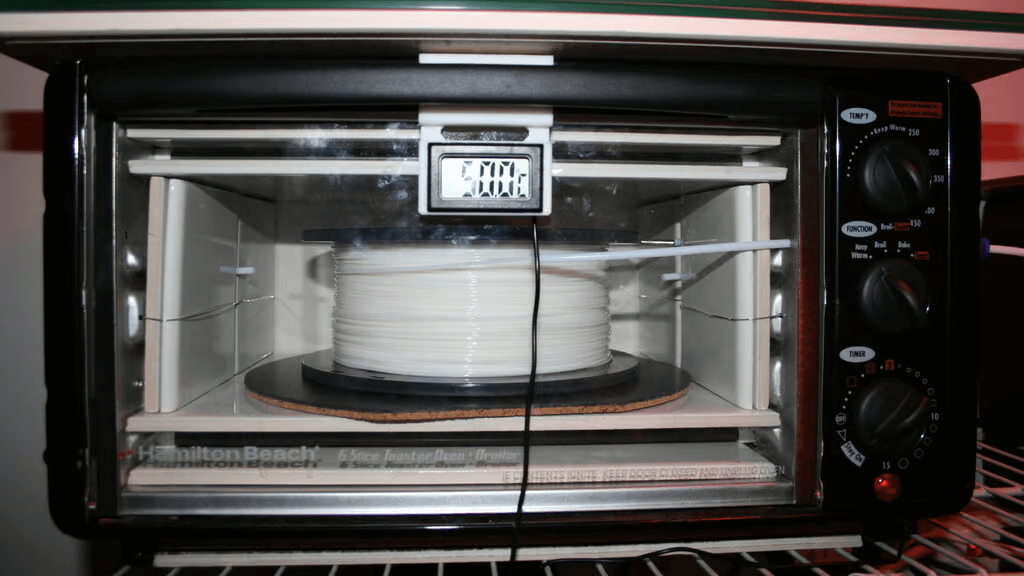

Всъщност изсушаването на нишката е лесно. Просто поставете макарата във фурната и за PLA задайте температурата на около 40-50 °C. След това го оставете там за около 4-6 часа. Други материали, като ABS и Nylon, ще се възползват от по-високи температури (~80 °C). Можете да проверите предложените температури от Bambu Lab за повечеto материали, но винаги се препоръчва да се информирате от съветите на производителя.

Също така избягвайте прекомерното изсушаване на вашата нишка, тъй като това може да доведе до чупливост.

Ако фурната не е опция, можете да изберете кутия за сушене. Dry Box 2.0 на Creality и FilaDryer S1 Plus на Sunlu са страхотни опции, но можете също да използвате подход „Направи си сам“ .

Ако имате нужда от допълнителни разяснения, как да се спасите от влагата по Вашите материали, кой материал да използвате за Вашите проекти или други казуси в адитивните технологии- не се колебайте да се свържете с нас:

0 Comments