Изследователи от Zurich’s Departments of Complex Materials and Renewable Energy Sources успяха да произведат сърцевина на слънчев реактор от индивидуално 3D отпечатана керамика. Слънчевите реактори се използват за производство на въглеродно неутрални течни горива като слънчев керосин за космическата индустрия. Следователно технологията има голям потенциал за авиация с по-ниски емисии, което е възможно чрез използването на адитивно производство. По-щадящи околната среда горива от този вид вече могат да се произвеждат в по-големи количества благодарение на повишената ефективност на слънчевите реактори. Проектът в ETH Zurich става възможен с финансиране от Швейцарската федерална служба по енергетика.

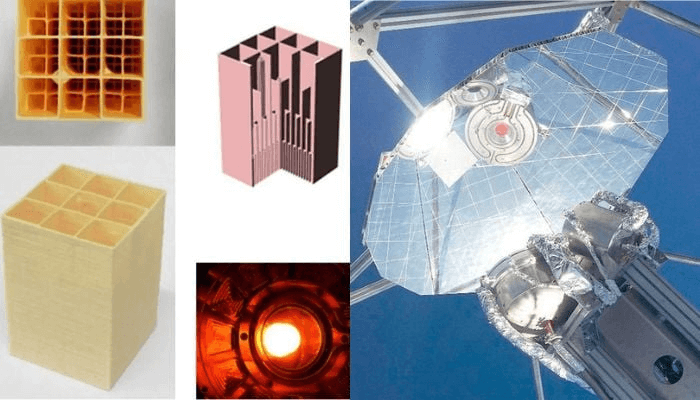

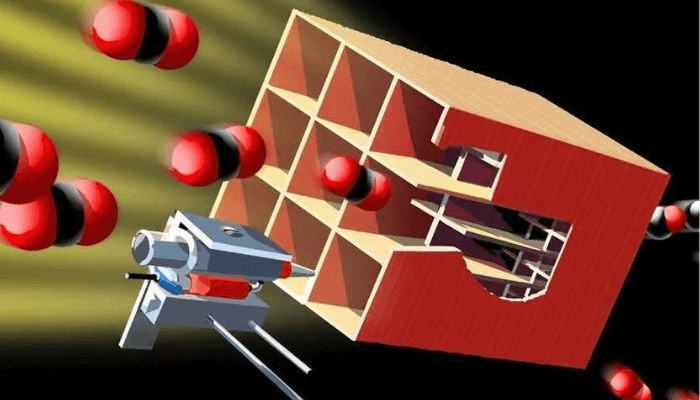

С две думи, слънчевият реактор функционира като първо се осветява от слънчева светлина от параболично огледало. Новата структура на реактора включва 3D отпечатан комплекс от йерархично подредени керамични структури. Той се отваря на повърхността, обърната към слънцето, и се стеснява допълнително към задната част на реактора, улавяйки топлината. Както показаха първите успешни тестове в ETH Zurich, цялата структура е в състояние да достигне реакционна температура от 1500°C поради концентрираната слънчева радиация. В допълнение, слънчевата радиация се транспортира по-ефективно във вътрешността на реактора благодарение на 3D отпечатаните компоненти. В резултат на това се произвежда два пъти повече въглеродно неутрално слънчево гориво със същото количество слънчева радиация в сравнение с предишните изотропни структури. Самите керамични конструкции се отпечатват чрез екструзия от специално разработена паста от 3D принтера. Екструдираната паста се състои от голямо количество частици cerium oxide, за да се получи възможно най-реактивният материал и по този начин да се увеличи максимално ефективността на слънчевия реактор.

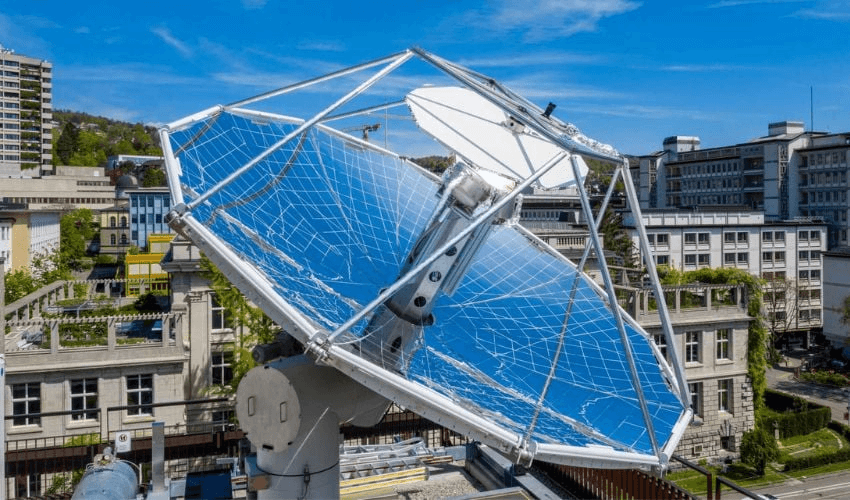

ETH Zurich изследва слънчевите горива повече от десетилетие и преди това демонстрира процеса на тяхното производство в университетския кампус през 2019 г. Инженерите от швейцарския университет също вече са разработили слънчев реактор, в който се използва енергията от концентрирана слънчева радиация за производство на синтезен газ (водород и въглероден окис) чрез поредица от термохимични цикли за разделяне на вода и CO2. Това от своя страна се използва за производството на течни слънчеви горива като слънчев керосин като гориво за самолети. Тези горива са CO2 неутрални, тъй като по време на изгарянето им се освобождава само толкова въглерод, колкото е бил извлечен преди това от въздуха за производството на синтезния газ. Структурите, използвани преди това в реактора, имаха изотропна порьозност. Слънчевите лъчи, удрящи реактора, бяха отслабени по пътя си в реактора поради свойствата на повърхността. Това означава, че оптималната вътрешна температура не може да бъде достигната в реактора, което ограничава неговата производителност и производство на гориво.

Според ETH Zurich тяхната новоразработена технология вече е много напреднала, поради което отделните компании на ETH, Climeworks и Synhelion, се стремят да доразвият технологията комерсиално, да я пуснат на пазара и да си сътрудничат с компании като летище Цюрих и Lufthansa. Освен това технологията за 3D принтиране на керамичните конструкции вече е патентована. Synhelion също вече получи лиценз от ETH Zurich. Steinfeld, професор в катедрата по механично и технологично инженерство в ETH Zurich, подчертава: „ Тази технология има потенциала да повиши енергийната ефективност на слънчевия реактор и по този начин значително да подобри икономическата жизнеспособност на устойчивите авиационни горива “.

0 Comments