Gaps in 3D prints are annoying defects that mess up the way parts look and work. Check out this guide to easy fixes and how to avoid them!

3D printing is a skill that takes effort and a significant amount of practice to master. Still, there's nothing more frustrating than having your 3D prints consistently fail. After all, we just want to produce great quality prints that look good and function as they should.

Fortunately, the mighty 3D printing community is always ready to help. We have many guides and tutorials to help both beginners and advanced users. So, don't give up on your 3D prints just yet!

If you're experiencing gaps or holes in your 3D prints, it can be a difficult problem to fix, especially since several different factors can cause them. In this article, we will look at the possible defects that appear as gaps, their potential causes, and how you can deal with them.

Gaps in the first layer

The first layer is considered the most important of all, as it provides the foundation for the entire model. Therefore, it can be the deciding factor between a successful or unsuccessful print. There are several anomalies that can lead to a gap in the first layer, and all of them can cause more problems than just aesthetic defects.

Let's first look at how different types of gaps occur and their potential causes. Next, we'll go over the steps to deal with them.

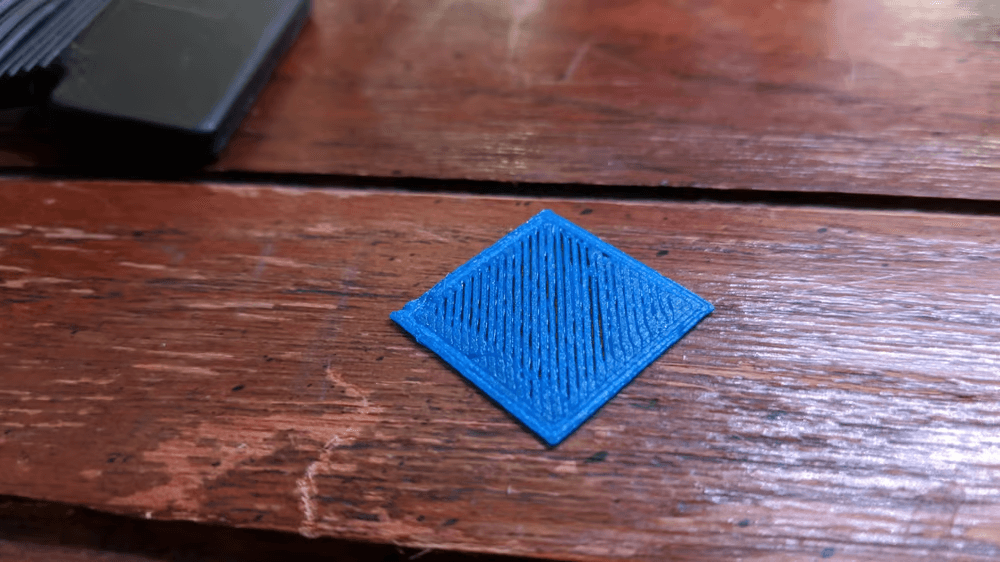

Gaps between lines

reyemxela via Reddit )

THE PROBLEM

Your print has repeating gaps between the extrusion lines in the first layer. The lines appear to be evenly spaced apart, creating a grid-like pattern rather than a solid flat surface at the bottom of the print.

POTENTIAL CAUSES

One potential factor is that your Z offset is too large. The Z offset adjusts the physical distance between the nozzle and the build plate. In this case, the nozzle appears to be too far from the bed, preventing a slight crushing of the layer lines during extrusion, which - with an adequate Z offset - would fill the surface. Not extruding enough can also be the cause, as each line won't be as thick as expected, leading to the nasty gaps between the lines.

Areas of missing material

THE PROBLEM

There are areas of the first layer of the print with no material, although this area is outlined by the nozzle. This is most noticeable while printing the first layer. Depending on the severity, it can potentially harm the entire print as the adhesion of parts will be compromised.

POTENTIAL CAUSES

Essentially, the gap between the nozzle and the bed is too narrow, preventing the material from extruding. In extreme cases, the nozzle will literally scrape the build surface, potentially causing clogging or even hardware damage.

The most likely causes are a poorly leveled bed or inadequate Z offset calibration. Small irregularities or distortions in the building plate or residual waste can also cause minor gaps in the first layer.

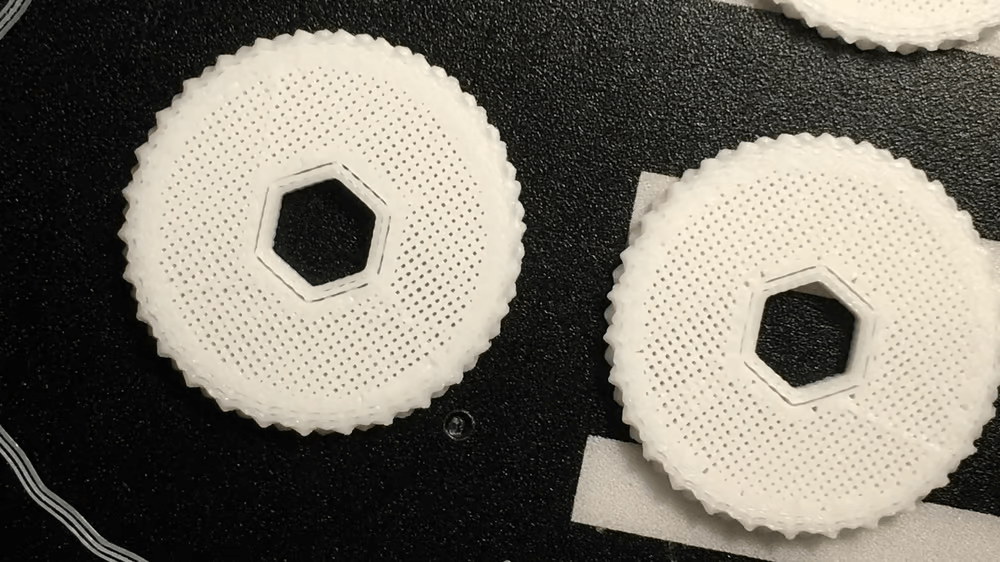

Hole-like anomalies

geofox784 via GitHub )

THE PROBLEM

Your print has small speckled gaps in the first layer that look like holes or short line segments. They can appear on entire surfaces or individual islands. Such defects are easily noticeable and affect the aesthetics of the model.

POTENTIAL CAUSES

Poor bed adhesion can prevent extrusion lines from attaching to the build plate, especially at the beginning or very end of segment extrusion. Extrusion-related problems (such as under- or over-extrusion) can also lead to the formation of these gaps in the first layer.

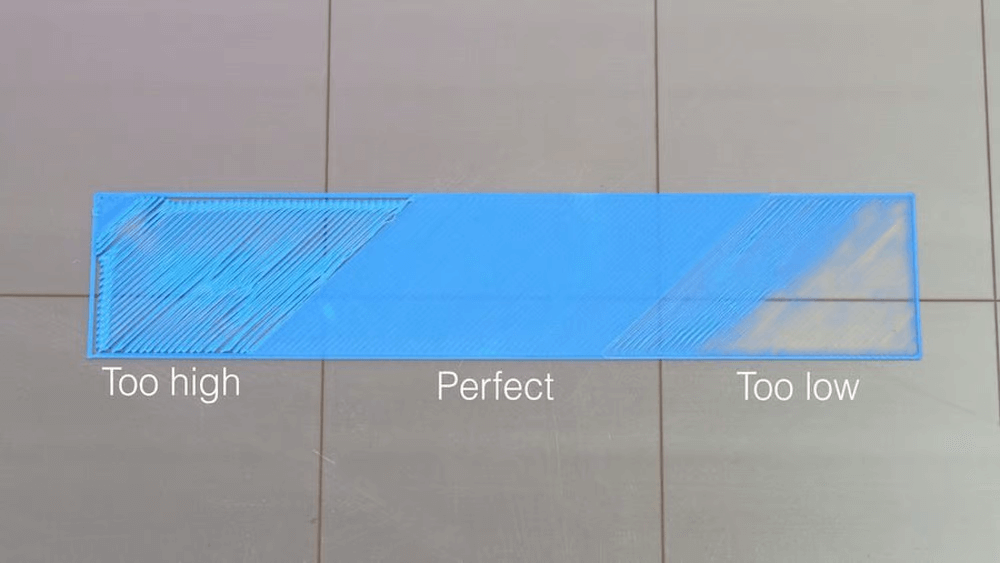

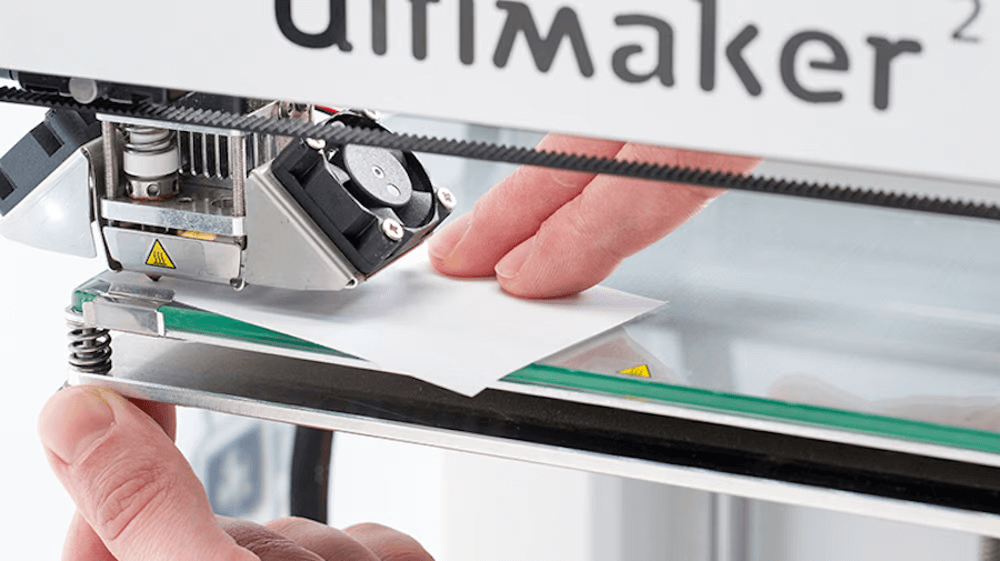

Solutions: Gaps in the first layer

(Source: wannamaker via UltiMaker)

Most of the problems mentioned above can be solved by properly calibrating the printer. For gaps between lines and areas of missing material, the Z offset adjustments should do the trick, ensuring the integrity of the first layer and avoiding adhesion issues that could lead to pinhole-like anomalies. Precise calibration of the extrusion will ensure that the correct amount of material is deposited, resulting in a well-built first layer.

Make sure you always keep your bed clean and level. Also, use proper bed bonding techniques for materials with high thermal expansion, such as ABS and nylon.

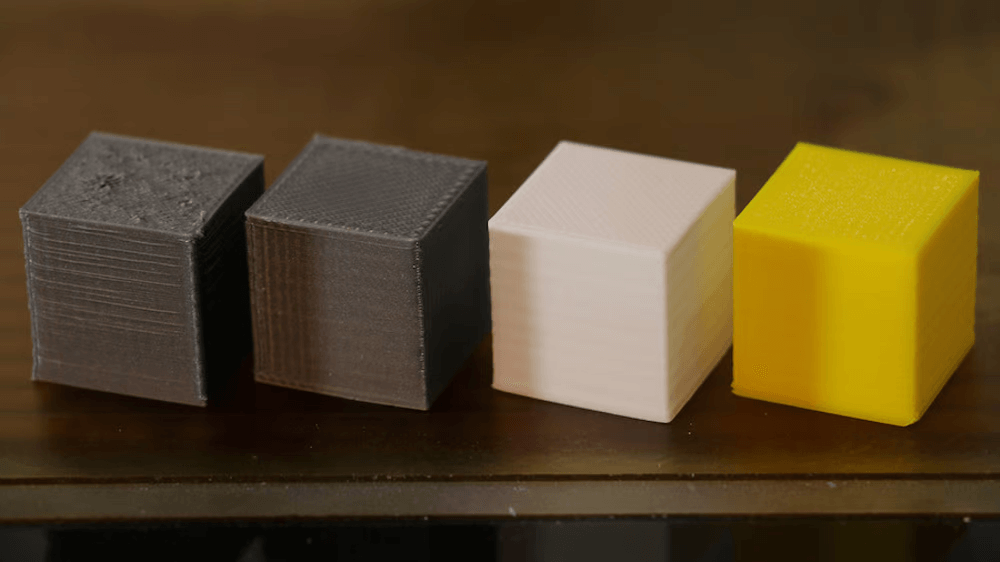

Gaps between the soybeans

As we all know, 3D printing works by adding thin layers of material, one on top of the other, until a three-dimensional object is created. Each layer must be adequately deposited on top of the previous one to create strong and good looking parts.

Most ply gaps are caused by perimeter extrusion problems or poor ply adhesion, as we'll see next. However, there are a few other flaws that could be considered omissions, and for that reason we'll look at them as well.

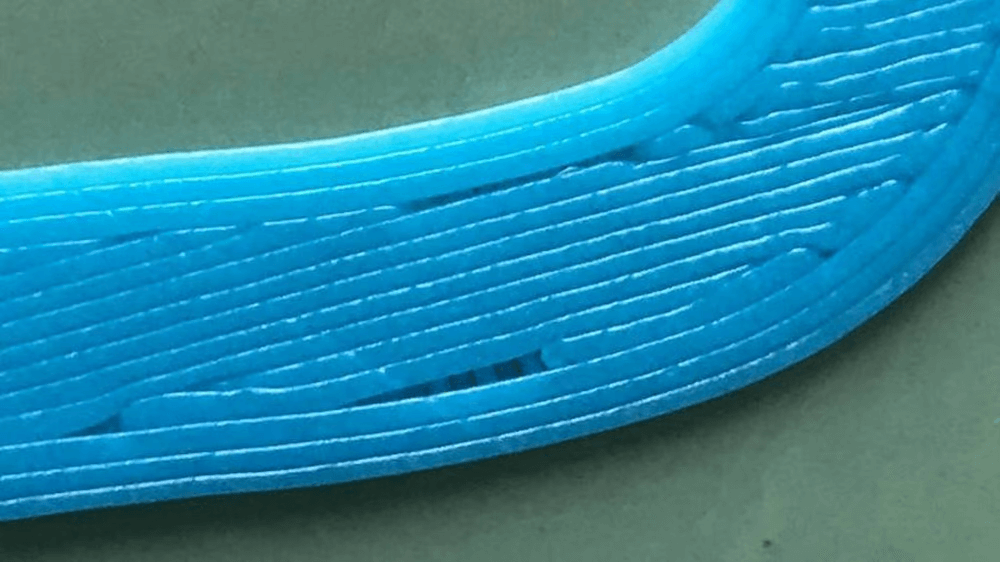

Holes and stains

THE PROBLEM

Defects appear on the side surfaces of the 3D printed models. These are not gaps so much as small holes and spots from failed printing that lead to poor surface coverage. They can be either isolated spots or continuous spots on the surfaces of the part.

POTENTIAL CAUSES

These are mainly the result of extrusion problems where the material is not deposited properly. Improper retraction settings can also be a cause, as they can prevent extrusion from starting after a move. Moisture in the thread can also cause small spots on the surface.

Separating the layers

THE PROBLEM

Two or more layers are partially separated. This phenomenon is also known as delamination and is quite common in 3D printing methods other than FDM. In extreme cases, layer separation causes the entire printing process to fail.

POTENTIAL CAUSES

Low bond strength between layers is usually associated with low die temperatures, insufficient extrusion, high speed printing, or sometimes layer heights that are too high. Materials with high thermal expansion are more susceptible to this as the phenomenon is similar to warping.

Solutions: Gaps between layers

For holes and marks, fine-tuning the 3D printer's extrusion calibration and retraction settings should prevent most, if not all, surface problems. Keeping filaments properly stored and dry should also improve print quality.

Now, layering happens for many reasons. To resolve the issue, try adjusting the nozzle temperature and cooling settings to optimal values. Lowering the print speed should also help bond the layers, along with the correct extrusion settings.

For materials like ABS and nylon, the printer housing is a great addition as it can help eliminate warping and aggressive shrinkage.

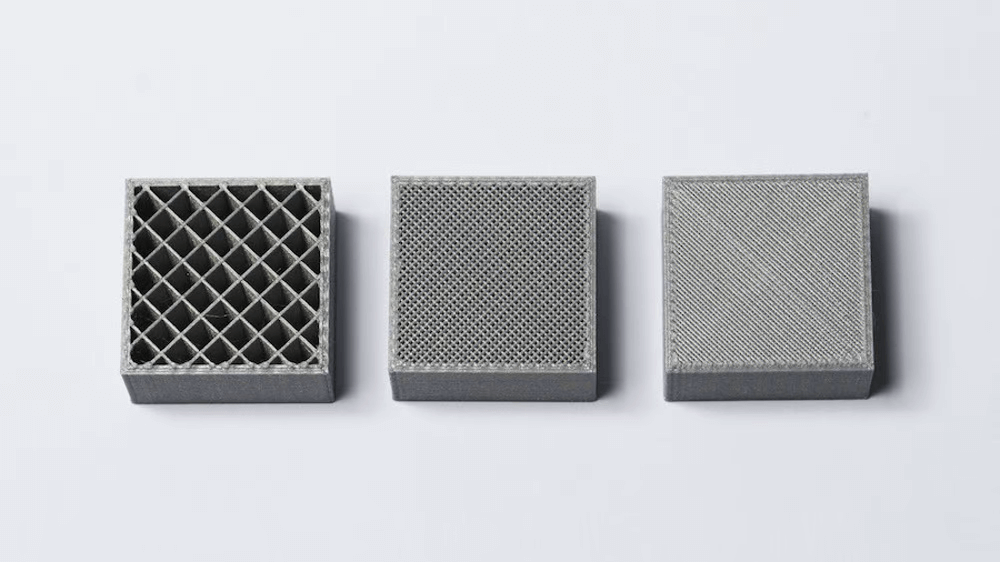

Gaps in the top layer

The top layers are the last to be printed, enclosing the model and its partially hollow interior. For this reason, they are printed completely solid – or at least they should be. Gaps on top layer surfaces are a fairly common problem that has multiple causes, as we'll see in this section.

Gaps between lines

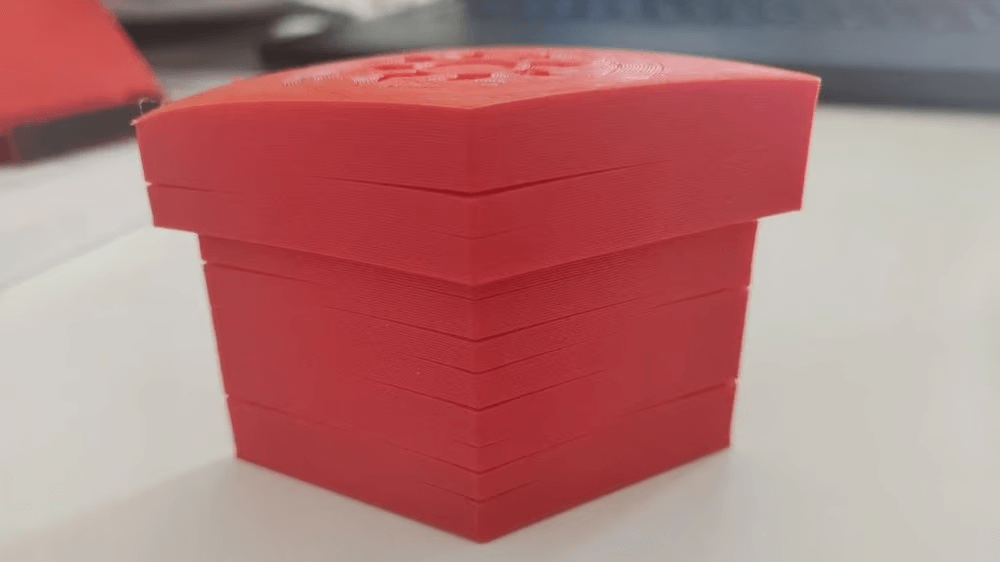

SirThunderCloud via Reddit )

THE PROBLEM

There are constant gaps between the layer lines, resulting in brittle surface top layers that are not truly rigid. This problem usually affects the entire layer, especially the areas printed on the volume fill of the part.

POTENTIAL CAUSES

Either not enough material is deposited or the base for that layer is not strong enough. It is also possible that both problems are present. Therefore, insufficient number of dense top layers, insufficient extrusion and too sparse filling can potentially lead to this situation.

Holes in the walls

THE PROBLEM

The stamp has holes between the top layer and its perimeter. This is also known as wall separation, and given that the fill is laid in straight lines, it is easily noticed in circular features such as holes and cylinders.

POTENTIAL CAUSES

Printing the top layer too quickly can cause this problem, as well as severely underextruding. In some cases, previous layers printed at too low a fill rate can also cause cracks in the walls.

Solutions: Gaps in the top layer

Besides properly calibrating the extrusion, increasing the number of solid top layers or fill percentage can eliminate gaps between lines in the top layers. To improve the base of the upper layers, it is also worth trying out different fill patterns.

Gaps in walls can be extremely difficult to fix. Some 3D slicers such as UltiMaker Cura and Simplify3D have specific print settings to correct this problem. A good place to start would be the Fill Overlap (Cura) or Contour Overlap (Simplify3D) settings, both of which control how much the fill overlaps the contour perimeters.

In addition, reducing print speeds and increasing volume fill percentages can potentially help the top layer lines to be stitched correctly.

0 Comments