Summary

- Maciej Szczepański, a veterinary medicine student from Poland, uses 3D printers to help injured dogs.

- He 3D prints prostheses that allow animals to fully enjoy their freedom of movement again.

- Before 3D printing, the geometry of the dog's "stump" is transferred to the modeling program using a 3D scanner.

3D printing technologies are constantly entering new, niche areas where there is a need for made-to-order objects. We learn about these remarkable apps on a regular basis. Today we have a story about Maciej Szczepański, a student from Wrocław, Poland, who successfully implemented modern technology in the animal world with an amazing mission. Using additive technologies, he designs and builds 3D printed prostheses for injured dogs.

From idea to reality: 3D printing functional prosthetics for animals

Maciej is a final year veterinary student at Wroclaw University of Environmental and Life Sciences, where he had the chance to research the field of animal orthopedics. In addition to participating in orthopedic operations, he likes to read specialized literature, from which he learns about the methods of providing assistance to injured animals. One of these methods is fitting a prosthesis to the animal. However, he notes that the use of animal prostheses in Poland is not as encouraged as, for example, in the United States. At this point, his idea of helping animals is alive.

"I wanted to create prostheses that would improve the quality of life of an animal that would use them." - says Machei, who started his project by helping two dogs - Sonya and Leto - victims of traffic accidents. After initially outsourcing part of the project, Maciej chose to 3D print the prosthetics himself to gain more autonomy as he decided to commit to this project full-time.

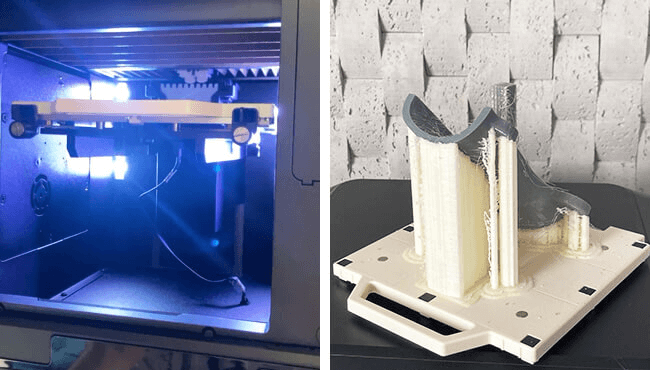

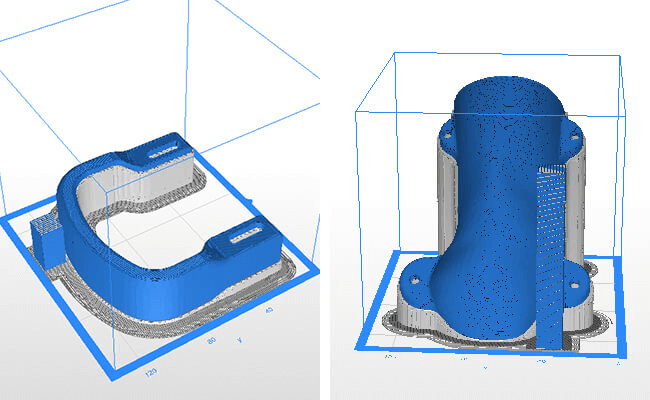

Maciej begins work on the artificial limb by getting to know the dog he will help. He used alginate to make an impression of the dog's stump. The impression is then filled with a special ceramic plaster. The future vet then 3D scans the resulting residual limb cast so that the 3D designer can prepare a digital 3D model. “All I have to do later is 3D print the prototype on my 3D printer, which makes my job much easier as I can print on site and check that my assumptions are correct. I no longer have to outsource this work.” Maciej points out. What's more, having a 3D printer allows the student to test different fill levels and assess the durability of the printed part.

Produce custom 3D models tailored to special veterinary needs

Each prosthesis is almost entirely 3D printed. The printed components include a socket that holds the dog's stump and an element that makes contact with the ground. As Maciej explains: “For the nest, I choose the option for dense filling until the "foot" has a little over the normal one filling density. " He also uses the option Hybrid Support , which allows it to save on support material while printing in dual extrusion mode.

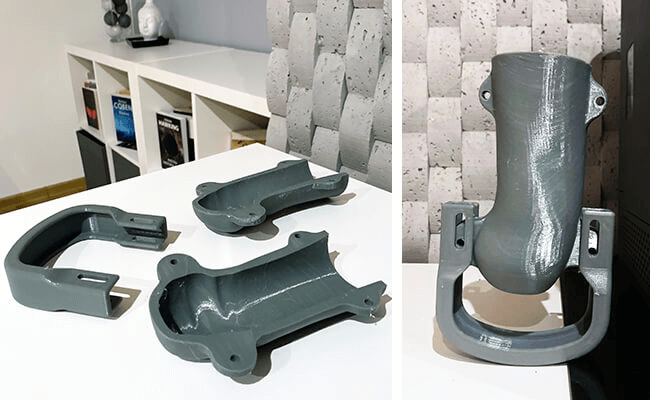

Assembled 3D printed prosthesis (right).

The filaments that Maciej used in his project are Z-PETG, Z-ULTRAT and Z-SUPPORT Premium. "I believe Z-PETG is particularly useful for prosthetics because of its high resistance to wear and tear." - says Maciej.

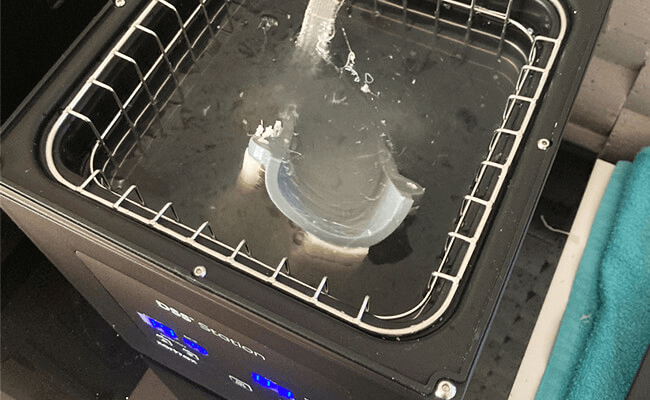

After 3D printing, Maciej dissolves the support structures, and this is actually the only post-processing step he applies in this project. Finally, Maciej used screws to assemble the three components of the prosthesis together, and placed a layer of fabric inside the 3D-printed socket to increase the dog's comfort. At this point, the object is ready to be carried by the dog. The student has no doubts about the role of 3D printing in his project and as he says: "Thanks to 3D printing, I was able to create custom prosthetics that fit the pet's special needs."

And Maciej's work is having the desired effects, helping dogs to fully enjoy their freedom of movement again. An interesting fact is that Leto – one of the dogs in Maciej's care – got used to his prosthesis, accepted it and started moving around in it almost like a healthy dog within 15 minutes of being fitted.

The advantages of a desktop 3D printer in a veterinary office

Despite having little technical experience in the field of 3D printing, Maciej finds working with his FFF 3D printer an easy and convenient task. "This was my first contact with a 3D printer and I managed without any problems." A great credit to Maciej is also the short time in which he can receive the finished prosthesis and hand it over to the animal in need, which takes no more than 3 days.

On top of that, Maciej sees 3D printing as a tool that allows him to create highly personalized items with minimized costs incurred during the process. Not only has he filled a niche by supplying artificial limbs to injured dogs, but he also plans to expand his business: “In the future, I would like to use the 3D printer to create other prostheses or to repair the ones I have already produced. " In fact, Maciej is in the process of creating a start-up company that will provide long-term support to animals with orthopedic problems.

0 Comments