When it comes to 3D printing software, the types and options can be numerous. Read on to find out what you must have!

3D printing can be an incredibly powerful tool to help you bring your projects to life. But to turn your ideas from digital to physical, your printer will need the right software file format to make it happen.

Here we have listed all the different types of software that will come in handy when you design and print parts. Of all the types of software we're going to discuss, only one is absolutely necessary. However, we'll also look at additional software tools that will enhance your printing experience.

The bare minimum

Technically speaking, the only thing you really need to print your 3D model is G-code, the programming language that plots specific coordinates on the print bed where your model will be produced. Although the G-code format is used in both "fused deposition modeling" (FDM) and resin 3D printers, the same G-code file is unlikely to work on two different printers. No two printers are the same, and their specific G-code files will most likely contain different commands based on the control board used or the dimensions of the print bed. For these reasons, it is safest to create your own G-code files for each model you want to print.

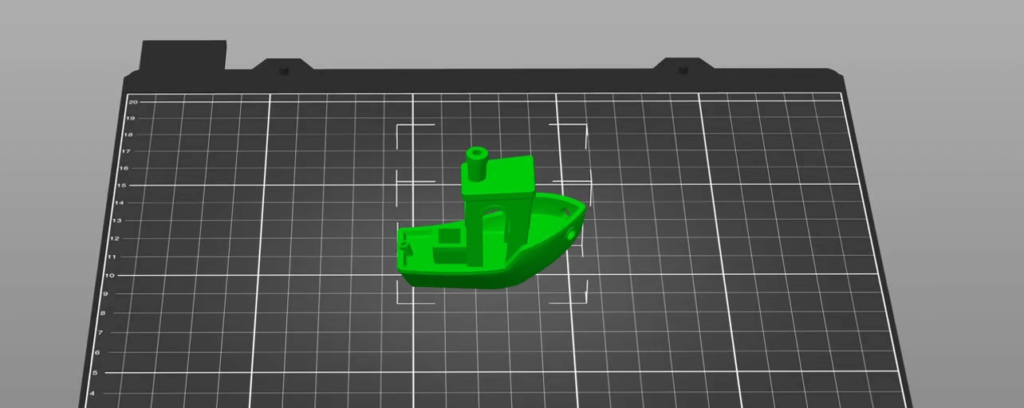

This means that the only type of software you really need to run your 3D printer is a "slices", which is the software that takes a 3D model and "slices" it into G-code. This is the bare minimum because you can always grab free STL files from file repositories like Thingiverse, Printables, MyMiniFactory, and more, so you don't need to design your own printable parts.

FDM Slicers

While G-code contains the mapping commands to print 3D models, a slicer is slicing software that can take a 3D model and make it understandable to your printer. Ultimately, it acts as an STL to G-code converter and then visualizes the print path from start to finish.

There is a huge selection of 3D slicers out there, some offered by 3D printer manufacturers, some supported by the open source community, and some a little bit of both! Here are some good FDM slicers to get you started, but if you're working with a polymer printer, you need a different slicer.

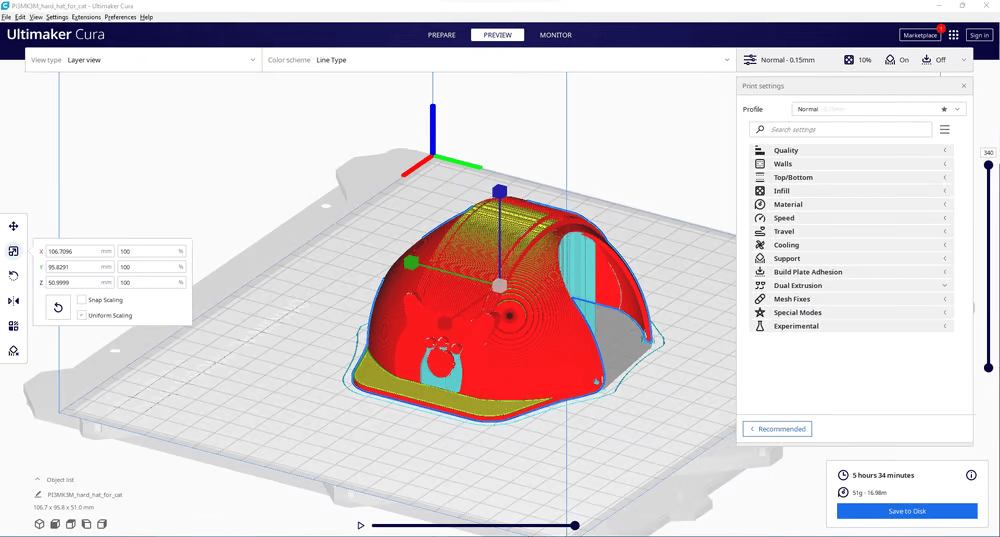

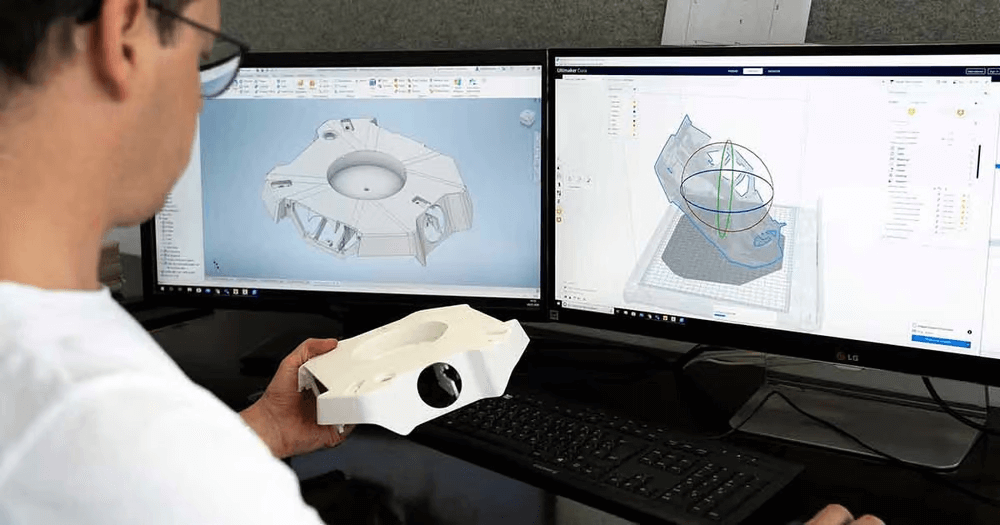

ULTIMAKER CURA

Ultimaker Cura is one of the most widely used open source slicing programs. But don't let the simple interface and free download fool you—under the hood, there are hundreds of settings that can be individually changed, earning Cura the 2019 Software Tool of the Year award at the 3D Printing Industry Awards. Cura is the perfect tool for both beginners and experts as it has presets for easy, medium and advanced difficulty levels. We have many articles about Cura to help you get started.

PRUSASLICER

PrusaSlicer is another incredibly popular slicing software that both uses and builds on its predecessor, Slic3r. Its support for multi-material prints, wireless connectivity, and presets for third-party printers easily make it a versatile option as your favorite slicer. Maintained by several Prusa Research developers, PrusaSlicer continues to improve with multiple new updates every year. In the spirit of the open source initiative, you can even contribute to its development by reporting bugs or suggesting changes on GitHub!

NOT MANDATORY BUT GOOD TO HAVE

Computer Aided Design (CAD)

There's nothing wrong with 3D printing ready-made files, but at some point you may start looking for ways to adapt or create your own models. To do this, you'll need 3D modeling software to turn your ideas into 3D printable files. Known as computer aided design (CAD), there are so many CAD options to choose from. To make things easier, we'll list our picks based on the two main categories of 3D modeling: parametric and direct modeling.

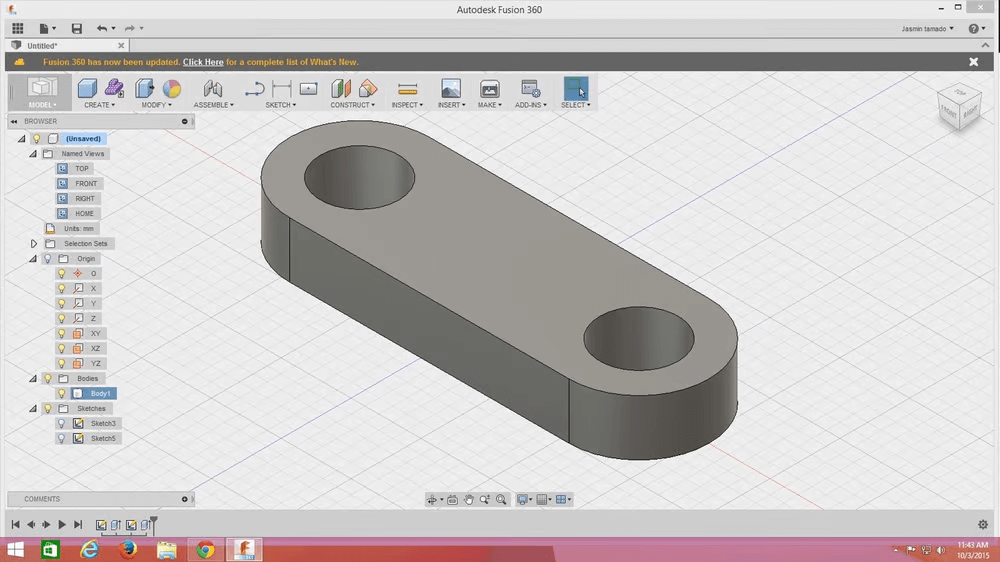

Parametric modeling

The parametric modeling approach to CAD is based on the geometry of the model and its dimensions. These simple shapes are continuously modified or edited in a series of steps, creating a "history" or dependencies that will affect the output of the model. Like time travel, if you go back and change a past dimension, all future functions that depend on that dimension will also change.

TINKERCAD

Tinkercad , from Autodesk, is a great browser-based 3D modeling tool for beginners. It's not a very powerful tool, but it's very easy to get into, combining basic geometric shapes to create more complex patterns.

FREECAD

FreeCAD is an open source CAD tool developed by the community that allows you to create models by specifying parameters that can be accessed and modified later, providing more design freedom. It also comes bundled with some finite element analysis tools for engineering simulations.

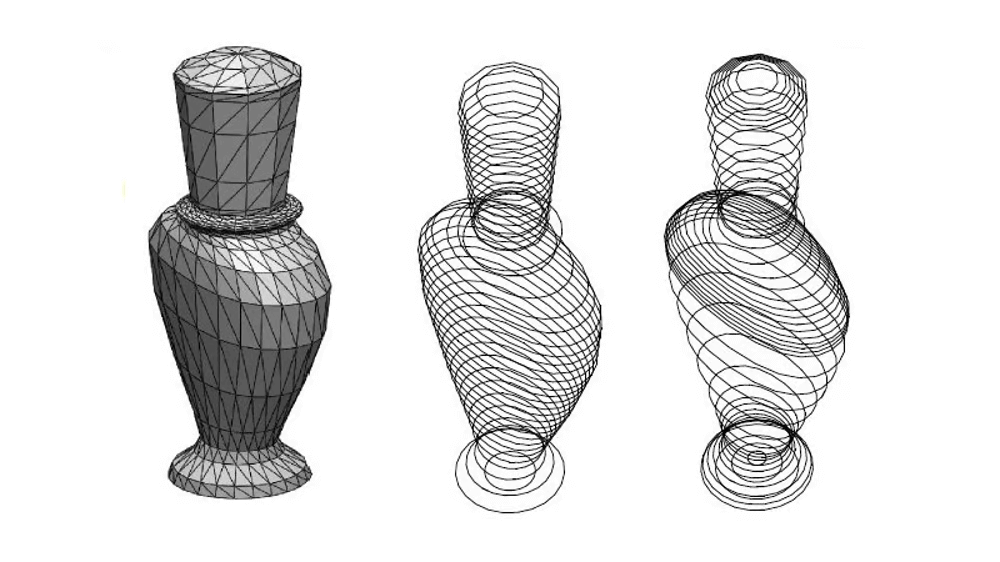

Direct modeling

Direct modeling is the opposite of parametric modeling in that it does not rely on strict geometry or dimensioning to modify your model. Like sculpting with clay, you can simply change the shape of the model by pushing or pulling it in any direction. This type of CAD software is primarily used to create organic curves in an aesthetic or artistic capacity.

BLENDER

Open source and developed by hundreds of contributors, Blender is a free yet professional 3D modeling tool for creating complex 3D models. It is one of the most powerful 3D printing software tools available, both for designing and editing meshes.

ZBRUSHCOREMINI

The free version of the widely used ZBrush software, ZBrushCoreMini , is designed with new users in mind, while giving them as much creative freedom as possible to sculpt whatever comes to mind. Although it is the free version of its predecessor, ZBrushCoreMini offers 12 different sculpting brushes, 8 materials and various functions to easily add fine details to your models.

STL fix

Sometimes you might come across a strange 3D printable mesh file that has some errors that trip up your slicing software or 3D printer. In that case, you'll need to use network repair software to fix the . Mesh repair is an essential companion tool to cutting because it helps refine the composition of the model by smoothing or filling holes and surfaces that would cause a cutting error.

Some 3D modeling tools, such as FreeCAD, SketchUp, Blender, and Fusion 360, to name a few, have meshing tools included. But in case they don't suit your needs or skill level, there are also some specially designed mesh repair programs. Below are a few of our top picks.

MESHMIXER

Autodesk Meshmixer is a free design tool that allows you to efficiently sculpt and repair meshes. It can analyze, automatically repair and modify networks. It is loaded with easy-to-use 3D printing-oriented tools, making it a top choice among 3D printing enthusiasts. It is also important to note that as of 2021, Meshmixer is no longer supported by Autodesk, but is still available for download and widely used in the 3D printing community.

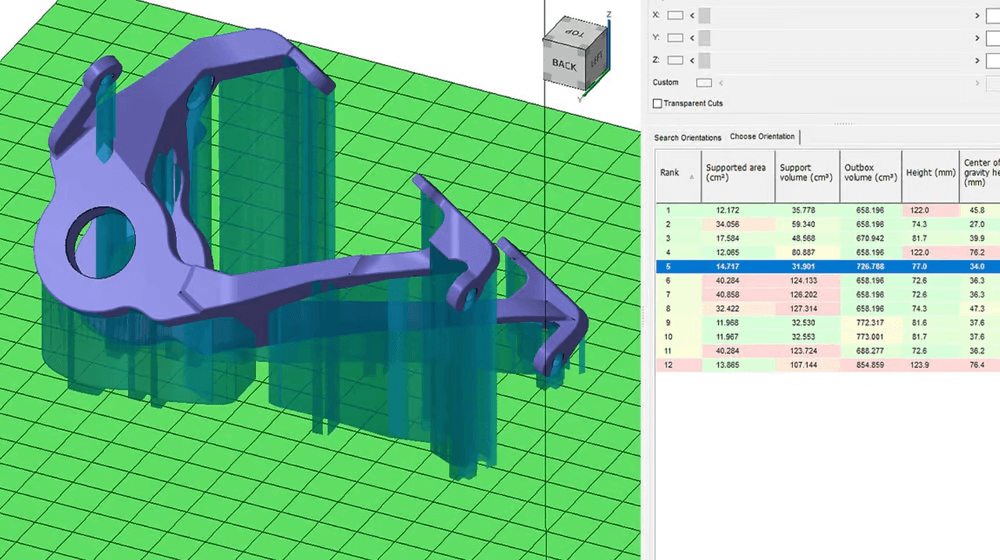

NETFABB

Autodesk Netfabb is a professional, commercial tool aimed specifically at additive manufacturing. It has many powerful tools for preparing and repairing 3D files for 3D printing, including automatic assembly of parts, automating printing tasks and creating simulations of the printing process. As of 2021, the tool has been integrated into Fusion 360, both of which can be downloaded for free with an educational account or a license for limited personal use. Netfabb's mesh recovery protocol is also integrated into some slicers, such as the PrusaSlicer.

Remote print control

If you do very "heavy" 3D printing, you may want to consider some print management software to control your 3D printer(s) and manage your print sessions. These typically include built-in 3D printer control and monitoring, file slicing, and print run, all in one platform to streamline the 3D printing process.

These programs are useful if you need to run unattended prints or want to control or monitor your prints wirelessly. To allow access to control your printer remotely (over a network), many print management software work with an optional Raspberry Pi or other Internet-enabled microcontroller connected to your printer's control board.

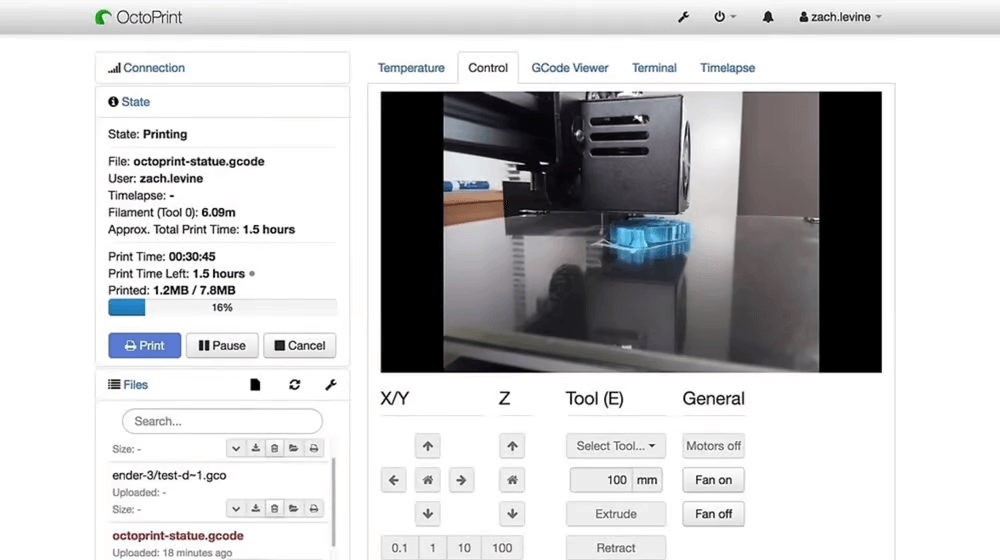

OCTOPRINT

OctoPrint, developed by Gina Häußge, is one of the most popular print management tools available. It's a web-based interface running on a Raspberry Pi connected to your 3D printer that allows for detailed printer control, monitoring, slicing and wireless printing. With a whole host of plugins available, it's an incredibly powerful tool for doing all your 3D printing in one place.

PRINTRUN

PrintRun, written by Kliment Yancev and currently maintained by him and Guillaume “iXce” Sequin, is another powerful print management tool. Like OctoPrint, it includes 3D printer management, slicing and release for printing. With so many settings and parameters available, however, it's not for the 3D printing novice.

G-code Viewers

Our last piece of optional but relevant software is a G-code viewer, which is especially useful in scenarios where you only have a G-code file to print. Most G-code viewers are free tools that allow you to simulate or visualize prints based on the 3D coordinate list contained in the file you upload. In case your slicer doesn't already have a G-code viewer, an external preview provides peace of mind by showing you how your G-code files will work.

G-CODE ANALYZER

G-Code Analyzer is a browser-based platform that not only visualizes your print, but can also calculate the time, average speed and total distance traveled during printing when you enter your printer specifications. During the visualization process, models are displayed in 2D from a top perspective. To the right of the UI is an interactive slider that shows a specific layer depending on where you drag it.

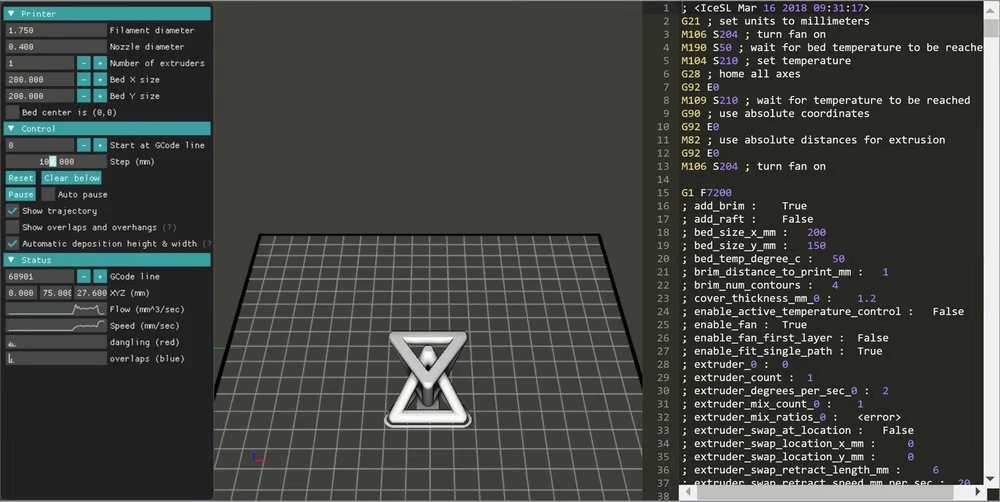

ICESL WEBPRINTER

WebPrinter is a G-code preview that is both online and downloadable, and both versions are free. The user interface simulates 3D printing as if you were physically watching your print in real life. During the simulation, WebPrinter also creates real-time graphs and charts that give you some information about print flow and speed.

More information

We've shared our picks for 3D printing software with you, but the learning doesn't stop there! We at 3MG Bonev Ltd. we can organize individual or group training for you, guide you to reach the level with which you can handle your daily needs in the field of Additive Technologies.

0 Comments