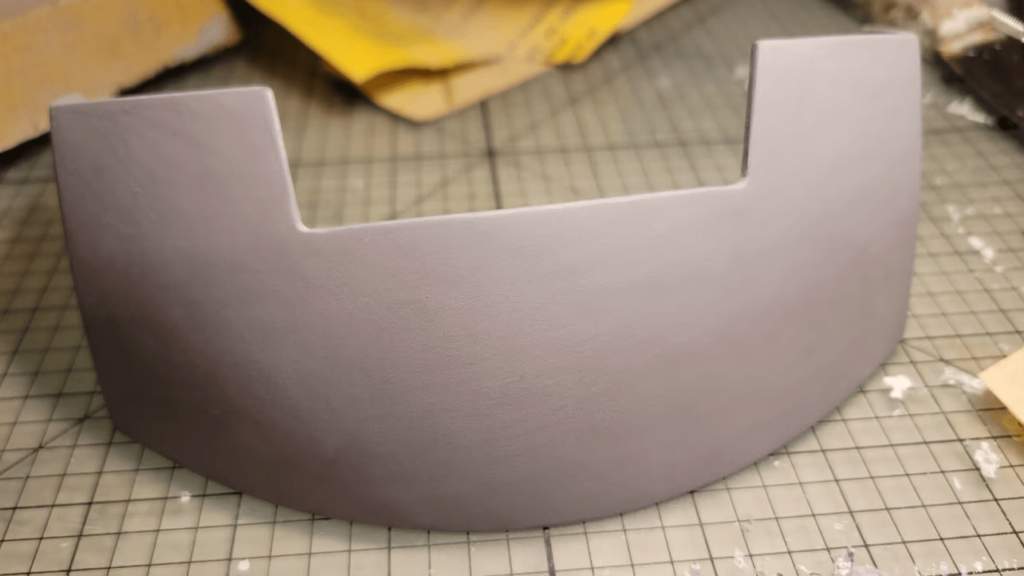

Sanding 3D prints is a lot of work, but it's worth the effort. Read on to learn how to achieve photo-ready 3D prints!

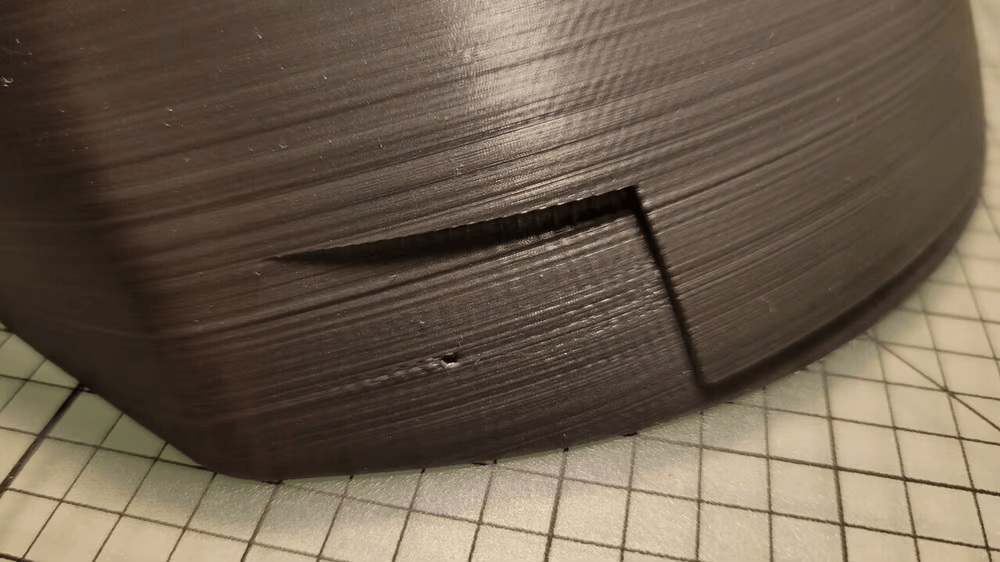

All production processes have limitations, as even machines cannot produce shapes as smooth or detailed as they are designed. The raw 3D printed part will not be perfect, so post-processing is almost always necessary. This is the step that ultimately leads to “Wow! How did you do it? ”Grinding is the most common post-processing technique in 3D printing, but it is also time consuming.

In the beginning, you may be overwhelmed by the thought of sanding for hours. Be sure to have techniques to get faster and more professional looking results. Grinding PLA has some unique challenges and helps you get started with smooth printing. In this article, we will discuss everything you need to keep in mind when grinding your 3D prints, as well as how to do it. So, roll up your sleeves and get to work.

How to print smooth parts

To avoid a lot of work later, it is best to plan in advance how you will print the parts so that they will be easy to sand. Everything from how you store the threads to the settings you choose in the slicer can affect how much sanding your prints will require.

PLA, like most plastics, is hygroscopic, which means it absorbs moisture from the air. Wet PLA passing through the printer nozzle leaves a rough, erratic finish. It also leaves strings of material behind. The new reels are delivered vacuum-packed and with a desiccant, so they are not a problem. However, reels older than a few weeks should be stored in a dry place or dried before printing.

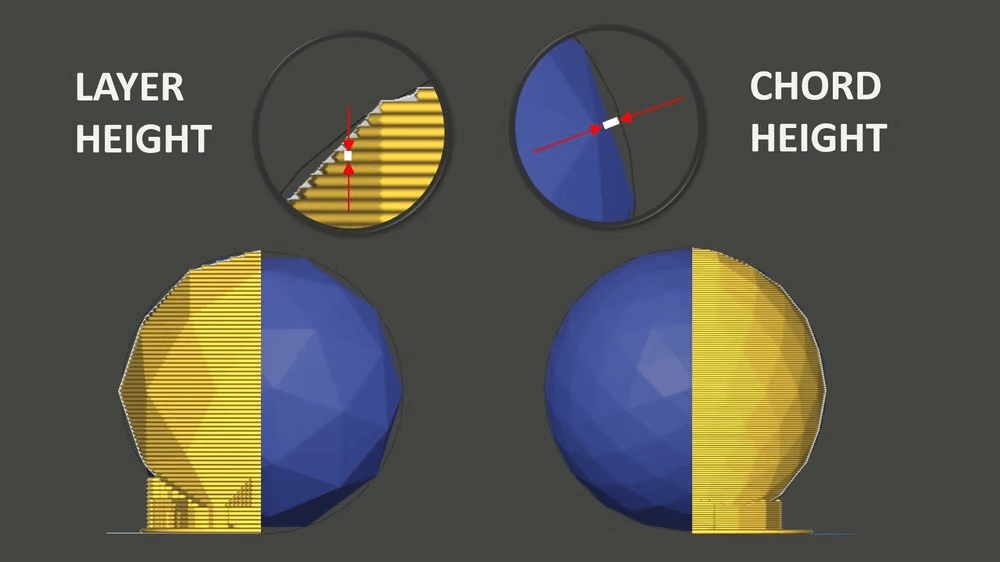

Even the way you export your 3D model from your design software can affect the surface quality of the final print. Chord height is the maximum allowable deviation that the STL file will have from the source model. A lower number means that the model will have a larger number of polygons, which reduces the faceted angles seen on curved surfaces. When exporting STL files, keep the Chord height much lower than the height of the print layer.

If you downloaded an STL file from a sharing site such as Thingiverse, you will not be able to change the Chord height. In general, STL files in repositories usually have a decent resolution, so this is not something to worry about.

Slicer settings (Slicer)

Once you get a smooth STL file, maintain momentum in the slicer. There are quite a few settings that can help reduce the amount of grinding required. Here are a few:

- The orientation of the press plays a role in surface quality. Supports are needed in the overhangs, which makes the surface very rough. If possible, print with the good side up so that there are no visible traces of supports.

- The height of the layer should be adjusted to the finer settings of your machine, within reason. A very low layer height can add a lot of printing time, but will result in a smoother finish. Shapes with vertical walls and flat tops are more forgiving with rough layers than angled walls or domed tops.

- The thickness of the wall is very important for grinding. It is good to have a little extra wall thickness in case you sand too deep. Otherwise, you can leave a hole or tear off pieces of thread. A thin wall will deviate as you grind, showing an imprint of the filling. Also, remember that you will grip the part tightly - a fragile part can easily break during operation.

- Print speed , if set too high, may cause the printer to vibrate, leaving marks on the fingerprint. So, slow down the machine acceleration settings to reduce vibration.

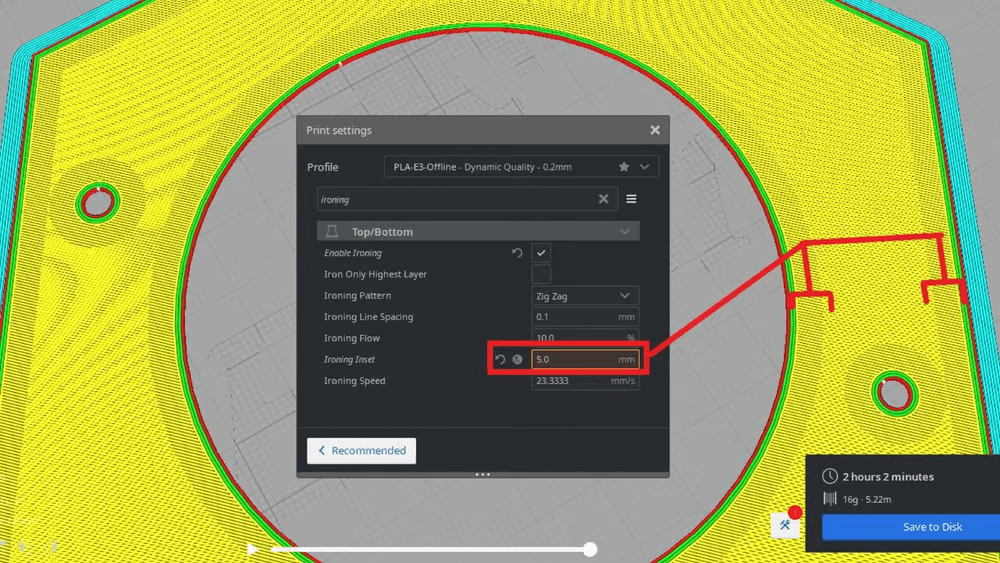

The unique cut features can also help achieve smoother 3D printing. Ultimaker Girl and PrusaSlicer offer a feature called "ironing" that smoothes the top layers of the print. When the printer nozzle completes the top layer, the high dots blur. You may need to experiment with the settings, but this can help smooth the top layer.

Why sand?

Even if you have done your best, sanding is still usually required to achieve superior coverage. But sanding can be a lot of work, so why do it?

- Safety and comfort: Removing sharp edges and rough surfaces is always important. PLA is not very sharp, but can be uncomfortable in wearing applications such as suits or dentures. Feel the whole part with your hands and remove everything sharp with rough sandpaper or a file. Doing this first facilitates aggressive sanding in the next steps.

- Precise fit: If you are assembling mechanical parts, precision is important. You want to keep shapes like flat and cylindrical. Shafts and bores need precise clearances based on their function, but depending on the accuracy of your printer, some adjustment may be required. Before and during sanding, test the adjacent parts and mark the areas to be removed, being careful not to go too far.

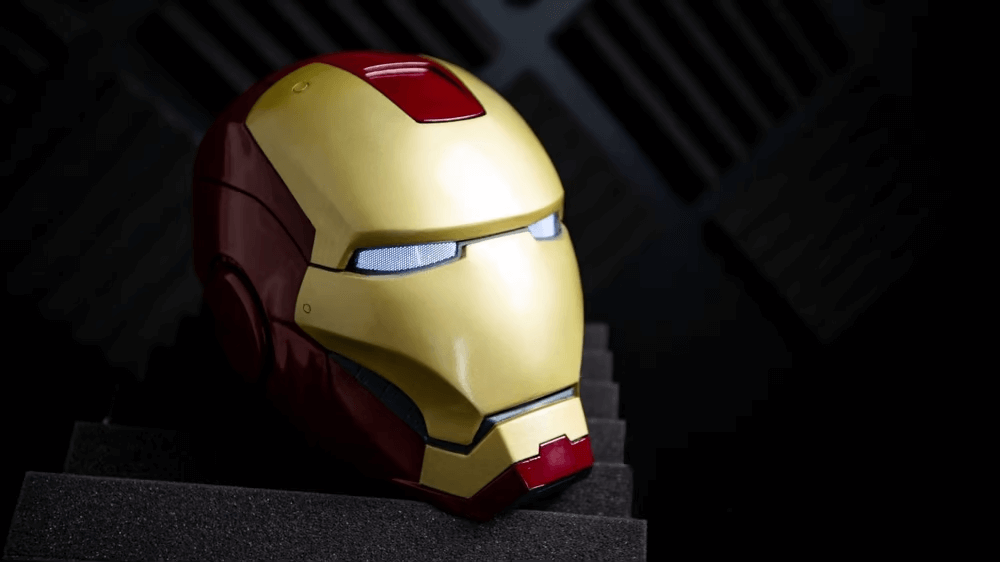

- Aesthetics: How a print looks is important, especially for functional parts such as film props or marketing demonstrations, but also purely for the pride of the workmanship. In all these cases, removing the layer lines is a priority.

What you will need

Tool Tango)

Whatever the reason for sanding, you will want to start with the quick removal of the material first. Thus, most of the shaping is done quickly.

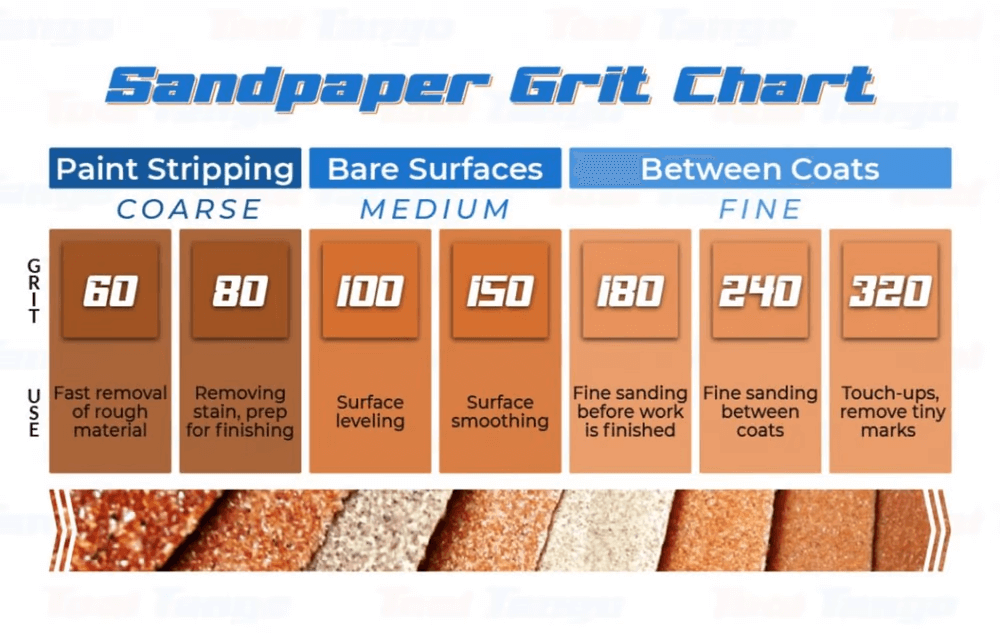

Sandpaper is available in different types of sand (roughness levels). The large grains are for quick removal of the material. The middle grains are for smoothing before priming. Fine grains are for preparation for dyeing. Very fine grains can be used between coats of paint. Extra-fine are for polishing and polishing after painting.

Cheaper products often have bad adhesives that cause sand to fall off the paper. Even worse is sandpaper with inconsistent grain sizes. A large grain on a piece of fine paper can leave deep scratches, which will return you to rough sanding. For this reason, avoid storing coarse and fine sandpaper together. It is also important to clean the part before replacing the finer grains of sandpaper to remove any remaining coarse grains.

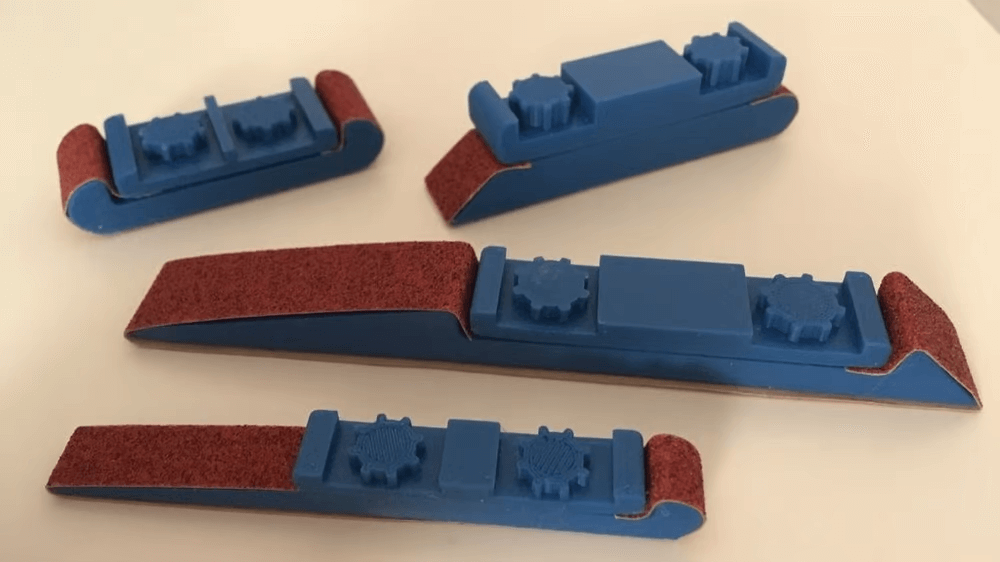

Make your own tools

The geometry of some parts may require specialized tools for sanding certain surfaces or hard-to-reach places. Fortunately, this does not have to be expensive, as there are many solutions. A sanding block, for example, can be created by wrapping sandpaper around a piece of hard material, usually wood.

Simply folding a piece of sandpaper is great for deep grooves and corners. Wrap sandpaper around the dowel to enlarge or smooth holes. Of course, you can also print your own sanding tools.

Equipment purchased from the store

With regard to the sanding tools to buy, the files are convenient for hard-to-reach places. PLA will not wear the files, but it can clog their teeth, so a wire brush for cleaning files is also good to have on hand.

Another good item to keep on hand is a glue towel, which is used to clean an object before priming or painting. All this sanding powder has to go somewhere!

ELECTRICAL TOOLS

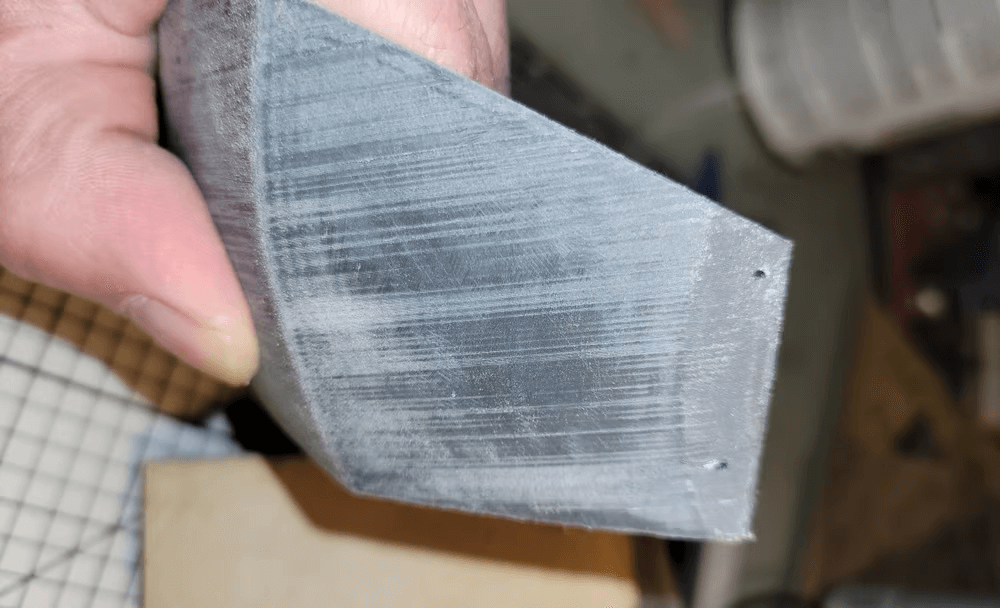

Power tools are great for quickly removing material over large areas. This can save a lot of time, but requires little practice. The friction will soften or melt the PLA after a few seconds if the pressure or velocity is too high, especially if the walls are thin or the part is small.

It is advisable to start with less critical areas until you feel how fast it heats up. Do not sand an area for long. If the part becomes less smooth while sanding, it becomes too hot. Blowing a fan can help, but the most important thing is to keep the tool moving.

OTHER MATERIALS

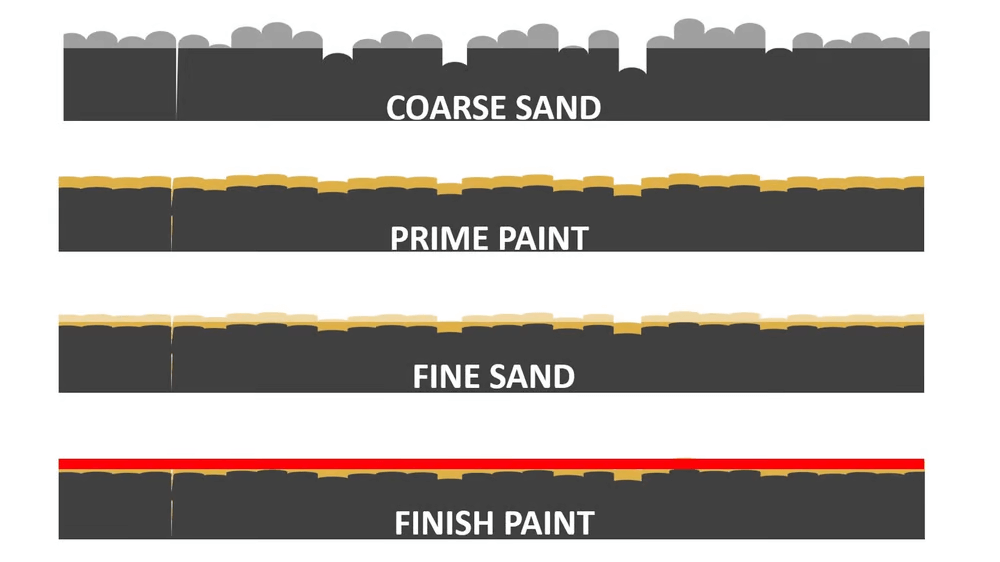

Fillers and primers are essential for hiding deep layer lines, voids and other low-grade defects. Larger gaps can be patched with wood putty or similar fillers, while primers are a type of porous paint that adheres well to the base surface.

There are several types of primers you need to know about. Brush primers cost less and are good for filling stains or very large projects. Spray primers are comfortable and do not leave traces of the brush.

Finishing technique

The printed surface of the part has tips and dents. Peaks consist of printed layers, backing material, printer artifacts, or STL nodes. Valleys are the spaces between layers and gaps caused by an interrupted flow of nozzles.

To smooth the surface, you will need to level the tips by removing material and lifting the recesses with filler or primer. An aggressive first pass with coarse sandpaper will remove almost all tops. Subsequent passes, each with finer sandpaper, will remove the scratches from the previous step.

Wet sanding can be used for finer surfaces. Using a little water helps to clean the debris and prevent sticking to the sandpaper, as the primer and fillers can stick to the sandpaper and clog the sand.

But most importantly: don't forget to always use a dust mask and eye protection when sanding!

Level of cosmetic completion

How do you know when you're ready? How do you determine the final level? Think about the end use and how big a defect can go unnoticed. The basic human eye can distinguish an element about 0.3 mm in size from a distance of 1 m. You can use this ratio to determine the minimum defect size for each use case.

To determine how much more finishing work is required, always check them in good light and the paint is completely dry. The paint shrinks as it dries, revealing imperfections.

Step-by-step summary

To apply what you have learned to your next project, use this summary as a guide:

- Use an STL file that is accurate enough for your use case.

- Print parts with optimized slicer settings.

- Before sanding, check the part for printing defects, sharp edges or rough surfaces.

- Start with coarse sandpaper or files to smooth out all dangerous edges and surfaces.

- Test the installation of all parts that need to be assembled by switching all moving parts through their range of motion.

- Using sandpaper, sand all aesthetic surfaces. Remove all the peaks down to the valleys.

- Use wood putty filler to fill any gaps, bare infill or other printing defects. Allow the putty to dry.

- Using sandpaper, sand all repairs you have plastered to remove excess material.

- Using finer sandpaper, sand all surfaces. Continue until all deep scratches are gone.

- Use a primer to paint parts with an even layer. Allow to dry.

- Check each part, with good lighting, for defects and visible lines on the layer.

- Sand the parts again with finer sandpaper, paying more attention to the problem areas.

- Prime each part again and allow to dry.

- Repeat the previous three steps until the parts meet your quality expectations.

- Now your parts need to be ready for painting.

Grinding alternatives

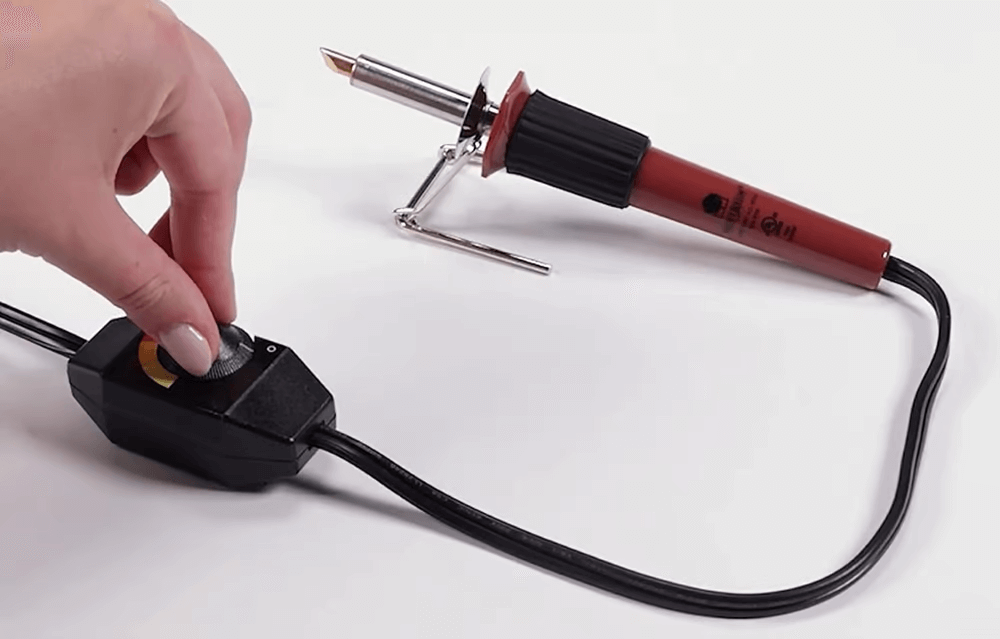

Now, if all this seems like too much work for you, there are several other methods to smooth out PLA. A wood engraving machine or soldering iron can be used to gently melt the outer surface, achieving smoothness with little effort.

Some of these other techniques can emit smoke and odors, so we recommend good ventilation. For example, epoxy or UV resins can be coated on the part, leaving a thick hard shell, but you do not want to breathe certain coatings for too long. After a few compilations you will find the right balance between time spent and quality of completion. Now start your next project and start making powder!

If you have any questions, do not hesitate to contact the team of 3MG Bonev Ltd. to help you.

And if you do not care to grind and / or other final activities for your projects, call us - we will do it for you!

0 Comments