Every technology exists to solve a problem or make our lives better – and 3D printing is no different. Before we dive into all the technical details, let's take a look at what you can do with a 3D printer.

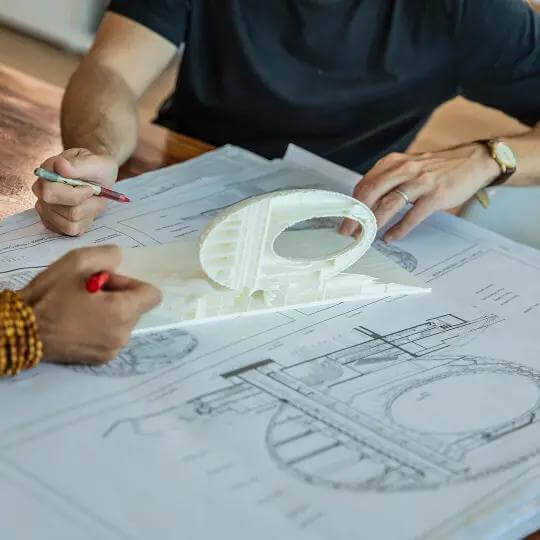

Prototypes

True to its origins as "rapid prototyping", 3D printing is still widely used for this purpose. With 3D printing, designers and engineers can print their digital designs and review them within hours.

There are different types of prototypes you can make with a 3D printer. Designers can create multiple early concepts to determine the direction of the product development process, or in later design stages create a realistic mock-up to evaluate the form factor—for example, how the phone feels in the hand.

And engineers can use different material options to perform functional testing on their prototypes, such as checking heat resistance or testing the design of a new part, or impact resistance.

What else can you do with a 3D printer?

Functional parts

Beyond prototyping, 3D printing is a powerful way to create functional parts and tools. Most plastic products are created by injection molding, a process in which molten plastic is injected into a metal mold where it solidifies into the desired shape. Although this process can only take a few seconds and is easy to repeat, it takes much longer to make the initial shape and only becomes cost effective once you make a large number of parts.

What if you only need a few hundred? Or do you need them by the end of the week? This is where 3D printing can help.

As 3D printers have become more reliable and capable of printing with a wider range of materials – from tough “glassy” or metal composites, to flexible rubber-like materials – short-term, small-batch production has become a realistic option.

3D printers give the manufacturer more control and flexibility. If the delivery of a component is delayed or there is a spike in demand for your product, the parts can simply be 3D printed so that production schedules stay on schedule. This isn't just helpful for manufacturing businesses, but it helped keep medics safe at the start of the COVID-19 pandemic when PPE and other supply chains couldn't keep up with demand.

Spare parts are common in production and packaging lines, where any problems and downtime can be very expensive. If a part can no longer be obtained or breaks down frequently and needs to be optimized, 3D printing means a replacement can be installed in a matter of hours.

Tools

A type of technically functional part, 3D printed tools are now so widespread that they can be considered a category of application. Manufacturers can create and test new or optimized tools whenever they want, as well as custom fixtures to make the manufacturing process easier and more repeatable.

Models for visualizing ideas

Besides designing and making products, visualizing concepts in 3D is another great example of what you can do with a 3D printer.

Applications include architectural models of new developments, medical models for planning surgical interventions or explaining procedures to patients, and visualizations for educational purposes.

Cost reductions and the development of more compact “desktop” 3D printers have also made the technology more accessible over time.

Would you like to receive more information and a free analysis on implementing additive manufacturing in your business?

Trust the professionals from 3MG Bonev Ltd. to enter the world of 3D printing. Staying competitive means getting your products to market faster than the competition. And that means prototyping faster and more efficiently to test your ideas and optimize your product. Contact us through the various communication channels we use!

0 Comments