Which 3D printer should I buy? There are a huge number of options to choose from, so let's narrow down the right choice for you.

Not so long ago, 3D printers were limited to industrial use, costing tens of thousands. These days, it seems like consumer printers are available on every corner, with more popping up every day. Such a choice comes with the luxury of lower prices, meaning you can pick up a decent printer for just the $200. The difficulty is in choosing the right one.

While we won't help you choose the specific printer for you here, we will point out some things to consider before buying a 3D printer: What type of 3D printer is right for you? How much should you spend?

To answer these questions and more, we've put together this post to point you in the right direction.

QUESTION #1: SHOULD I BUY A 3D PRINTER?

Before you start shopping, first think about the things you want to 3D print and how often you will do it.

If you want to try out the technology, you can always check in your area for a workshop before investing. Depending on your needs, a 3D printer can be expensive and have a steep learning curve. Talking to experienced 3D printer users will quickly help you figure out if the technology is right for you and maybe even take your first steps in learning how to use it, as such spaces usually have machines that members can use – try before you buy!

If you only need one part or a few parts printed from time to time, you may be better off using a 3D printing service such as us at 3MG Bonev Ltd. – Your 3D printing solution!

But let's assume you're buying a printer and continue with the questions.

QUESTION #2: WHAT TYPE OF 3D PRINTER SHOULD I BUY?

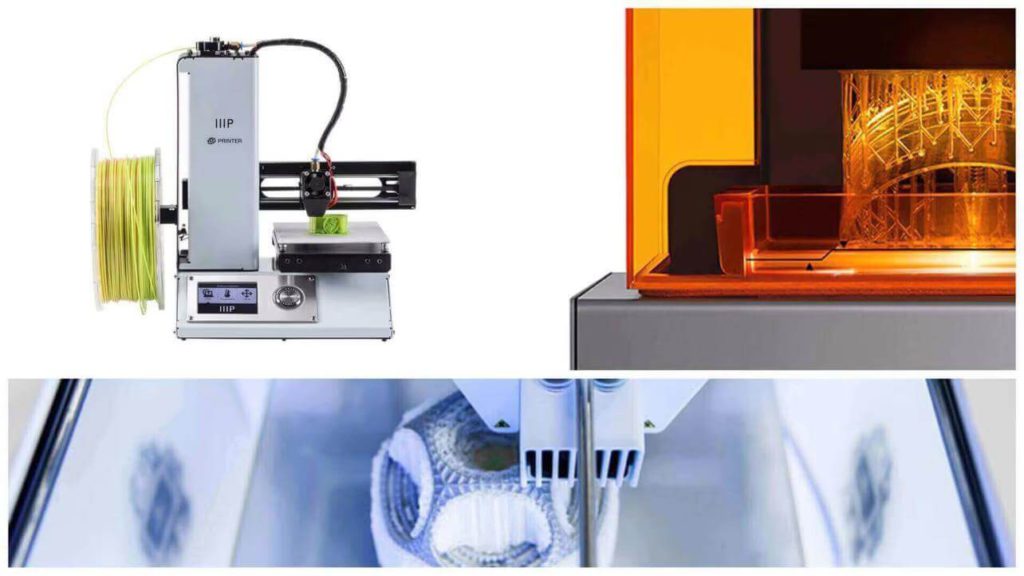

There are currently 11 major 3D printing technologies, of which only a handful are related to home 3D printing and desktop 3D printers.

You probably don't want to invest in a $100,000 3D printer capable of sintering metal, so instead we'll turn your attention to two branches of 3D printing technology, fused deposition modeling (FDM) and bath polymerization (usually SLA, DLP, or MSLA).

Should I buy an FDM 3D printer?

Fused deposition modeling (FDM) is the most common printing method used in desktop 3D printing.

A thermoplastic filament is heated and extruded through a nozzle, depositing the molten plastic in layers on the print bed. These layers merge, build up throughout the print, and eventually form the finished part.

Such 3D printers are a cost-effective means of product development and rapid prototyping in small businesses and are a great educational tool in schools. For domestic use, they can quickly produce simple spare parts, and many are used to create complex decorative elements and even costumes.

There are many advantages to using an FDM 3D printer. First of all, the choice of materials is huge, they are cheap and have a wide variety of colors. These printers work seamlessly with engineering grade plastics. They are easy to use, but can require a lot of maintenance if something goes "wrong".

We keep track of the best FDM printers for home use, making it easy to find the right printer for you.

Should I buy a resin 3D printer?

Resin 3D printers use bath photopolymerization, which is the process of curing a liquid polymer by exposing it to ultraviolet (UV) light.

The desired pattern is constructed layer by layer in a bath of liquid photopolymer resin by shining ultraviolet light through the transparent bottom of the bath, selectively curing the resin. Fixed to a platform that is repositioned after each layer, the object is pulled through the pool of resin.

Stereolithography (SLA) is often used as a synonym, but also in its own right - along with MSLA and DLP - a subcategory of bath polymerization, differing only in the light source used.

Resin 3D printers can render extremely fine details, often creating objects with a relatively smooth surface. The technology is generally faster than FDM and can somewhat produce stronger objects due to increased layer adhesion.

There are fewer budget SLA machines than FDM 3D printers – resin printers are often used in a professional context – but prices have dropped dramatically in recent years, making this technology now more widely available.

QUESTION #3: HOW MUCH SHOULD I SPEND ON A 3D PRINTER?

Exactly how much you spend on a 3D printer will be based largely on your personal situation, of course. You can buy for 200 $. Of course, you can go above that price if you choose to look for more professionally targeted systems ( 6,000-7,000 $ ).

That's a big range to choose from, but we can narrow it down by looking at a few key considerations. For simplicity, we'll compare FDM printers that demonstrate these considerations below to get our point across.

Size

The price and size of the 3D printer are extremely relative. Large printers are great for getting more volume to work with, but a larger gantry can also open you up to significantly more shake and result in lower quality prints. Think about the space you'll really need for a 3D printer, if it's a smaller volume you can save yourself some money and possibly some annoyances.

Characteristic

There are plenty of options to upgrade your 3D printer just right, and deciding what you want beyond the basics—and whether you're comfortable getting your hands dirty to upgrade some features later—can help you settle on the right purchase price.

A few commonly looked at features include: bed leveling, connectivity, user interface, motion systems, extruder category, and so many other choices that you can get confused. The bottom line is, pick a few features that are important to you and prioritize them. If you're comfortable adding simple things later, like BLTouch for automatic bed leveling, or changing things a little more drastically, like an extruder conversion, skip those features when you buy.

For example, we're fans of self-leveling beds with sensors to automatically level the bed. It can be difficult to convert a non-fixed bed efficiently, so we might as well start our budget where good fixed bed printers start.

Quality

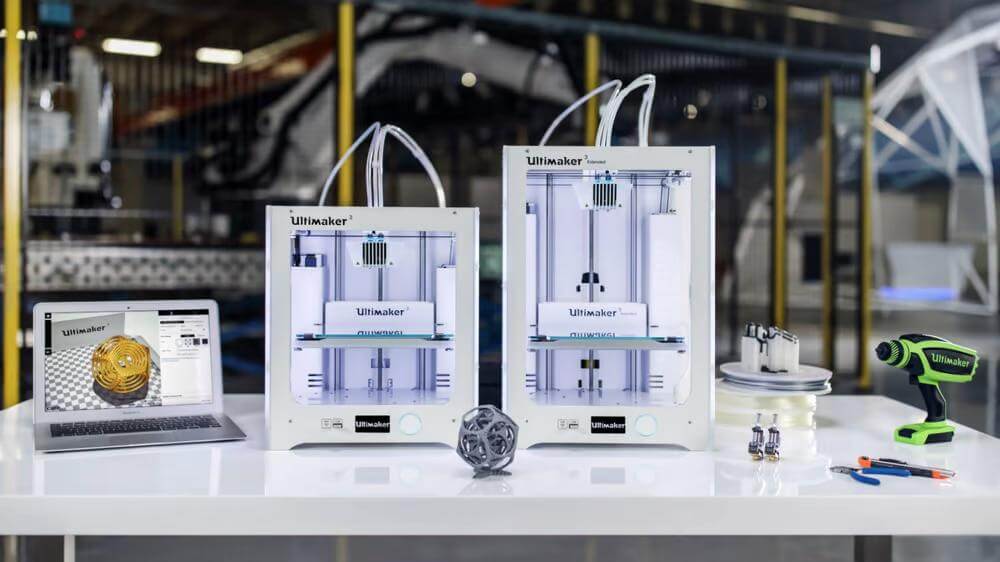

Sometimes products (we're referring to the choice of 3D printer) are hard to quantify exactly, and if you're not an engineer, a product that "just works" can seem a bit like magic. If you don't want to tinker with your machine and just want good results, you should choose a system that is known to produce high quality parts and perform reliably.

In our opinion, the category of high-quality "no fuss, no fuss" 3D printers in the FDM category starts with Prusa Research's original Prusa i3 Mk3S+ and goes up to higher-priced systems aimed at more professional users, such as the Ultimaker S3 or Ultimaker S5 - with plenty in between, of course.

If you want to buy a 3D printer today, the choice is yours, and you can get help and guidance from us by contacting us through the various communication channels or visiting us on site at our office in the city of Yambol, George Papazov St. No. 14, office 407.

0 Comments