What is additive manufacturing? How it works? Learn the basics, advantages and disadvantages.

Additive manufacturing (AM), also called professional or industrial 3D printing, is a relative newcomer to the manufacturing industry. Nevertheless, it quickly reached commercial viability and has one of the widest ranges of application of any production method.

Today, additive manufacturing is a $7 billion industry that has found a home in the manufacturing facilities of aerospace and automotive giants, in the military and hospitals, in architectural and industrial design firms, in the shops of small manufacturers, and in the laboratories of research institutions and universities .

Former US President Barack Obama, in a national address, called 3D printing a technology that has "the potential to revolutionize the way we do almost everything." The European Union is funding several projects to advance 3D printing as the future of sustainable manufacturing, while new additive manufacturing centers are opening in Asia.

No matter what line of business you are in, additive manufacturing can be the better choice for producing products, parts, tools and prototypes that are more efficiently designed, lighter, more economical, customized and manufactured faster than molding, milling, joining, sculpting and shaping in virtually every industry.

Additive manufacturing also allows you to recover production of your products and parts from distant sources and overcome supply chain disruptions, eliminate inventory that may never be used, and print on demand exactly what you need. you need now

Let's take a look at what additive manufacturing is, why governments and industries are investing millions in it, and how it can help your business innovate and thrive.

Basics, pros and cons of additive manufacturing

Additive manufacturing, as the name suggests, adds material layer by layer until the desired shape of the part is achieved, effectively creating the part from "nothing". This is done using various technologies. Some additive manufacturing methods extrude plastics from a nozzle, some use light to solidify liquid plastics, some use lasers to bond particles of powdered material into solid form, and there are many more approaches. But what they all have in common is that they "add" material in layers, rather than "subtracting" material from a larger piece.

Although the terms additive manufacturing and 3D printing are often used interchangeably, this is not exactly correct. 3D printing is a major step in the additive manufacturing (AM) process, but AM encompasses much more, from the initial digital part design to polishing and other post-processing steps. In other words, it covers all the processes needed to produce objects, not just 3D printing.

The exact components in the AM process depend on the type of technology, but in general, all AM technologies offer the following advantages over traditional subtractive manufacturing.

Creating previously impossible shapes

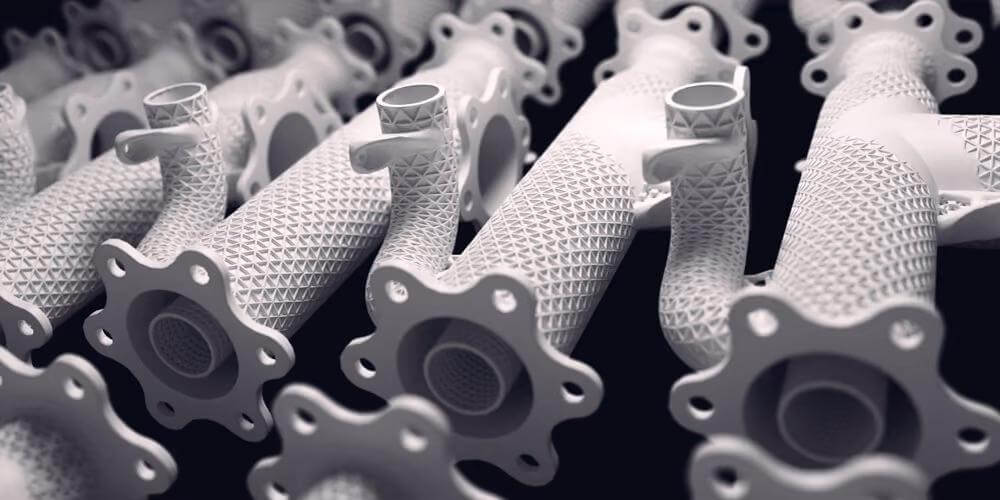

Additive manufacturing (AM) can create shapes and parts with complex geometries that traditional manufacturing cannot create, such as complex internal channels, lattice-filled closed spaces, and densely interconnected parts. This capability has revolutionized product design, allowing engineers to rethink how parts can be improved with new shape possibilities.

Crafting without tools, molds or dies

A 3D printer can make virtually any shape without changing or adding tools or parts. It can even make a batch of different shaped parts at the same time. This advantage means that each printed part can be unique and personalized.

Ecological process with almost zero waste

Because 3D printers add material instead of removing it, there is very little or no waste from the process. Often the excess material can be reused to make the next part. 3D printers can use post-consumer plastic as a material to create new products, offering an attractive recycling solution. Additive manufacturing is a particularly attractive method when using expensive materials, such as titanium or some industrial polymers, because you need fewer raw materials to create a product.

Remove the assembly of parts

For the production of assemblies with moving parts such as an engine block or gearbox, the parts are individually manufactured and assembled. With additive manufacturing, assemblies can be printed in a single assembly, thus eliminating time and labor, and reducing the introduction of errors or weaknesses during the assembly process. This is especially important for aerospace components, such as rocket fuel injectors, which can be 3D printed in one piece without vulnerable seams.

On-demand production reduces inventory

The ability to 3D print parts quickly and as needed eliminates the need to stock dozens or hundreds of spare parts that may never be used. Businesses are often forced to order multiple parts and stock minimum quantities when they only need a few to overcome the economies of scale limitations of modern manufacturing.

In-house manufacturing eliminates supply chain vulnerabilities

In traditional manufacturing, a business may have only a handful of suppliers for parts and products. This leaves them open to supply and demand price pressures and supply disruptions caused by everything from geopolitics to pandemics. In-house production eliminates dependence on external suppliers and polluting delivery.

Economical unique and personalized products

In traditional manufacturing, creating 100 similar products is often cheaper than creating one unique product. This is not the case with additive manufacturing, where each product or part can be unique. This gives an advantage to businesses that rely on offering custom-made products, such as custom sports equipment. Customized and unique products are also critical in the healthcare industry, where patient-specific prostheses and implants have been shown to improve outcomes.

Low barrier to entry

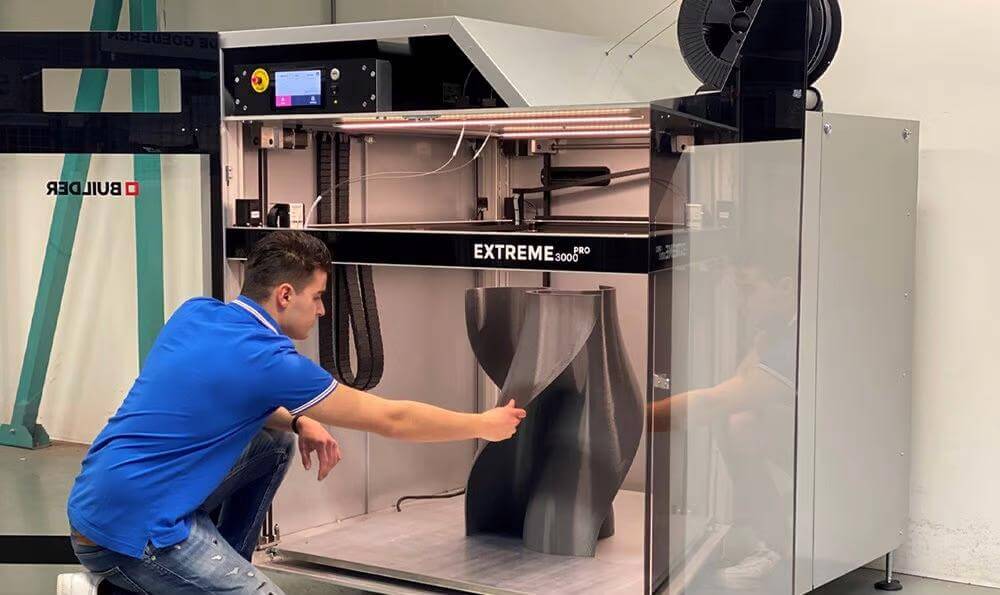

Professional 3D printers start at around $10,000 and are largely automated, making in-house production possible for a vast number of businesses that once relied on outsourcing. For example, small manufacturers can now 3D print their own gadgets, architecture firms can now 3D print their own models, industrial designers can now 3D print their own prototypes, and hospitals can now 3D print their own medical models.

Fast, economical spare and old parts

Many older machines, from classic cars to unique pieces of equipment, end up on the scrap heap because critical replacement parts are either no longer available or too expensive to manufacture. Additive manufacturing eliminates this problem with its ability to quickly print any part in any shape. The military, for example, widely uses AM to ensure that older equipment can remain ready.

Disadvantages of additive manufacturing

Additive manufacturing is undoubtedly a revolutionary manufacturing technique, but some challenges remain:

- Difficulty in scaling production to mass production level

- Limited print sizes with most 3D printers

- Some technologies and/or materials require some light post-processing

It's worth noting that AM technology is constantly advancing by leaps and bounds, with printer manufacturers and developers coming up with new solutions to existing production problems.

0 Comments