Our guide to making decisions about buying a 3D printer for your business covers everything you need to know about the technologies, materials and brands – in six steps.

With hundreds of industrial 3D printers for business and manufacturing, it's not easy to find the best one for your needs. Whether you're buying your first printer or your tenth, evaluating the latest technologies and companies can be challenging. Here you will find independent and unbiased guidance on everything you need to choose the right professional printer.

The first step is to understand your needs, then understand 3D printing technology, and then narrow your search to select manufacturers. You should also request and evaluate sample prints, understand the factors that go into cost, then build your business case for senior management to make the investment.

Step 1: Establish the business case for purchasing a 3D printer

Before you dive in who printer to buy, find out why you want one. What business needs will 3D printing solve, what strategic goal will 3D printing help your company achieve, or what new opportunities does 3D printing offer your business? If possible, tie these needs to your company's overall strategic plan and detail them clearly in a 3D printing proposal that is designed to include company management. To clarify your goals for purchasing a printer, consider these questions.

Do you want a 3D printer:

- to reduce prototyping or tooling costs?

- to speed up prototyping iterations or print production parts?

- to manufacture spare parts on site, on demand?

- to achieve efficiency in your overall production process?

- gain a competitive advantage by bringing new products to market faster?

- to print unique parts with attributes that cannot be produced in any other way?

- to save on material costs or material waste?

- retain your own design developments or manufacturing intellectual property?

- offer customers a customized product (eg in healthcare or consumer products)?

Knowing what business needs your printer will serve is key to establishing your printer selection criteria. But think ahead—along the way, you may find printers and materials that can help you with problems you didn't know you had, and open the door to new possibilities you hadn't considered.

To further determine your needs, it's helpful to find companies that face the same printer-buying challenges you're facing now. Case studies are a great way to learn how similar companies made a buying decision. A good place to find case studies is on manufacturers' websites, although they can be a bit one-sided.

Hire a 3D printing consultant

Of course, you don't have to do this alone. There is a growing market of 3D printing consultants, in addition to printer distributors, who offer expertise to guide you in assessing your needs and evaluating options.

Major printer manufacturers are launching consulting subsidiaries, such as Additive Minds 3D Printing Consulting from EOS and AddWorks from GE. Additionally, other business consultants offer supplement manufacturing experts as well as some useful industry research and summits.

A number of smaller, independent consulting firms staffed by former 3D printing industry veterans are also creating their own niches in additive manufacturing consulting, specializing in sectors (from healthcare to automotive) or applications (prototyping, metal spare parts and etc.).

Step 2: 4 things to know before buying a 3D printer

The technology, materials and software behind professional 3D printing are constantly evolving. Even if you have a solid knowledge base, refresh yourself with the latest developments.

1. Types of 3D printers

You may not yet know which type is right for you, so take a look at the different types of 3D printing technology.

2. Types of materials

From titanium to paper and everything in between, the range of materials you can 3D print is vast and growing every day. Find out which things are most often printed with which material. Also learn about the overall cost of materials, which can vary widely, and whether you'll want a printer that accepts third-party materials or will only print with manufacturer-specific materials.

3. Types of digital design and printing software

You may already be familiar with the range of software used for digital design, from AutoCAD to SolidWorks, but 3D printing has several unique applications and file formats to familiarize yourself with if you want to get the most out of your prints.

4. The best professional and industrial brands for 3D printers

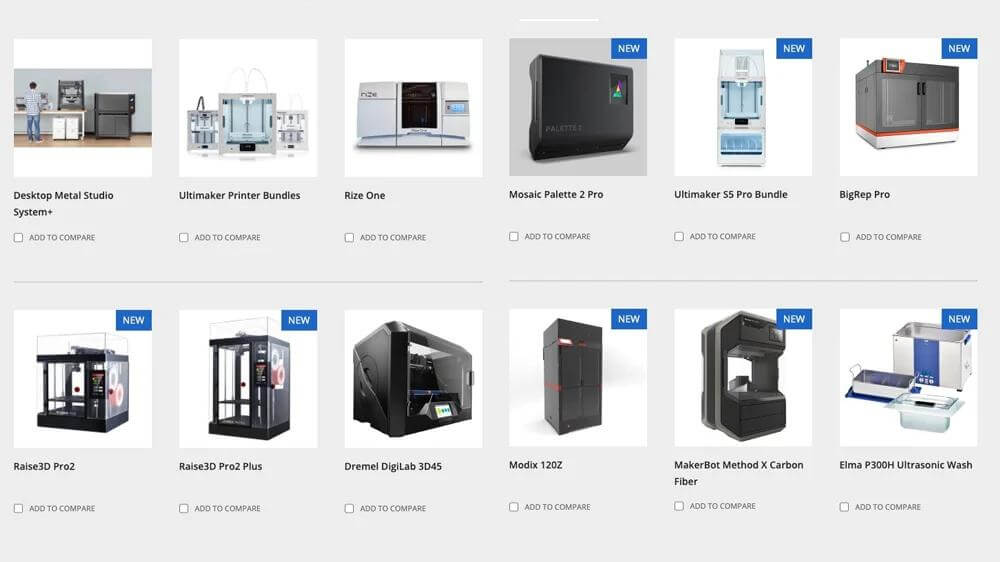

It's not as easy as it used to be to distinguish a consumer 3D printer from one used in a business or manufacturing environment. Many popular consumer printer manufacturers, including Ultimaker and Formlabs, have made the transition to professional markets while maintaining their ease of use. At the same time, advances in technology have allowed powerful printers to take up less space. So the bottom line is: keep your options open.

Some industry reports draw a line at $5,000, with anything below that not qualifying as an "industrial" machine, but that can be misleading. Labels such as industrial or professional do not reflect actual industry standards, capabilities, or feature levels, so feel free to be skeptical of their application.

If you narrow down your printer search using detailed criteria for what you need, you're likely to find a wide range of printer prices and from a long list of manufacturers.

Browse hundreds of printers at the trade show

You'll find all the major 3D printer brands on display at key additive manufacturing trade shows in the US, Europe and Asia. The largest event, Formnext, in Frankfurt, Germany, offers Excel downloads to its exhibiting manufacturers.

There are specialist publications, with unbiased and unsponsored reports on the best printers. They can help you narrow down your search and walk into a trade show already armed with information.

Step 3: How to request a sample stamp that matters

It's not always possible to see a large industrial machine in action without visiting the manufacturer, one of its customers or a trade show, but you can always ask for sample prints.

Ask manufacturers to print a sample part that represents your typical printing needs. You may be limited in size, but be sure to request a print sample that accurately reflects the complexity of the parts you intend to print and the desired final material and finish. If you are considering different models from the same manufacturer, request the same stamp from both machines (where possible).

If you already have a digital version of your part as a CAD model, you're all set. If your part does not exist digitally, you may need to hire an industrial design firm to scan your part, then create a digital file.

Ultimately, the manufacturer should provide you with a report to accompany your sample stamp, detailing exactly how long the part took to complete, what additional machining (if any) was done, and how much material was used. This information will help you estimate 1) how many printers you will need to meet your production goals, 2) how much material costs you should budget for, and 3) what additional equipment you may need to invest in.

Test your sample part

Review functionality, weight, feel, strength, and any other feature critical to your needs. Also share it with the staff who would be working with him for feedback.

If you have sample parts from multiple suppliers, compare them side-by-side and subject them to the same tests and evaluations.

Step 4: How to get management buy-in

Documenting your business case for 3D printing and presenting it to management is a time-consuming but essential task if you want to secure funding and support from decision-makers. If the owners of your company are not on board with the decision to purchase a printer, it may turn out to be a wasted investment in time and effort.

Your business report or presentation should include:

- Which problem/s or opportunities will 3D printing address in your company?

- The short-term and long-term benefits (such as faster time to market for new products, improved products and customer satisfaction, shorter supply chain, reduced inventory, etc.).

- Total costs including initial equipment, training, software, maintenance, materials, etc.

- A timeline of how long it will take to launch and the expected ROI date

Real-life examples strengthen your business and make it more relatable to management who may not be tech-savvy. Also, cite industry research.

If senior management is skeptical about the viability of 3D printing in general, point them to some scientific papers, one of which says, “Additive manufacturing has the potential to shake up not just individual industries, but the manufacturing sector as a whole. After all, a technology that engineers once derided for its slowness could become a dominant force in the economy. Now is the time to take it seriously as an option for large-scale commercial production. "

Step 5: Understand the hidden costs

Since the cost of a 3D printer is a major determining factor in your purchasing decision, it's important to know exactly how to calculate total costs. Keep in mind that the sticker price of your machine is only part of the equation.

When it comes to estimating the size of your final investment, consider the costs of:

- the printer

- materials, including whether you are involved in purchasing materials from the manufacturer or may purchase materials from third parties

- additional equipment required, such as a furnace for sintering metal parts or a station for washing and curing resin parts

- additional equipment such as a print monitoring system

- production space that may require special ventilation, sinks, tables, etc.

- software subscription in addition to the standard design and cutting programs, which may include incentive software,

- training staff including designers, engineers and machinists

- purchase and maintenance which may include travel costs if the distributor is far away

Materials can greatly increase your 3D printing budget. It's common to underestimate the amount of prints you'll make for a number of reasons. First, quite a bit of experimentation will be required to achieve a final satisfactory print. Additive manufacturing is a complex process involving many variables. Even if your digital design is optimal and you've tested it with simulation software, small inconsistencies in surface finish or materials can affect the final print. Also, unpredictable effects can always occur during the printing process.

Talk to the printer manufacturers about the extent of damage to their machine.

The other reason to underestimate your material costs is that you may find that 3D printing is useful for more applications than you first thought. It is not uncommon for companies to purchase a 3D printer for prototyping and then realize its benefits for end-use parts such as tools and fixtures, or even production parts.

Fortunately, the prices of industrial 3D printers are coming down as more companies enter the market. Keep in mind that price is not always a reflection of quality, so evaluate across a wide range of machines.

Step 6: Where to buy?

During your printer decision, you most likely worked directly with manufacturers. But at some point they can direct you to your local distributor who will be your point of contact for purchasing, installation, training, support, supplies, etc.

For larger machines, you may have a small selection of distributors, so it's important to know what to expect from them. For example:

- What is their experience with the machine?

- How long will you wait for the initial installation?

- Do they offer training?

- How quickly can they get someone to you for repairs?

- Will they bundle other items with the printer (software, post-processing equipment, training) to offer a better deal?

- In many cases, a printer manufacturer will have various distributors that specialize in a particular industry, such as higher education, dentistry or hospitals, that require special expertise.

If your company or government procurement agency requires multiple bids for major equipment, the printer manufacturer will invite several of its distributors to bid on the same bid. Although manufacturers give their distributors the same price, distributors may choose to reduce their profit margin or bundle other items or services to improve their offer.

In addition to financing, leasing instead of buying is also an option from many manufacturers today.

0 Comments