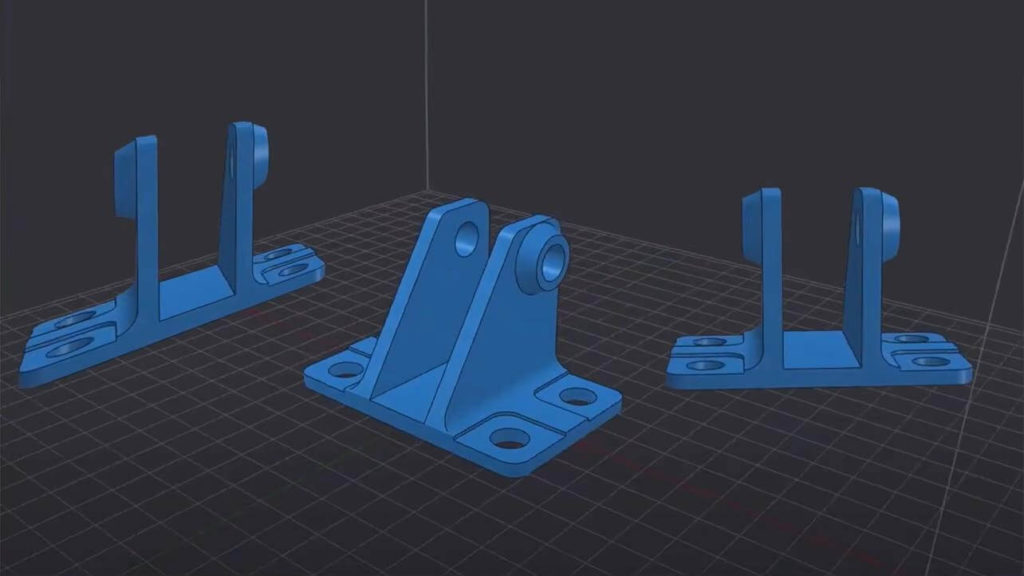

What is the cheapest and fastest way to produce 50 simple brackets? We asked traditional manufacturers and manufacturers with 3D printers for quotes, then compared it to buying your own printer.

Whether you work tirelessly in an industrial design company or start a home business, or just live and enjoy your life, sooner or later you will find you need some custom parts and there is more than one way to get these parts from your paper project in the palms of your hands.

There are a number of online manufacturers who are willing to take a model of your part and reproduce it in a variety of methods. But not all manufacturing methods are created equal.

Two of the most well-known and traditional methods are CNC machining, which involves taking a block of material or a "blank" and then milling from the block to produce the part, and the other is injection molding, which requires making a die from the part. in advance, usually by CNC, and then this form can be used thousands of times before having to make a new one.

The 3D printing methods we will consider here are FDM, SLA (stereolithography) and SLS (selective laser sintering).

FDM uses plastic filament to print and is available in a wide variety of materials, depending on the service. SLA generally refers to resin printing, where a tub of clear base filled with resin sits above the projector screen, which uses UV to harden the liquid resin and then peels away from the screen layer by layer. Several types of resin are available for different use cases, but parts tend to be more brittle unless a specially flexible resin is used. Now, SLS uses a type of powder that is applied in thin layers over the entire build area, then that layer is "hit" with a laser to sinter it to the main part, and then repeated with an entirely new powder layer.

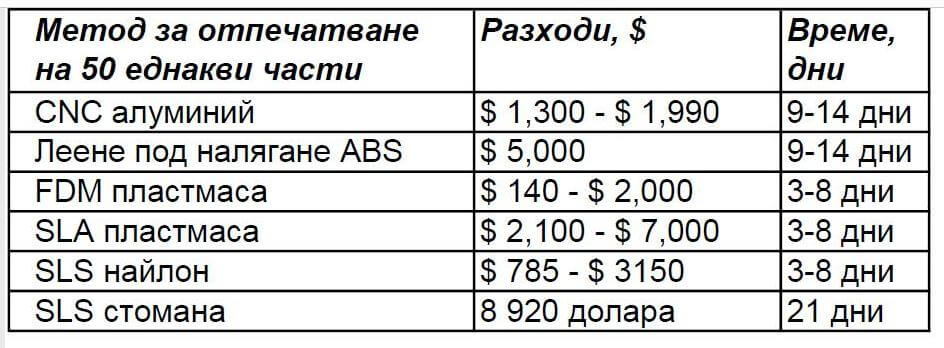

Method - Cost comparison

So now that we have all the methods laid out, we can look at the costs. All the estimates we have for production come directly from the manufacturers. We have sent a part for offers. We have chosen a relatively simple product that can be produced by all methods. Of course, there are parts that would be extremely difficult for one method compared to others, but that wouldn't be fair. So we got quotes for this part in lots of 50.

From a 3D printing perspective, FDM estimates are limited to around $2,000. Again, this is for 50 pieces. The lowest bid was $140 for the entire lot. SLA came in significantly higher than FDM at $2,100 the lowest and up to $7,000 the most expensive. The SLS ranges from $785 for the lowest to $3,150 for the highest.

On the other end of the manufacturing spectrum, we have $1,300 to $1,990 for CNC-aluminum and around $5,000 for die-cast. Injection molding is unique in that we break it down, we're looking at $4,800 for the tooling and $300 for the lot of 50. If we want to produce more, of course, that will adjust accordingly.

We also had one "crazy" supplier where the quote to get the aluminum parts was $21,545. It's good to get at least a few offers every time you search just because of that randomness. Steel, on the other hand, from the same manufacturer, was only around $8,920. He didn't specify which method he used to make these parts from these materials, but I'm guessing it's closer to SLS than CNC.

Another thing to keep in mind when dealing with these manufacturers is the turnaround time. Estimates were around three to eight days lead time for 3D printed parts and up to two weeks for CNC and injection molded parts and then shipping time.

Outsource vs. Buy your own printer

Thousands of dollars sure seems like a lot for a 3D printer. Why spend that money when I can have my parts made elsewhere and shipped to me for less? On the face of it, this is the much better option, but there's a lot more to consider than those dollar signs.

We found that 3D part printing can be cheaper and faster than traditional production, but now, let's look at another scenario: What if I want to make the parts myself?

First, you need the machines to make the parts, and we'll just assume you already have the knowledge or someone in your organization knows how to use it. For most capable CNC machines, you would be looking at a five axis machine versus a three axis machine. Now, for a five-axis machine, you'd be lucky to find a decent one under $100,000. An injection molding machine can cost as little as $10,000 and as high as $2,00,000.00, but molds don't come out of thin air. So there is usually a CNC machine for the mold and then the injection molding machine. So these costs will be combined - about $ 110,000.

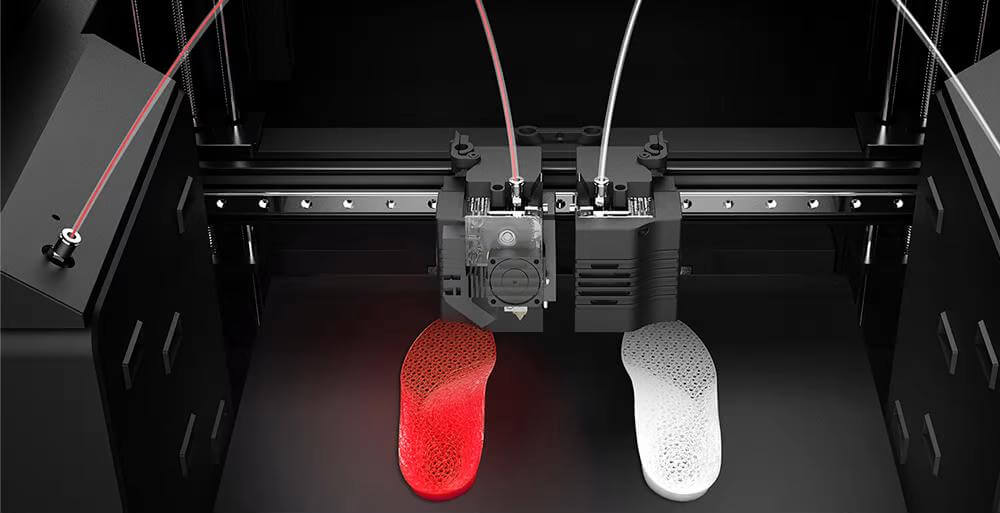

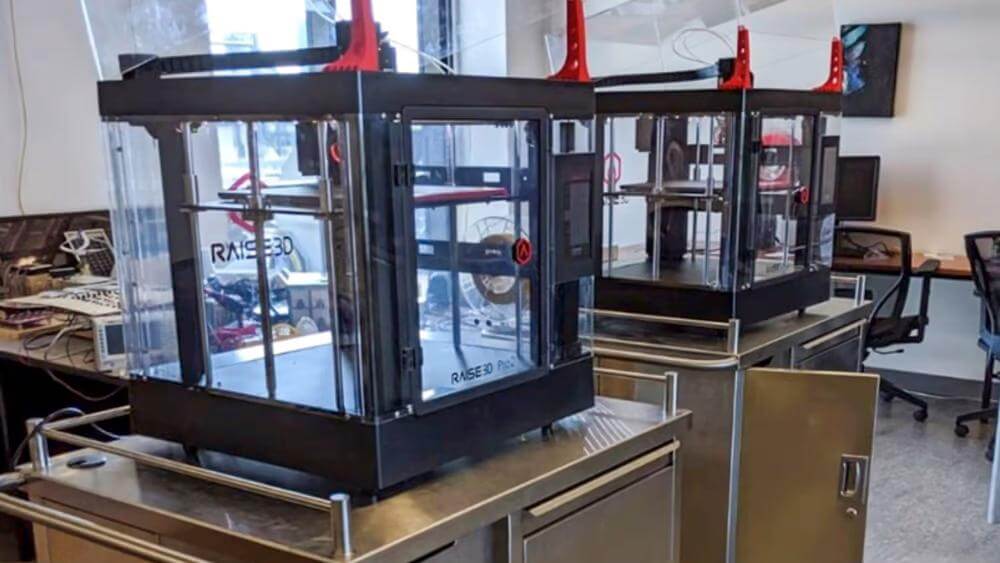

If that's out of your budget, let's look at 3D printers. We'll be using the Raise3D Pro2 as a base and price point for our size, so we're looking at other similarly sized machines for comparison.

From an SLS perspective, the bottom line is around $10,000, but for any build volume close to 300mm in X, Y, and Z, it shoots up to around $100,000. With SLA machines, the problem is not the price. You can get a decent machine for around $2,000. These runs are around 300mm x 150 x 400, but to get closer to 300mm in X, Y, and Z, we need to look more at a machine like the Formlabs Form 3L, which costs $10,000. You can also be limited by the types of materials available to you.

Material costs

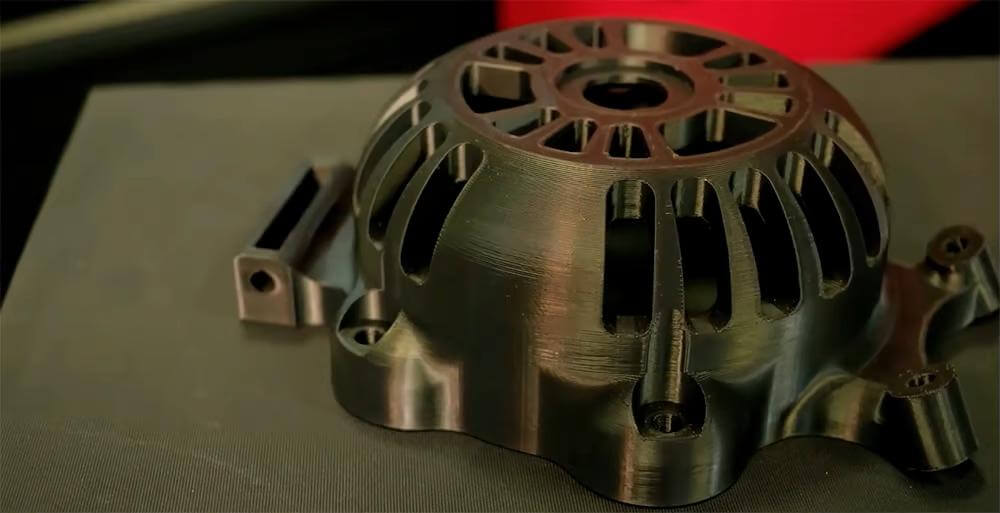

The last thing to consider is the cost of materials, FDM, SLA and injection molding are the most effective for reducing waste during the production of parts, as CNC is more wasteful due to the fact that it is extractive production process. In some cases, SLS powder cannot be reused and must be mixed with fresh powder so as not to degrade the quality of the parts, or even not to be reused, but this seems to be the case with older ones. machines.

So, in terms of this particular part, it takes 45.5 grams of material to print with a 100 % fill and 26.6 grams printed with a standard 15 % fill. Using material that costs about $30.00 per spool, we're looking at costs of $1.37 and $0.80, respectively, for these two fill options. Now, comparing this to our manufacturer estimates, parts production is still over 100 percent cheaper on a comparative basis when looking at FDM printing.

Given that the cost of the Pro2 is $ 4,000, at the above rates with this particular part, we would need to produce 3,000 units and from the savings on these parts alone to fully pay for the Pro2 itself. Of course, it all depends on the part being produced, and these machines are used to produce more than one type of part. The most effective case is for larger scale, one-off prototypes.

As a real-world example, this part pictured above costs approximately $20 in materials when printed in-house. That's $100 cheaper than the estimates I got from our cheapest manufacturer.

Now the price will usually drop if larger quantities of parts are required, so if say all the parts will be one-off productions, then the Pro2 pays for itself in this case within 40 prints. Now this is the cheapest option available, PLA material. If we reinforce it with polyamide, the price difference jumps to $370 per production unit, meaning the Pro2 will pay for itself in just over 10 prints.

On top of that, several other advantages are that owning your own machine gives you absolute control over the construction of the part. In some cases, third parties will only allow you to choose between several resolutions or fill settings.

3D printing versus traditional production - speed.

There is also a "time to run" factor. So when I mass produce these parts with my own machine, here it takes me about 10 days printing time to finish a batch of 50pcs. on one machine with 100 % filling. This is comparable to third party shipping times, but then I get the parts as soon as I print and they don't all finish at once. So instead of waiting around 12 days for 50 parts, I can do 15 every three days and even every two days when we reduce the fill from 100% to 15%. The only caveat in this case is that I have to be there to remove the parts between prints.

Given the cost of production right now, for low-volume consumer parts, for regular use, or one-time use prototypes, owning a 3D printer is the best option. Optimized templates and IdeaMaker - Raise3D's slicing software - allow new users to start printing right away, but also allow for a huge amount of customization and part adjustments if needed, and the scale of the Pro2 and Pro2 Plus ensures you won't be limited in size when it matters most.

Used source of the material - All3dp

0 Comments