3D printing is the answer to the most troubling business challenges today - from cutting costs to standing out from the crowd. Take advantage of the production of supplements now!

We have come a long way since the 1980s in many ways. This also applies to 3D printing. Around its creation, many considered the technology to be pure, but lacked applicability outside the production of large-scale or aesthetic prototypes - also known as rapid prototyping. But that was 40 years ago. 40 years is a long time. Today, 3D printing has reached commercial and industrial viability. This is further evidenced by the fact that the terms "3D printing" and "additive manufacturing" are largely interchangeable today.

Companies in all industries, from soft drinks companies to NASA, have recognized the benefits of Additive Manufacturing (AM). The huge variety of available 3D printers has allowed them to optimize topographies to save resources and improve functionality, to make their parts lighter and more durable with advanced materials, to create complex geometries and internal structures that traditional production simply does not. can produce much more. Simply put, AM can create more complex and optimized parts than any other technology.

But how can manufacturing supplements (AM) help your business become more efficient? In this article, we will introduce you to 10 common business challenges in the form of questions you can ask yourself. If your answer to even one of them is "Yes", you should consider 3D printing.

Question: Does an unpredictable part of the supply chain cripple your productivity when it is expected to arrive?

To build anything, you need the right parts. Unfortunately, supply chains for specialized parts and components can be long, with delivery times ranging from weeks to months. If the parts manufacturer of your choice is busy with other orders, the waiting time may be extended even further. Needless to say, without the parts you can't build anything and the productivity of your business suffers.

3D printing provides an answer to this problem by allowing you to produce the necessary parts yourself. As such, the execution time of the new parts, however, takes a long time to design, print and further process the part, but will certainly be shorter than ordering it from a third-party supplier. In addition, if your parts have previously been manufactured using traditional tools, switching to 3D printing will further reduce execution time, as AM is virtually guaranteed faster than CNC or other processing methods.

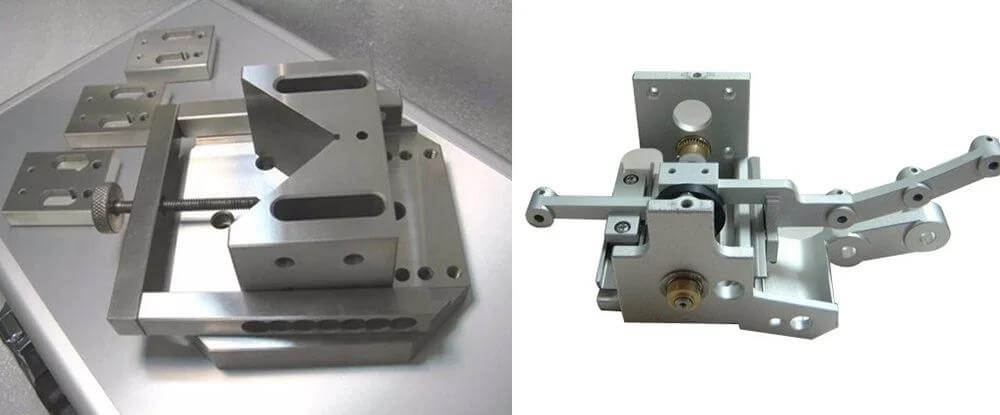

A great example of supply chain optimization through AM comes from Moog Aircraft Group, one of the leading manufacturers of aircraft control systems. Previously, the company purchased the necessary CMM inspection equipment from an external manufacturer with an average lead time of around four to six weeks. Moog has partnered with 3D printing company Stratasys to begin printing ASA thermoplastic luminaires. As a result, the company reduced the delivery time of a new device from weeks to 20 hours. The technology also allows them to test new parts designs in a matter of hours instead of weeks.

Question: Do you use unique or obsolete machines that need expensive spare parts?

Specialized business operations require specialized tools. But this specialization is also a weakness - the stock of spare parts may be limited. It becomes even more difficult if you use old tools that are no longer produced. If a part stops, the spare parts may simply no longer exist on the market.

AM (Additive Manufacturing) facilitates the acquisition of even the most unique spare parts. All you need to create the part is a CAD file and a printer. Materials aren't really a problem - 3D metal printing has reached a point where even small office or workshop-sized machines can produce durable spare parts.

Of course, if you don't have a 3D model, you can't print a file. Fortunately, you can scan the 3D part to create a quick backup. For example, the Dutch 3D printing company Visual First managed to scan and print a distribution cap for Harley-Davidson from 1919 - a part that has not been produced for almost a century.

In a more business-oriented way, Porsche launched its Porsche Classic service in 2018. Many car enthusiasts love their retro Porsche, but this poses a significant challenge to the carmaker. It is incredibly expensive to produce and store these generally obsolete auto parts, given how low demand is. At the same time, the company wanted to please the owners of its vintage cars.

Today, Porsche prints original parts on demand, all thanks to AM. The Porsche Classic service supports more than a dozen vehicles, the oldest model being the Porsche 356. 1948. Now the only problem is for every owner of an old Porsche to decide whether a 3D printed part can be considered authentic enough for their classic car. If you ask Porsche, they can.

Another example of the production of spare parts with 3D printing comes from the German railway company Deutsche Bahn. The company still uses reliable Class 294 locomotives from the 1960s, but their supply of spare parts has long been exhausted. As a result, Deutsche Bahn was forced to obtain spare covers for metal-cast wheel bearings - a process that was months long and expensive. To save time and money, the company turned to Wire Arc Additive Manufacturing, an established 3D printing company. Deutsche Bahn can now produce a 28-kilogram spare bearing cover in just seven hours.

Question: Does it reduce the assembly of components and products in your business?

Due to the limitations of traditional production of metal parts or plastic molding, very complex components have to be assembled from several separate parts. The assembly process loses working time and unnecessarily prolongs production time. Disher, a consulting firm, says briefly, "Assembling a product is nothing but a cost to the company."

AM can completely remove the assembly from the equation. Because 3D printers produce parts layer by layer, they can consolidate several different parts into one component. Of course, this will require a redesign of the part in question, but the time spent on the redesign is nothing compared to what would be lost during assembly. Redesigning parts consolidation brings with it additional benefits - it can significantly reduce the weight of a part, thus leading to additional cost savings.

GE is one of many companies that have succeeded in redesigning parts consolidation. In a great example, the company uses 3D printing to reduce the fuel nozzle from 20 parts in one unit. The new part was 25% lighter than the regular nozzle and was more than five times more durable. "The technology was amazing," said Mohammad Ehteshami, a former head of engineering at GE Aviation who now runs GE Additive, a new business focused on the latest manufacturing techniques, including 3D printing. "The complexity of jet engine design used to be expensive. But the Additive Manufacturing (AM) allows you to improve while reducing costs. This is the engineer's dream. I never imagined that this would be possible. "

Question: Does the weight of parts and products matter to your industry / company?

The hard part is the expensive part. Not only do you have to expend more energy to move it during production, but the end user also suffers from weight. Each extra pound of a Boeing 737, for example, increases operating costs by hundreds of thousands of dollars. As far as consumer goods are concerned, the lighter the products, the cheaper they are to deliver to retailers.

3D printing is the answer you are looking for if you want to reduce the weight of your products. We've already covered this in the parts consolidation section, but combining several parts into one isn't the only way to put your parts on a diet. AM allows the replacement of materials with lighter ones that provide similar or better mechanical properties, such as the use of advanced plastics instead of metal.

In addition, the structure of the parts can be optimized by iterative design and topology optimization. This process uses a computer program controlled by AI (artificial intelligence) to process hundreds of different iterations of the design. The end result is a part whose geometry provides the best possible physical properties, while reducing the material used to a minimum through organically designed elements and carved or lattice internal structures.

GE Aviation realizes these advantages with its 3D printing bracket for an aircraft engine. Through partnerships with 3D Systems and Frustum, the companies optimized the bracket topology through iterative design. The final part weighs the stunning 70% less than the original, while retaining all the structural and mechanical properties.

Another example comes from the 3D printing company MX3D, which uses the ABB robot arm in its printers. MX3D developed and printed a spare part for the robot, which was 50% lighter than the original. The weight savings were realized through an iterative design that turned the previous hard, rectangular part into a mesh-like shape that resembled an organic bone structure. This is also linked to the self-production of spare parts - now MX3D no longer has to rely on ABB to acquire spare parts, but can instead print them internally, saving time and money.

Question: Does outsourcing unique tools, welding and assembly devices or custom parts cost you too much?

Uniqueness comes at a price. The limitations of traditional production are directly expressed in high production costs when it comes to complex, custom parts. Not only that, the exported parts have to be sent to you, so you have to pay for delivery as well. And if the part is not pre-assembled, your staff must assemble it, further extending the time to market.

If this is the case for you, 3D printing is the solution you are looking for. With an internal 3D printer you can produce extremely complex parts at a very low cost in your own facility. Not only will you save on production and transportation costs, but you'll also improve productivity with faster lead times. Even if you are not looking to get your own printers, using a third-party printing service will be cheaper than traditional production due to the nature of 3D printing and usually the lower weight of the parts produced.

Airbus realizes these advantages by producing 3D printed parts to overcome the gaps left after a new cabin layout. The airline had previously ordered plastic injection molded parts, but that was expensive. Using internal FDM 3D printing, Airbus is now able to produce these parts itself. Production costs are not only lower, but the company claims that they can optimize the parts without additional costs. The new internal grille structure of the parts makes them lighter with 15%, which further leads to lower operating costs for the aircraft.

But when it comes to reducing costs, you may want numbers. One of the world's largest manufacturers of interior automotive components, TS Tech, has partnered with 3D printing company Stratasys to implement FDM printing to create controls. The fixtures were pre-stamped with aluminum. According to TS Tech toolmaking instructor Stephen Mollet, 3D printing reduces the cost of any device by 31%.

Question: Waiting for prototypes to be produced hinders the creativity of your team?

Your team has managed to create a potentially revolutionary new parts design. Everyone is excited when the design is sent for production and then keeps rolling their thumbs for weeks before the prototype product arrives at your office. Finally, they can repeat this process over and over with each iteration of the design.

Does that sound familiar to you? If that happens, can we remind you that AM (Additive Manufacturing) was originally called "rapid prototyping?" The 3D printer can create a prototype design in a matter of hours. Even very large components and parts can be printed in a day or two. If the prototype does not pass the test, all you have to do is modify the CAD file and print the part again.

Depending on the printed part and the printer used, your team could at best go through two or even three iterations of the design per day. Additionally, using iterative design software, you can run the program's AI through hundreds of iterations over several hours to find the optimal part geometry.

As an added bonus, faster prototyping means that your team will arrive at the final, marketable design much faster. 3D printing significantly reduces launch time, allowing you to launch new products at a faster pace.

The American car manufacturer Ford uses 3D printing in the design process of the Mustang Shelby GT500 in 2020. According to Matt Titus / Ford Performance vehicle engineer /, the use of tools for design simulation and fast 3D prototyping "drastically reduces" the time and money required for the development of the car.

"The most promising designs were printed in a matter of days, not months," Titus said. "For example, more than 10 front-splitter rockets were printed and tested, some with minor modifications to refine their design, with multiple versions of parts sent simultaneously to evaluate the track."

Ford, of course, is a huge company, but the same principles apply when moving to a smaller scale. A simple desktop 3D printer will allow even Startups from one person to quickly produce prototypes to demonstrate their innovative ideas with a physical product.

Question: Are you trying to differentiate your products from the competition?

Today's consumers have more options than ever when choosing which products to buy. It is vital that your product stands out. For example, how many times have you walked into a store for toothpaste and wondered what exactly is the difference between all the same-looking packaging? Customers who cannot distinguish one product from another can leave without making a purchase.

If your business is facing this challenge, the freedom of design that 3D printing offers is exactly what you are looking for. AM is able to create geometries that are simply impossible through traditional manufacturing. Built on the printing bed layer by layer, the 3D printed product should not take into account difficulties from special tools, trimming or other similar factors. The only geometric constraints that apply are the print size and the minimum detail characteristics.

Cisco, a technology company, wanted to create devices and products that were more aesthetically pleasing than conventional interactive routers and Wi-Fi transmitters. Thanks to 3D printing, the company has been able to incorporate design changes into its products, replacing rectangular, bulky designs with glossy lines and curved surfaces. This is partly due to the rapid prototyping that allows 3D printing; if the original design does not work, Cisco can quickly change the CAD model to achieve the desired functionality while retaining the unique, marketable design elements.

"It's inspiring to see what my team can do with what the world has always received as a basic black box. Designs like these don't just appear on a computer screen. Because design is so important, 3D printing is an important part of our product strategy, ”said Eskild Hansen, head of Cisco's European Design Center.

Question: Will offering each customer a personalized product give an advantage to your business?

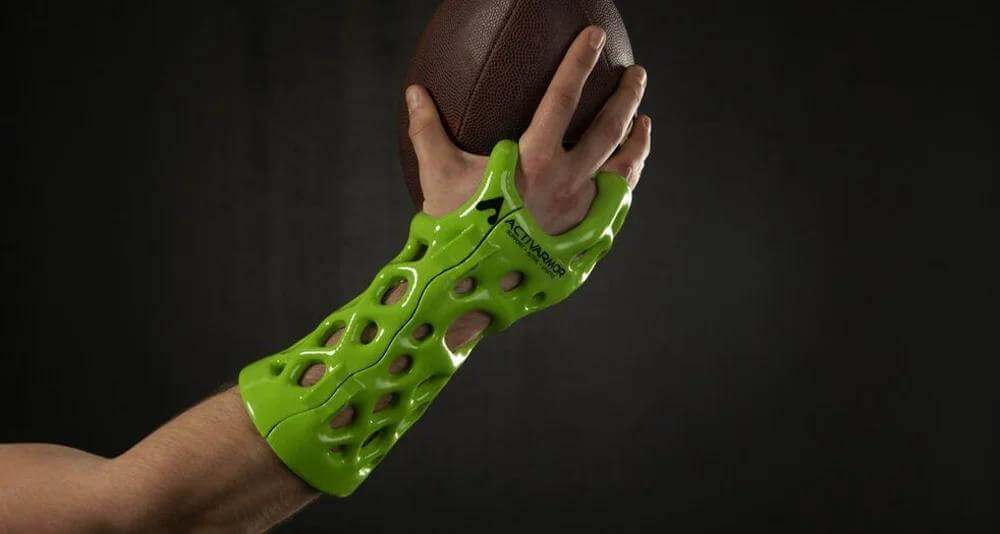

There are two very good reasons to offer customers a custom product. First of all, everyone loves to feel unique and the opportunity to offer products tailored to the needs and tastes of the customer is a great selling point. Second, some industries - especially medical - require products to be customized according to the specific situation of the recipient. The prosthesis, for example, must be precisely adapted to the recipient's body.

AM allows companies to quickly customize products. Since the product only exists as a digital 3D model before printing, it is easy to incorporate small changes, especially cosmetic ones. 3D printing also eliminates the need for specialized tools, allowing businesses to provide customizable items at a low cost scale.

According to business consulting company Deloitte 36%, consumers are interested in personalized products. From this group 20% are willing to pay top for a personalized product. If your business can offer even a small selection of predefined customization options, you can quickly increase the end result.

On the consumer side, French audio equipment maker Askja Audio has created the Origin 3D hybrid amplifier. The use of 3D printing allowed them to offer users adaptive surface coatings of the amplifier, such as a simulated skin texture.

"Using additive manufacturing to allow customers to customize their own design is a huge advantage. It also forms part of Askja's unique selling proposition, as no other audio systems company has ever designed its end products with additives, ”said Askja founder Didier Kwak.

In the medical field, the British prosthesis company UnLimbited uses 3D printing to create its highly adaptable, lightweight and inexpensive hand prosthesis. The company says the prostheses can be customized in both size and appearance. Aimed specifically at children, UnLimbited has produced prostheses with emblems, graphics and colors of superheroes, football teams and more.

Another UK company, Align Technology, manufactures the Invisialign brand with transparent tooth aligners. The company has been using 3D printing for more than 10 years. CAD models for the devices are based on 3D scanning of the patient's mouth. Using 3D printing, the company is able to produce 320,000 custom aligners every day. Align also says that 3D technology allows the patient to see the expected results as a 3D model and adjust them according to the patient's wishes before ordering the dental alignment.

Question: Is your business concerned about waste, high use of raw materials or the environment?

The opportunity to present your products as an environmentally friendly alternative is a great marketing tool. According to GreenPrint 78%, consumers prefer to buy responsibly manufactured products. At the same time, by switching to environmentally healthy production, you will protect the planet.

But even if your industry is not particularly committed to the environment, reducing material waste leads to cost savings. For example, with a production method removed as CNC tooling, more than 50% of the material used may end up as chips on your factory floor. Even a practical zero-waste production method, such as injection molding, is not a solution when working with low production volumes. This results in the production of more parts than necessary, loss of materials and money for surplus stocks. Overall, the US Department of Energy says AM can reduce material costs by up to 90%.

Because 3D printing is an add-on technology, it produces very little waste. 3D printers deposit material only where necessary, bonding layers to create a product from virtually nothing. Therefore, it does not suffer from material waste such as CNC production. It is also suitable for small volume production, which gives it an advantage over injection molding and other similar technologies. 3D printing also uses less energy than any of these methods.

With some printer technologies - especially powder - it is also possible to recycle materials that have not been included in the product. You can simply vacuum the spare dust from the print bed. Depending on your materials, you may even be able to grind and reuse unsuccessful prints.

Finally, AM allows you to use typology optimization and generative design to maximize the mechanical properties of your parts while discovering the geometry with the lowest resources. The result is a strong, functional part with significantly lower material consumption.

The 3D printing material supplier Apium has created a cranial implant for patients with severe head injuries. Such implants are usually made of PEEK thermoplastic, which results in a significant amount of waste. By 3D printing the implant, Apium reduces material consumption by 89%, while reducing production costs by 73%. The 3D printed implant is also more durable than the human skull.

Rogerie, a Canadian manufacturer of recycled products, recycles local plastics into 3D printing materials. With this approach, the company is able to reduce plastic waste in its community, while recycling this waste into functional everyday products.

Question: Can changing the material of your products improve their functionality or your business operations?

If you've always used the same material for your products and it works, the idea of switching to another material may sound pointless. But there is always room for improvement, and new advanced materials can improve the mechanical functionality of your products or production line - even if it doesn't seem obvious at first.

Many 3D printing companies and additive manufacturers are constantly researching and developing new materials that provide higher mechanical functionality than traditional material options. Some 3D printed plastics, for example, may be more durable or chemically resistant than many metals. Improving the mechanical properties of your parts, tools or machines makes them more durable. This can increase customer satisfaction and sales or reduce downtime and allow you to reduce maintenance and spare parts costs.

The Dutch confectionery company The Chocolate Factory experiences constant downtime with its packaging machines, having to change metal parts several times a year. The endless cycle of maintenance costs the company a lot of time and money. The 3D printing company Visual First has developed a spare part made of 12CF nylon, a hard thermoplastic reinforced with carbon fibers. The new material is more durable than metal and provides increased flexibility, making it less likely to break. Even if a breakage occurs, the part will come off cleanly and will not damage the rest of the machine. At the same time, the Chocolate Factory managed to reduce downtime from a month to less than a week with a printer in place and reduce maintenance costs with 60%.

In another example, Avignon Ceramics manufactures probes for aerospace applications from 3D printed ceramics. Used to measure dynamic and static pressure, these measuring probes have traditionally been made of metal. Avignon ceramic probes offer improved functionality, allowing them to measure air velocity at even higher speeds and temperatures - something metal probes can't do. Unlike metal meters, ceramic ones can withstand temperatures up to 2,000 degrees Celsius, in addition to extreme thermal shock.

So, do any of these issues apply to your business? If so, you should seriously consider adopting 3D printing. Whether you want to provide cheaper spare parts, improve the appearance of your products or reduce maintenance costs, the production of additives will prove a quick return on investment.

New printing technologies and materials are constantly being developed. As such, the applicability of 3D printing to various industries is constantly expanding. Even if AM turns out not to be the right choice for your business right now, keep an eye on it - it may soon provide you with just the right parts.

0 Comments