Risky investors write large checks to support innovators in the thriving 3D printing space as it proves to be a viable solution to a number of challenges.

The infusion of $ 150 million in fresh money last week from leading 3D printer maker Formlabs is just the latest eye-catching figure in the rush to return to innovative and proven 3D printing companies. In fact, investors have invested hundreds of millions in 3D printing companies so far in 2021.

Formlabs, the 10-year-old manufacturer of 3D printers for amateurs and businesses, said on Wednesday that it had doubled its estimate to $ 2 billion after a multimillion-dollar funding round led by SoftBank Group's Vision Fund 2.

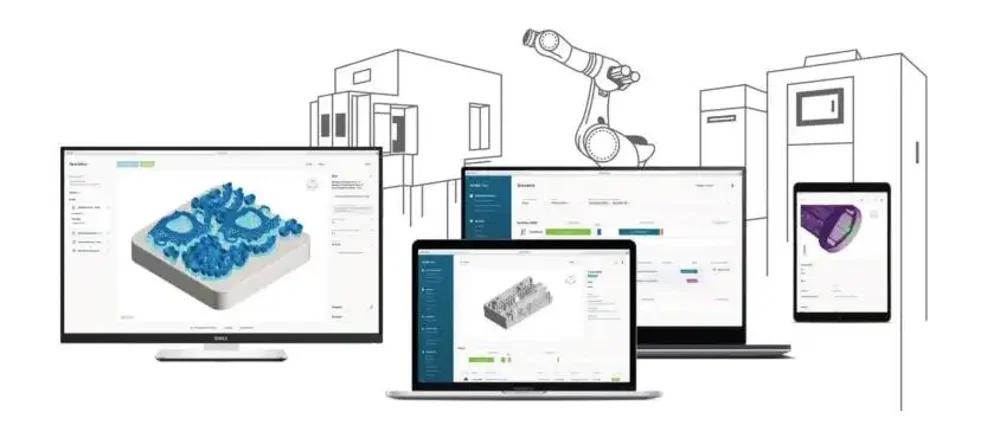

Formlabs says it's "on a mission to expand access to digital factories so everyone can do anything," which obviously sounds like a limitless investment opportunity for supporters. But in fact, parts made with Formlabs printers can be found in your operating room, dentist's chair, car and shoes, with leading companies such as Google, Mayo Clinic and New Balance relying on Formlabs printers to develop, prototype and manufacture finished products. use consumer goods on a scale.

"We believe that the 3D printing industry is currently facing unprecedented growth and changing the way products are manufactured," said Deep Nishar, senior managing partner at SoftBank Investment Advisers.

Will this be another 2013?

Nearly 10 years ago, when many 3D printing companies first set up shop and many went public, technology had to be the next big thing. "Every house and factory in America would have a 3D printer." That, of course, didn't happen, and investors in the segment dwindled. So what's different now?

One difference may be investing in relatively well-established companies. Formlabs has sold tens of thousands of machines, has a solid and growing customer base and a strong reputation for quality and service.

"Where others have promised printers capable of mass-producing and producing quality parts for end use, Formlabs has delivered," said Max Lobovsky, CEO and co-founder of Formlabs.

Other differences in the current manufacturing environment for additives compared to a decade ago include more modern technology, lower costs and the clear importance of 3D printing as a solution to supply chain problems exacerbated by the pandemic.

"Fans of [3D printing] are betting that the pandemic has forced companies to rethink the way they produce goods in the long run, with some seeking more land production to avoid supply problems or shortages," Laura said. Foreman for the Wall Street Journal.

Consider this space for more funding opportunities as 3D printing continues to grow at a breakneck pace in the main supply stream.

0 Comments